3d printer productions

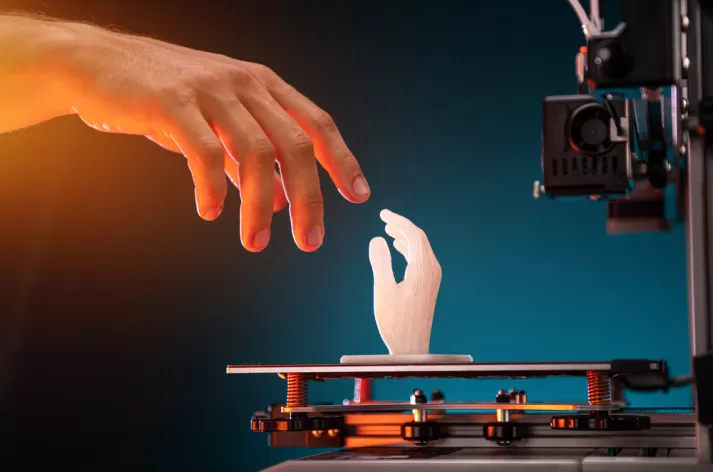

3D Printer Production

Innovative, Flawless and Useful!

We make your dreams come true by offering 3D solutions in every field from industrial manufacturing to engineering projects, from automotive parts to education sector.

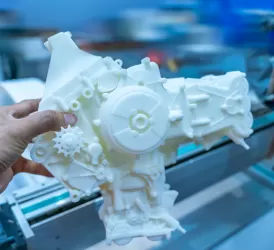

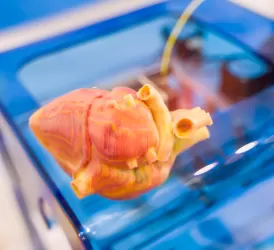

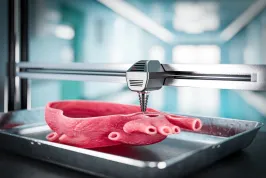

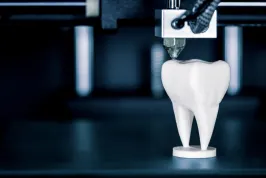

We produce the parts and models needed in aviation, construction, health, food, automotive, art and many other fields with our latest technologies. We provide high precision and quality prototype, 3D object, mock up, prop and character production for your projects with our large CNC printer park, industrial SLA machine and 3D PLA machine. We promise smooth and detailed productions for your complex and detailed manufacturing needs!

You tell us what you have in mind, leave the rest to us... We prepare prototypes of all your designs, greatly increase production efficiency while offering economical solutions. You are in the right place for 3D printer productions...

The Best Service in 3D Modeling and Production

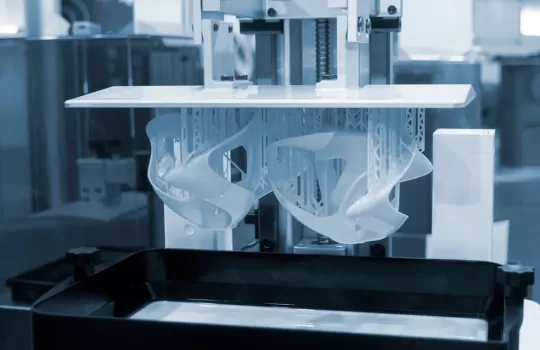

Our Technologies - How Do We Produce?

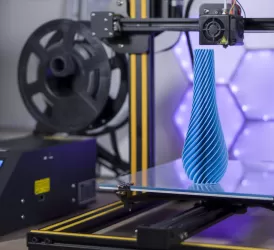

In our 3D printer production processes, we offer solutions suitable for your needs by using various 3D production technologies for different sectors. With Large CNC Printer, we perform high precision cutting and engraving operations in large-scale projects, and with industrial SLA (StereoLithography) machine, we can precisely produce parts that require complex and fine details. Thanks to our 3D PLA technology, we manage the rapid prototyping and production processes of plastic-based products with an economical and environmentally friendly approach. We add quality and speed to a wide range of industrial projects with these technologies!

