- Konu Başlıkları

- Speed, Convenience and Efficiency: The Effects of 3D Printing on Production

- The Contributions of 3D Printing to Industrial Production

- Cost and Time Savings Are Very Valuable!

- Advantages of 3D Printing in Industrial Production

- Mass Production with 3D Printing: The Production Method of the Future

- Contribute to Industrial Production with 3D Printing

Speed, Convenience and Efficiency: The Effects of 3D Printing on Production

3D printing technology continues to revolutionize the world of industrial production. This rapidly developing technology makes production processes more efficient while also enabling the design of more customized and original products. The contributions of 3D printing to industrial production are starting to be felt in more and more sectors every day.

Now, let's examine the effects of 3D printing on production, the production process with 3D printing and mass production with 3D printers.

[widget-131]

The Contributions of 3D Printing to Industrial Production

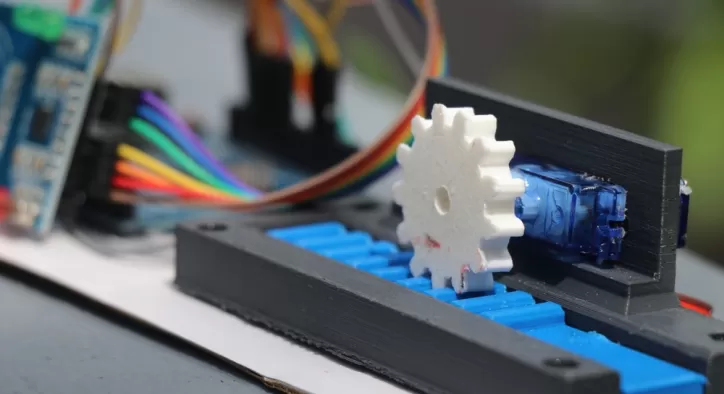

3D printing, unlike traditional production methods, allows the creation of a three-dimensional object from a digital file. This process creates a shape by adding material layer by layer, and this method is particularly suitable for prototype production, small series production and customized products. The contributions of 3D printing to industrial production make production processes more flexible and faster, leading to significant changes in many sectors.

First of all, the most striking effect of 3D printing on production is the freedom it provides in design. Design options that are limited with traditional production methods gain great flexibility thanks to the production process with 3D printing. Designs can be made much more complex and original. In addition, the acceleration of production processes saves time and cost.

The ability to mass produce with a 3D printer has an important place in industrial production. In traditional production methods, there may be high initial costs for molds and other equipment. However, the advantages of 3D printing in industrial production include the possibility of low-cost production. This provides a great advantage, especially for small-scale production and prototypes.

Cost and Time Savings Are Very Valuable!

