- Konu Başlıkları

- 3D Printing for Prototyping and Production: The Future of Modern Manufacturing

- What is 3D Printing and Why is it Important in Prototyping Processes?

- Fast and Efficient Solutions with 3D Prototyping Manufacturing

- 3D Printing and Prototyping: In Which Sectors Is It Used?

- 3D Printing and Prototyping in the Automotive Sector

- 3D Printing and Prototyping in the Healthcare Sector

- 3D Printing and Prototyping in the Aerospace Sector

- 3D Printing and Prototyping in the Architecture and Construction Sector

- 3D Printing and Prototyping in Education

- The Future of 3D Printing for Prototyping

- Why Should You Choose 3D Printing for Prototyping and Production?

3D Printing for Prototyping and Production: The Future of Modern Manufacturing

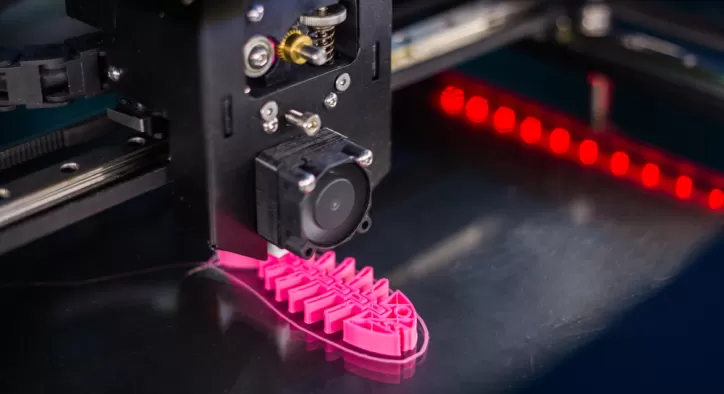

In an era where technology is pushing the boundaries, 3D printing solutions for prototyping and production are revolutionizing production processes. In situations where traditional methods are time and cost-limiting, 3D prototyping increases the production power of businesses by offering speed and flexibility. So why have 3D printing manufacturing processes become so popular?

[widget-131]

What is 3D Printing and Why is it Important in Prototyping Processes?

3D printing is a production technology that transforms digital models into physical objects. Especially 3D printing for prototyping allows designs to be tested and developed quickly. A process that could take weeks with traditional methods can be completed in hours thanks to prototyping 3D printing solutions.

Designs can be tested quickly.

Time and cost savings are achieved in development processes.

Detailed and complex geometries can be easily produced.

Fast and Efficient Solutions with 3D Prototyping Manufacturing

3D prototyping has become one of the cornerstones of the production process. In the process from design to final product, 3D prototype production allows you to detect possible design errors at an early stage. This not only reduces costs, but also makes the production process more efficient.

The main advantages of using 3D printing manufacturing especially for prototyping, are:

Time Saving: Fast production even in complex projects.

Cost Efficiency: Budget control by using only the required materials.

Flexibility and Innovation: Easy modification and development of designs.

3D Printing and Prototyping: In Which Sectors Is It Used?

Prototyping 3D printing solutions offer a flexible and innovative production process shaped according to sectoral needs. It allows each sector to develop customizable products and solutions according to its own dynamics. Here are the sectors where this technology has revolutionized:

3D Printing and Prototyping in the Automotive Sector

The automotive sector is one of the areas that benefit the most from 3D printing technologies for prototyping and production. 3D prototyping offers speed and cost advantages in the process of testing vehicle designs and producing customized parts.

Rapid Design Tests: During the design of a new vehicle model, 3D printing for prototyping allows concepts to be tested quickly.

Customized Parts: Parts with different sizes and features for each vehicle can be produced at low cost with 3D prototype production.

Cost and Time Savings: It provides advantages in terms of both cost and production time compared to traditional methods.

Prototyping 3D printing solutions used in these processes play a critical role in many stages from the design process to final production.

3D Printing and Prototyping in the Healthcare Sector

The healthcare sector is one of the areas where 3D printing technology is most effectively used for prototyping and production. 3D printing is used for prototyping in a wide range of areas, from prosthetics to medical devices, from dentistry applications to surgical guides.

Prosthesis and Orthosis Production: Prosthetics designed according to the individual needs of patients can be easily customized with 3D prototype production.

Surgical Guides: Models used in pre-operative planning can be created with prototyping 3D printing solutions.

Dentistry Applications: Personalized products such as dental molds and implants are produced with high precision with this technology.

3D prototyping improves treatment processes by providing personalized and effective solutions in the healthcare sector.