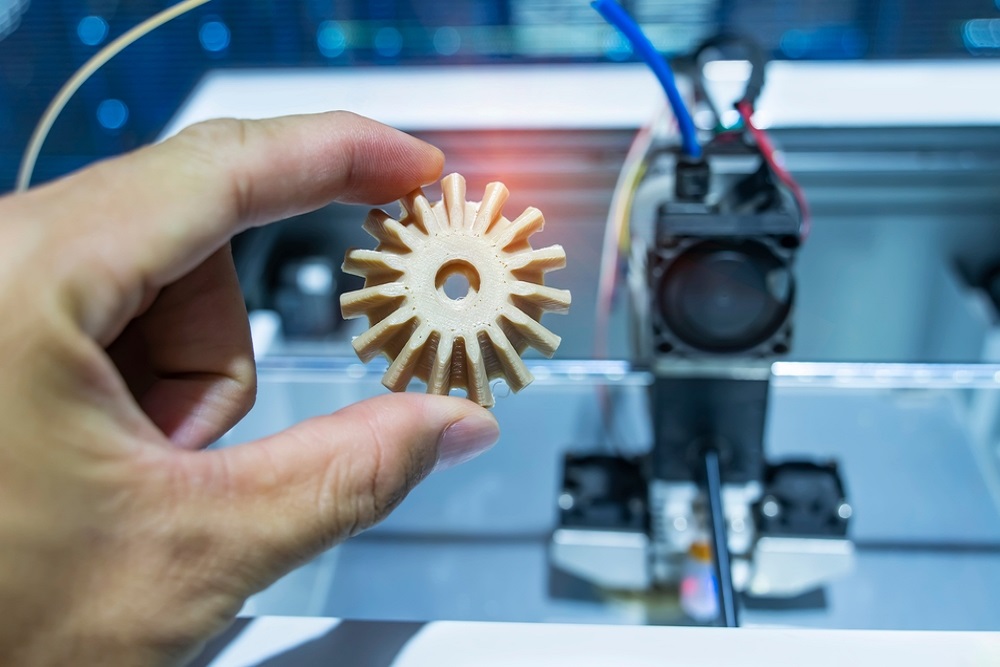

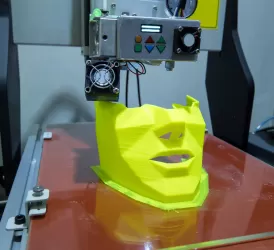

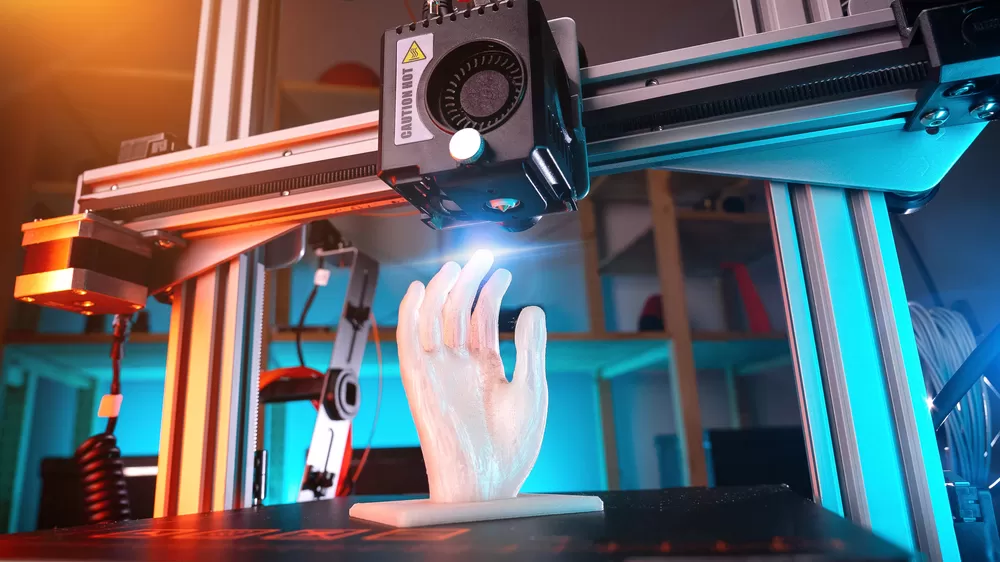

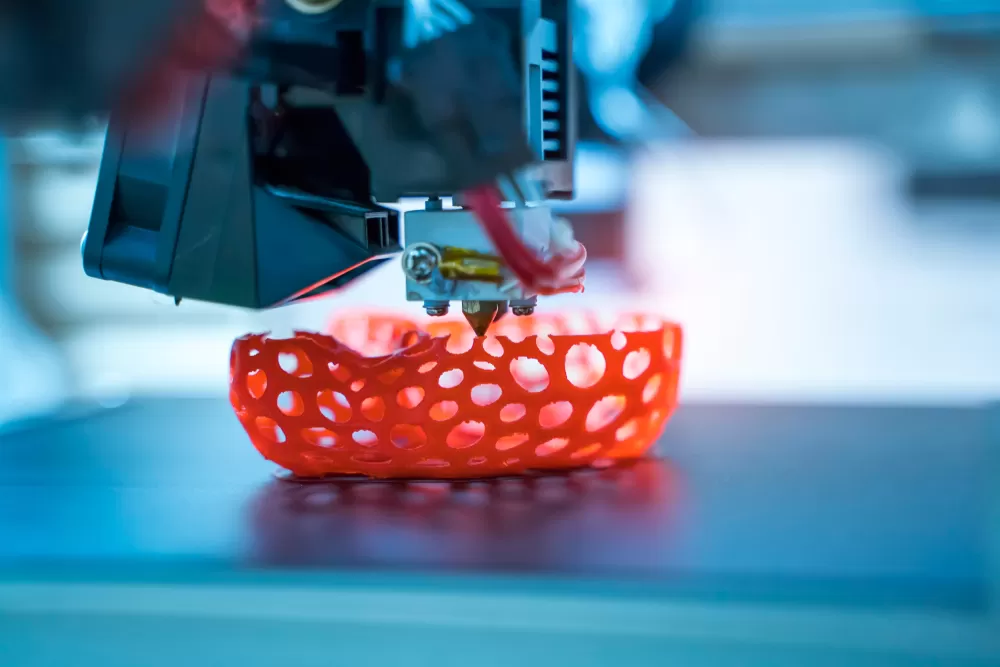

3D Printing

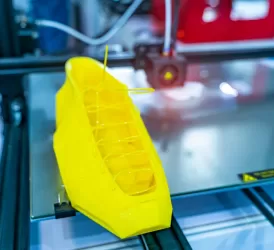

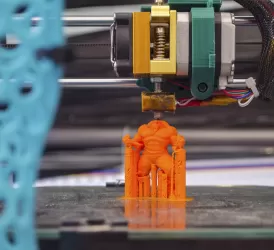

Thanks to 3D printing, which is the process of precisely producing three-dimensional objects, we meet the needs of different sectors and enable the easy production of parts that are considered impossible or difficult to produce. All that is needed is a CAD drawing!

With 3D printing, which can be used in electronics, defense - industry, education, dental, hobby, clothing, architecture, medical, health, construction and many more sectors, it is possible to produce parts quickly and economically with minimum waste. 3D production starts with a detailed CAD file transferred to 3D printing software, the software analyzes this drawing and separates it into layers, a suitable choice is made for the object from different materials, and the 3D printer gradually creates the object. After a short time, it is possible to see the three-dimensional design in a tangible form.

As Erlas Global, we also work in collaboration with our customers and prepare prototypes, parts and models using the latest 3D technologies at every stage of the production process. Trust 3D printing technology to test your products in the real world, optimize your design and reduce your production costs!

