3d production

Production

We Bring Ideas Together with Technology and Bring Them to Life!

We meet your advertising and promotion needs with high quality standards in our 1600 m2 production facility equipped with technologies such as CNC printer, industrial SLA and 3D PLA machine.

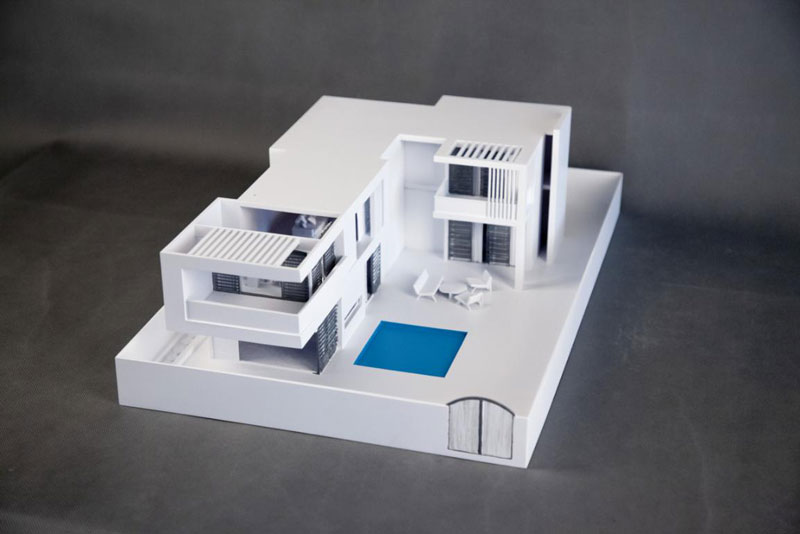

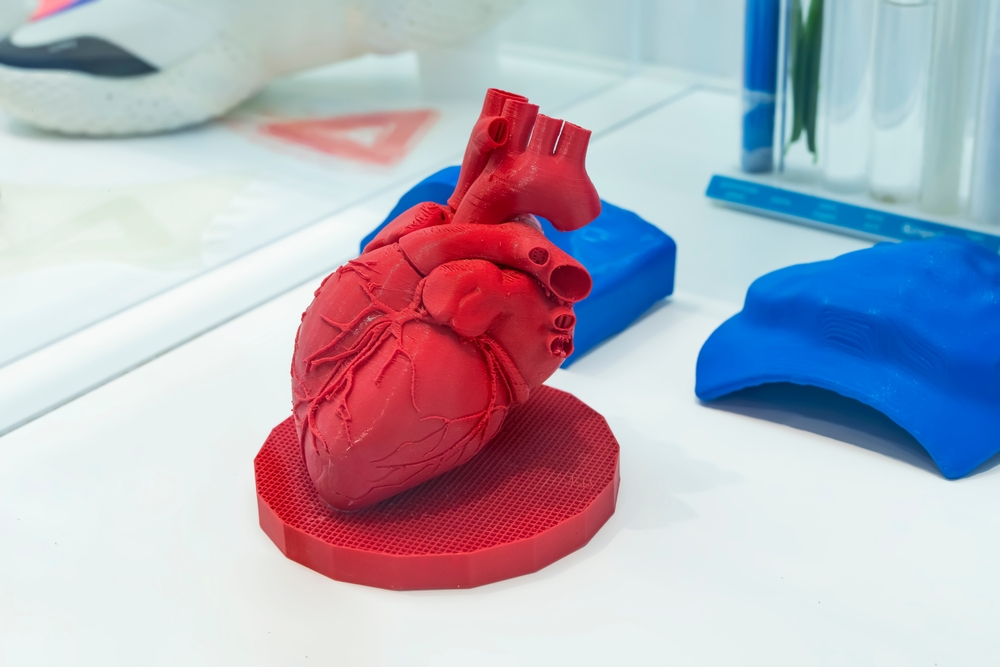

We produce architectural and city sculptures, dummy, mock up and 3D advertising models, stands and stages, automotive parts, industrial prototypes, construction modeling, health equipment and many different productions with a fast, meticulous and flawless workmanship. With our team of experts, we design your products, create CAD drawings, make molds, produce them and deliver them to you after completing the final processes.