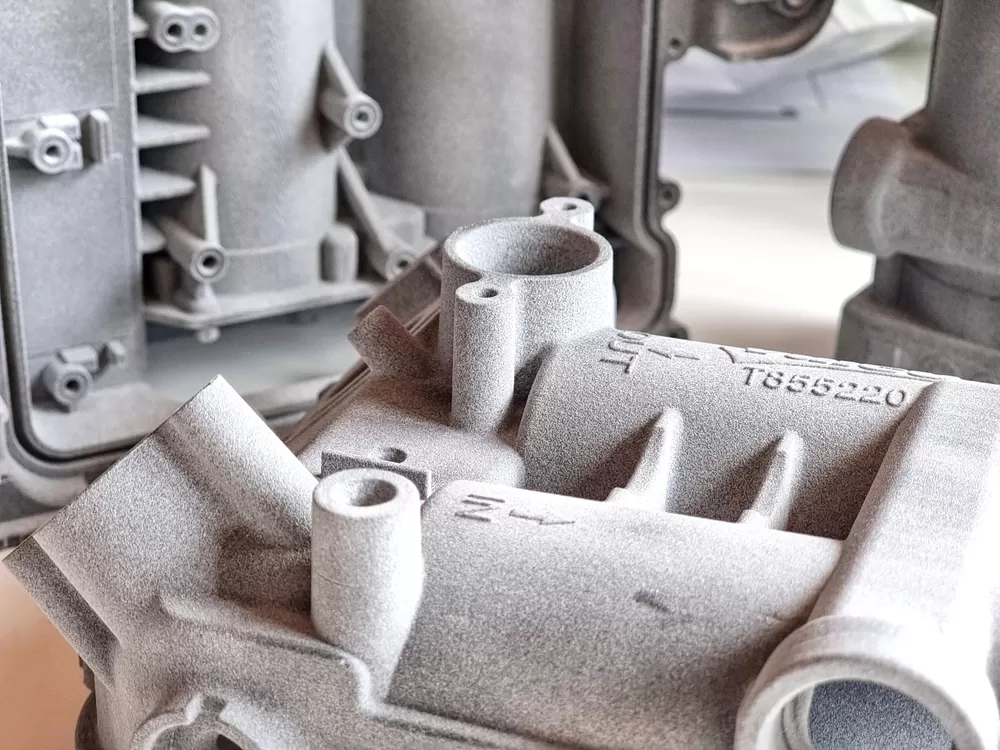

The effects of 3D printing on production are very important in terms of providing cost and time savings. In traditional production methods, molds and other equipment are required, especially for large and complex designs. This equipment can slow down the speed of the production process and create high costs. However, thanks to the production process with 3D printing, the need for mold production or extra equipment is eliminated. This shortens the production time and reduces costs.

The possibility of mass production with 3D printing makes it possible to produce at much lower costs in industrial production. The ability to mass produce with a 3D printer makes low-cost production, which was previously only possible for factories that produce high volumes, accessible to small-scale manufacturers. In this way, especially start-ups or companies that will make limited production can produce without incurring high investment costs.

Advantages of 3D Printing in Industrial Production

The advantages of 3D printing in industrial production lead to revolutionary changes in many sectors. These advantages consist of factors such as faster production, lower costs, customizability and environmental sustainability.

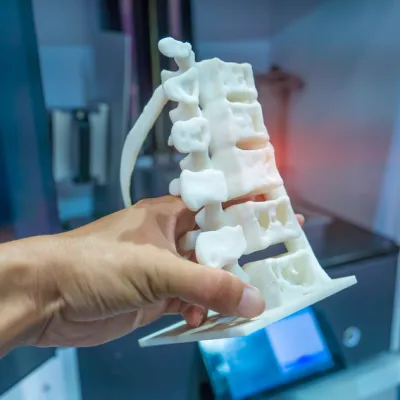

Rapid Prototyping and Design Changes: In traditional production methods, producing a prototype can take time. Among the contributions of 3D printing to industrial production is that prototypes can be produced quickly and at low cost. Changes in the design can also be made instantly, which significantly speeds up the design process.

Customizability: The effects of 3D printing on production allow each product to be customized. The production process with 3D printing allows the production of special designs for each customer. This is a significant advantage, especially in industries such as medical, automotive, fashion and interior design. Mass production with a 3D printer enables the customization of each product, supporting the production of high-quality and customer-oriented products.

Less Waste and Environmental Sustainability: In traditional production methods, excess material use and waste can pose a significant environmental problem. The advantages of 3D printing in industrial production include layer-by-layer production and using only the required amount of material. This reduces environmental impact and provides more sustainable production.

Lower Start-Up Cost: The production process with 3D printing offers low start-up costs, especially for small-scale production. While investments such as molds, production lines and large machines are required in traditional production, such costs are eliminated when mass producing with a 3D printer. This offers a great opportunity for new entrepreneurs and small businesses.

Mass Production with 3D Printing: The Production Method of the Future

The capacity to mass produce with a 3D printer has been an important step for the future of industrial production. While traditional production lines only work efficiently in high-volume production, efficiency increases in low-volume production thanks to the effects of 3D printing on production. The contributions of 3D printing to industrial production allow companies to meet demands more quickly and flexibly.

When mass producing with a 3D printer, each product can be designed from a digital file and produced individually. This allows the same design to be produced repeatedly and increases efficiency in the process. In addition, the effects of 3D printing on production reduce faulty production rates thanks to automation and digitalization.

[widget-136]

Contribute to Industrial Production with 3D Printing

The contributions of 3D printing to industrial production have become a technology that is rapidly adopted and implemented in many sectors. By using this technology, you can make your production processes faster, more flexible and more environmentally friendly. The production process with 3D printing always allows you to produce at lower costs and with higher quality. The ability to mass produce with a 3D printer makes your production process more efficient and offers you great advantages.

If you also want to produce with 3D printing and produce original and high-quality products, it is important to choose the right company. As a company specializing in the effects of 3D printing on production, we offer solutions that suit your needs. You can also contact us to speed up your production processes, reduce your costs and obtain customized products. The contributions of 3D printing to industrial production will take your business one step ahead.