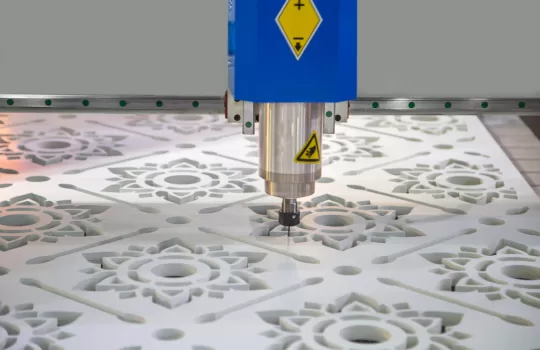

CNC Machining

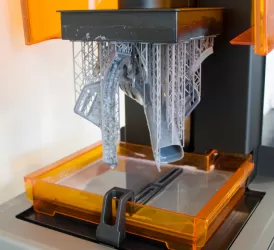

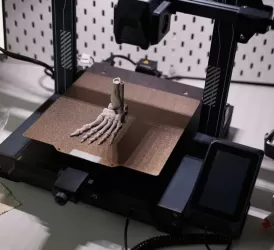

With CNC manufacturing technology that provides high precision, repeatability and efficiency, we work easily on all materials such as iron, steel, aluminum, wood, plexiglass and similar materials, and produce special solutions for works that require detail and precise measurements.

The production process of CNC machines, which produce more precise production than 3D printing with tolerances as low as 0.001 mm, is similar to 3D printing. The CAD drawing containing the measurement and geometric data of the part is transferred to the software, and suitable cutting tips, milling cutters or other processing tools are mounted on the CNC machine. The material to be processed is placed in the machine and the CNC machine processes the material precisely by applying the commands specified in the program. After the processing is completed, the burrs remaining on the workpiece surface are cleaned and final surface treatments are applied when necessary.

We prepare your high-precision parts in our technological production facility that performs special processing for different parts with CNC milling and CNC turning methods, and provide you with the advantage of standard and continuous quality manufacturing. Choose CNC for large-scale production in sectors such as automotive, aviation, medical and electronics…

Finishing Services

We perform finishing processes that will complete the production quality in the final stage of 3D printer production.

It provides a flawless surface in the painting stage, we pay attention to the fact that the desired color is the same tone on all surfaces in the color matching step, we smooth the surface with sanding and polishing, we use vapor polishing to eliminate defects in hard-to-reach areas. We create a shield against rust and corrosion by sandblasting the produced parts with sand, water or different materials. Finally, we use pad printing technology to print 2D patterns on interior and exterior surfaces that are difficult to print.

As Erlas Global, we work with a professional team from design to final control to create flawless models and prototypes in our production area where a large CNC printer, industrial SLA machine and 3D PLA machine are located.

Our Projects – What Have We Done with 3D Printer?

Take a look at what we have produced with 3D technology for industrial manufacturing, engineering and architecture projects, automotive parts, medical products, defense industry equipment and other sectors! With 40 years of Erlas Global experience and 3D printer production, leave your projects to expert hands!

