- Konu Başlıkları

- We Answer Your Questions About 3D Printing Control Test and Painting Stages!

- 1-Which Stages After 3D Printing?

- 2-How is 3D Printing Visual Control Performed?

- Important!

- 4-How to Check 3D Printing Dimensions?

- 5-Does 3D Printing Post-Processing Include Durability Testing?

- 6-What Abrasive is Used for 3D Printing?

- 7-What is 3D Printing Painted With?

- 8-Why Coating After 3D Printing?

- 9-What are the Things to Consider in the 3D Printing Surface Smoothing Step?

- 10-How to Complete the 3D Printing Test Phase?

We Answer Your Questions About 3D Printing Control Test and Painting Stages!

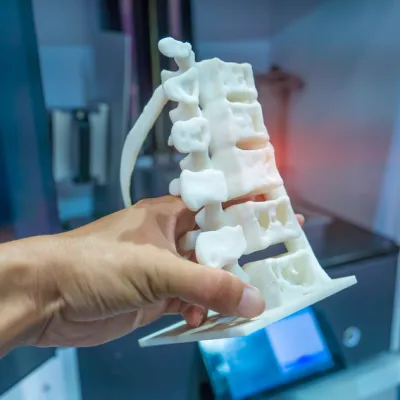

3D printing places apply some control stages after 3D printing. Control, testing and surface treatments are carried out in order for 3D printing products to fully respond to the needs and expectations of customers and to obtain error-free results. Measuring the aesthetic and functional effects of the product after 3D printing is also important in improving print quality. So, what are the post 3D printing processes? Here are all the curiosities and answers...

[widget-131]

1-Which Stages After 3D Printing?

Quality control processes start after 3D printing. Post 3D printing processes are important to recognize existing errors and to check whether the production responds to the needs. The 3D printing control phase, which includes visual, dimensional and tolerance control; mechanical structural 3D printing test phase and surface control are applied as 3D post-printing processes.+

2-How is 3D Printing Visual Control Performed?

The 3D printing test phase first starts with visual control. The general appearance of the part is examined and any errors are detected. The number of layers and shifts are checked, if there is a deviation in the axis of the printer, it is noticed during the 3D printing test phase. After 3D printing, the part is examined for gaps.

Important!

If there is a shift in the printer axis, the part may be deformed!

3-3D Printing Control Phase What is Tolerance Control?

Tolerance control after 3D printing; It is done to understand whether the part maintains a certain level of precision. Especially in industrial applications, it is important to check whether the part is within a certain tolerance range.

4-How to Check 3D Printing Dimensions?

Dimensional measurement is also included in 3D printing post-processing. Caliper and micrometer tools are used to compare with the dimensions in the CAD model. This 3D printing control stage, where important surfaces such as holes are measured, should not be skipped.

5-Does 3D Printing Post-Processing Include Durability Testing?

Another 3D printing control stage is mechanical and structural testing. At this stage, where the quality and durability of 3D printing products are tested, the conditions that the product will undergo in use and the loads it will be exposed to are simulated. Strength tests such as impact tests, tensile and compression tests and function tests must be performed after 3D printing.

6-What Abrasive is Used for 3D Printing?

One of the processes after 3D printing is surface treatment. Sanding is done in cases where layer lines become clear after 3D printing. For the sanding process to improve the appearance, coarse sandpaper is used for large roughness and fine sandpaper is used for fine and delicate roughness. In this way, the product is prepared for paint and varnish after 3D printing.

7-What is 3D Printing Painted With?

Another stage among the post-3D printing processes is 3D printing painting. In order to improve the aesthetic appearance after 3D printing, painting is done in accordance with the printing technology and material type used. After the 3D printing control phase is completed, 3D printing painting can be done with acrylic, spray, airbrush, primer, powder and epoxy paint.

8-Why Coating After 3D Printing?

Post-3D printing processes include coating and varnishing stages. With coating and varnishing processes, the surface is protected and supported to have a shiny structure. Especially for parts to be used outdoors, protective coatings must be applied after 3D printing. Several layers of varnishing can also be applied to increase the gloss level.

9-What are the Things to Consider in the 3D Printing Surface Smoothing Step?

After measuring the surface roughness with a device called profilometer, the surface smoothing process is started after 3D printing to increase mechanical performance and create a more aesthetic appearance. Before proceeding to the processes after 3D printing, the support structures, if any, should be cut manually with tools such as utility knives or pliers. If there are support materials that need to be dissolved in chemical solution, they are removed by melting method and then proceed to the sanding stage. Surface treatments vary according to the material, printing technology and the intended use of the part.

[widget-136]

10-How to Complete the 3D Printing Test Phase?

The surface quality, color matching and general appearance of the product are examined. Its conformity to functional requirements is tested, whether its dimensions are correct is checked with precision measuring instruments and the 3D printing test phase is completed.