With our 40 years of sectoral experience, 3D and CNC technologies, our experienced team and our broad vision, we have all the qualifications to prepare your products completely!

More than 3000 3D Advertising and Industrial Design Projects

Design

We make digital drawings of sculptures, dummies, advertising models, 3D objects and all your other projects, and put the product you have in mind on paper with creative designs!

With our expert designers, we make the complex designs, fine details and production stages of your productions visible with CAD drawings and improve the designs by learning your aesthetic and functional expectations. We determine the material, size and surface properties and present them for your approval. We make a difference in 3D designs with high precision and care.

As Erlas Global, we clarify all the steps before printing and consider every detail to deliver your product to you without any problems.

Modeling

We move on to the modeling phase, where a digital or physical prototype of the product we have designed is created...

3D modeling, which we do using computer-aided design (CAD) software, allows us to visualize in advance how the part to be produced will look and what materials will be used by determining the dimensions, geometric shapes and all technical details of the product. At this stage, we exchange ideas and create prototypes with the exact form and functionality you want, which serve to optimize the final design in terms of both aesthetics and functionality.

Accurate modeling is critical for the production process to run smoothly. That's why we pay attention to this step!

Molding

In the molding phase, we ensure that the model has a physical appearance. We speed up our work in the production process with a tangible, visible mold.

We reflect all the details of the model to the mold in the molding process, which we perform with various materials (plastic, sand, metal, resin, etc.) depending on the type of product, production method, sector, space, size and aesthetic preferences. Since the quality of the mold affects the quality of the part to be produced, we control each step one by one.

The molding process, which is the most useful process for mass production, is ideal for sectors that want to produce a large number or partial products.