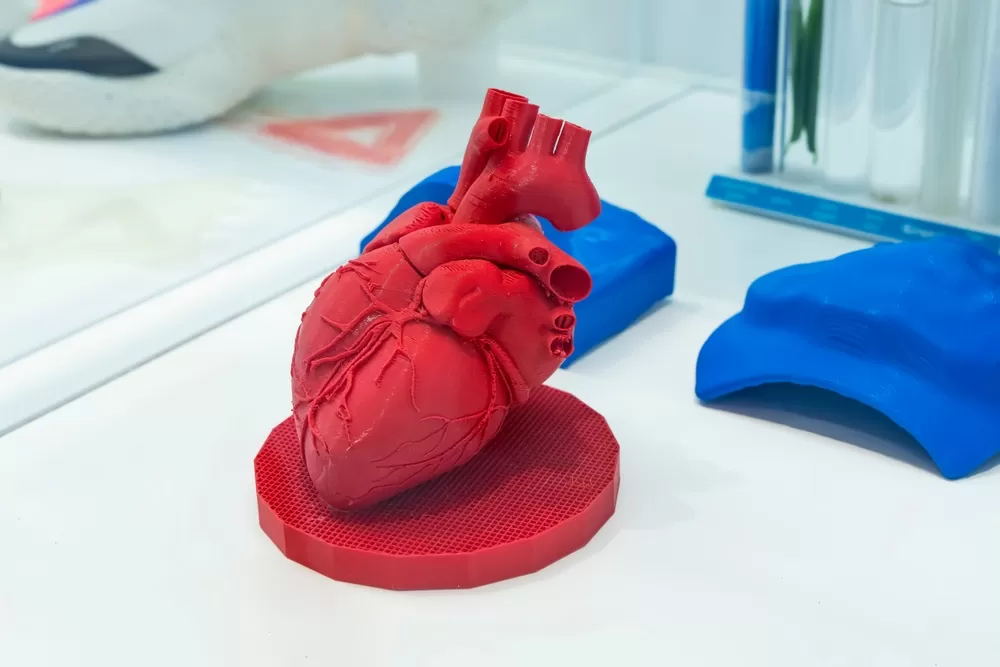

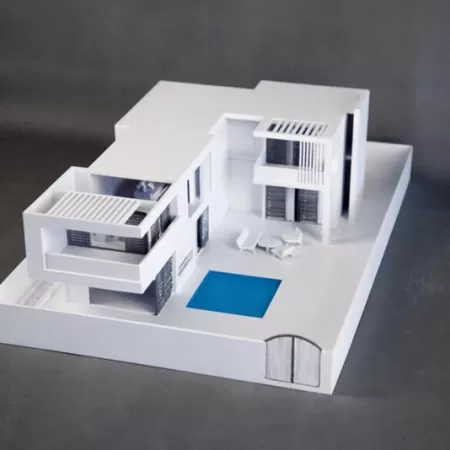

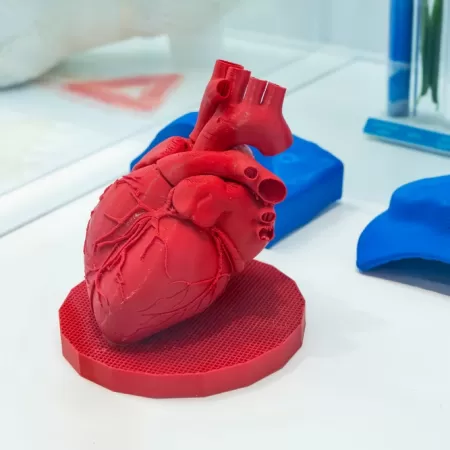

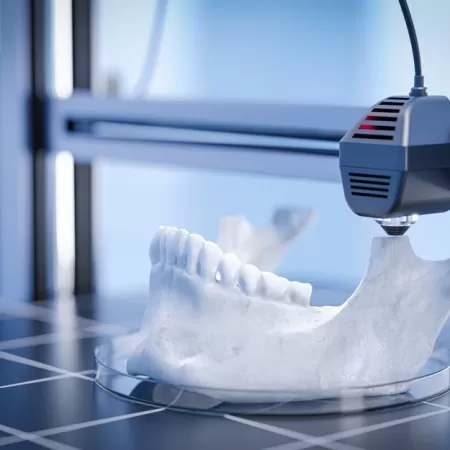

Application Areas – 3D Productions Special for Every Sector!

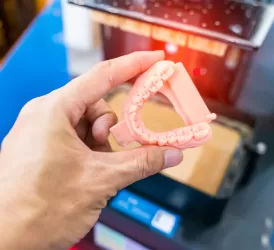

We prepare 3D objects, advertising models, characters, stands, shoe models, building models, dental molds, medical parts, scenes and decorations and promotional products for almost every sector, especially for the shoe and accessory, construction, health, education, defense, industry, dental, food, automotive, electronics sectors!

Quality and Technology in 3D Printer Production!

Minimize your costs by taking advantage of new generation production technology…

Get Information40+

Years of ExperienceExperienced 3D architectural theming and advertising company in its field.

300+

3D Advertising ModelsSpecial 3D models and characters, dummy and mascot productions for companies.

400+

Monument and City ArchitectureColorful and remarkable architectural designs that add movement to life.

250+

Stage Decoration ApplicationStage and decoration applications for the most watched TV series and movies.