Production

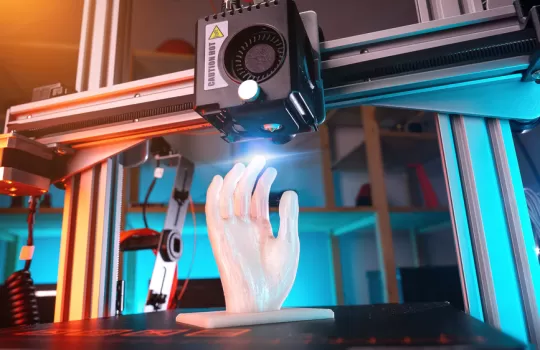

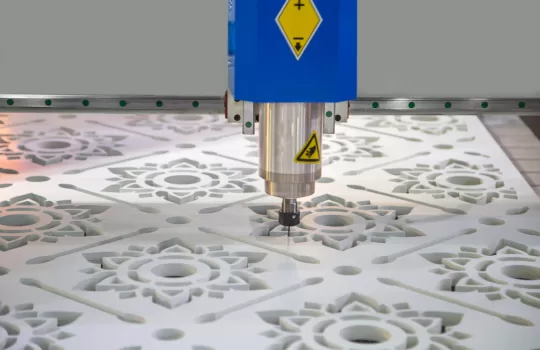

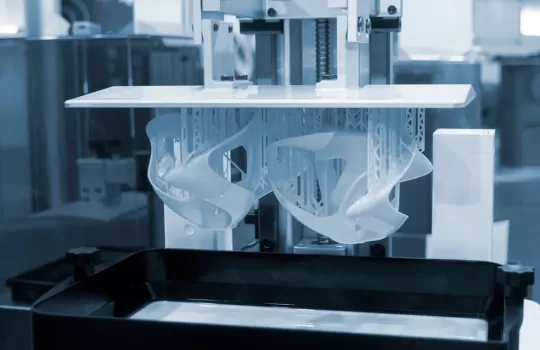

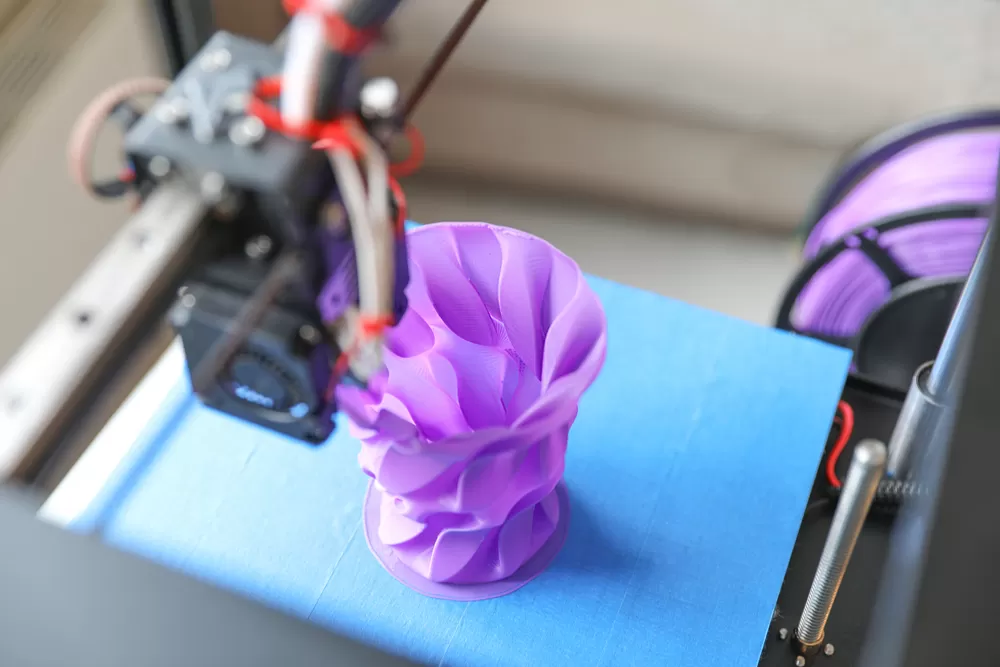

As Erlas Global, we produce quality products in our production center, which includes technologies such as CNC printer, industrial SLA and 3D PLA machine.

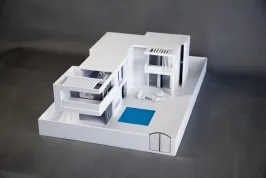

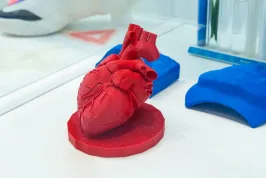

We produce artist sculptures, city and architectural sculptures, 3D objects, 3D advertising models, figures and characters, stands, stage and period decors, shoe molds, building models, military prototypes and many other creative and functional productions by using different production techniques such as CNC machining, production with 3D printers, casting or injection depending on the design and production material of the product.

After the production is completed, we remove the product from the mold and, if necessary, we follow steps such as polishing and sanding in the finishing stage. We deliver durable, precise and high quality products.

Assembly

We carry out the assembly of large parts or multi-part products flawlessly with our experienced team.

In the final stage, we assemble the parts that are separated into parts during production or produced from different materials. In this process, which is critical to ensure the functionality and stability of the product, we obtain a seamless product with methods such as fasteners, welding, gluing or screwing.

We offer ready-to-use products to our customers and end our commitment with Erlas Global's 40 years of experience.

Our Services - What Do We Produce?

As Erlas Global, we provide services in different fields from advertising and promotion to marketing, from industrial manufacturing to prototyping. We produce sculptures of artists, special sculptures for cities, 3D dummy and mock up applications. Take a look at our wide range of production options...

Our Technologies - How Do We Produce?

In our production processes, we use various 3D production technologies for different sectors and offer solutions to suit your needs. With Large CNC Printer, we perform high-precision cutting and engraving processes in large-scale projects, and with the industrial SLA (StereoLithography) machine, we can precisely produce parts that require complex and fine details. Thanks to our 3D PLA technology, we manage the rapid prototyping and production processes of plastic-based products with an economical and environmentally friendly approach. With these technologies, we add quality and speed to a wide range of industrial projects!

Our Projects - What Have We Done with 3D Printer?

Take a look at what we have produced with 3D technology for industrial manufacturing, engineering and architecture projects, automotive parts, medical products, defense industry equipment and other sectors! With 40 years of Erlas Global experience, leave your projects in expert hands!

40+

Years of ExperienceExperienced 3D architectural theming and advertising company in its field.

300+

3D Advertising ModelsSpecial 3D models and characters, dummy and mascot productions for companies.

400+

Monument and City ArchitectureColorful and remarkable architectural designs that add movement to life.

250+

Stage Decoration ApplicationStage and decoration applications for the most watched TV series and movies.