3D Printing and Prototyping in the Aerospace Sector

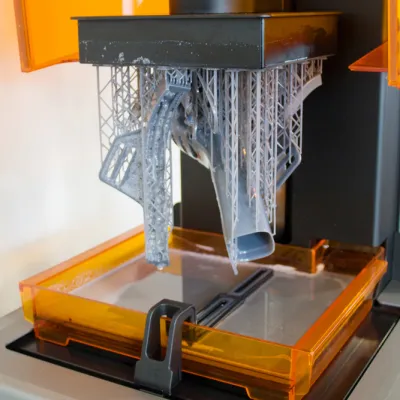

The aerospace sector uses 3D printing technology for prototyping and production in the production of parts that require high precision and durability, encouraging innovation in this sector.

Lightweight and Durable Parts: Parts used in aircraft and space vehicles are produced with lightweight materials thanks to 3D prototype production.

Complex Geometries: Complex structures that are difficult to produce with traditional methods can be easily created with prototyping 3D printing technology.

Cost Advantage: Rapid testing of prototypes at low cost optimizes the budget.

3D printing solutions for prototyping and production used in these processes help the sector adapt to advanced technologies.

3D Printing and Prototyping in the Architecture and Construction Sector

3D printing for prototyping in the architecture and construction sector enables detailed planning and visualization of projects. It makes a great contribution to the design process by creating physical models.

Architectural Models: Scale models of structures can be produced quickly thanks to prototyping 3D printing solutions.

Complex Designs: Details that are difficult to create with traditional methods are easily made with 3D prototype production.

Cost Control: Early detection of errors prevents projects from exceeding the budget.

3D prototyping provides great convenience in the planning and presentation of construction projects.

3D Printing and Prototyping in Education

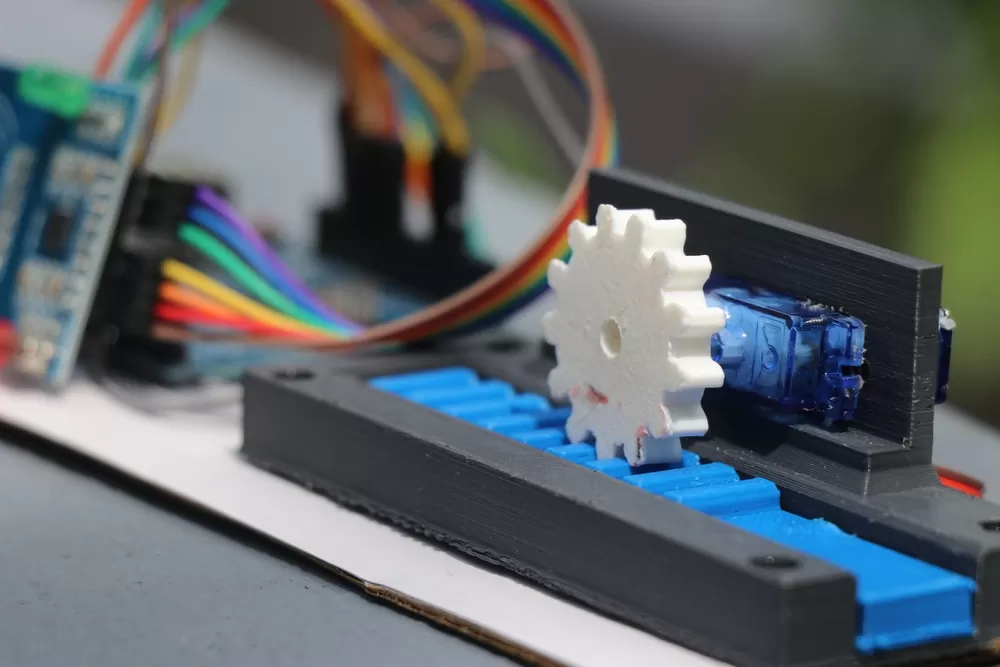

The education sector uses prototyping 3D printing solutions to provide students with tangible learning materials. This technology is frequently used, especially in STEM (Science, Technology, Engineering, Mathematics) education.

Educational Tools: Materials such as molecular models, mechanical parts, and replicas of historical artifacts can be produced with 3D printing for prototyping.

Creativity and Problem Solving: Students develop their problem-solving skills by bringing their own designs to life.

Applied Education: 3D printing for prototyping and production enables the transformation of theoretical knowledge into tangible products.

3D prototyping in education supports learning processes and increases creativity.

3D prototyping in these sectors enables designs to be quickly implemented, saving time and resources.

The Future of 3D Printing for Prototyping

In the future, 3D printing for prototyping and production will find even wider use. Especially with the increasing demand for sustainable production methods, environmentally friendly solutions of prototyping 3D printing manufacturing technologies will be at the forefront. This process, where only the required material is used, minimizes waste.

3D printing for prototyping and production enables businesses to become more competitive with fast and low-cost solutions. It offers flexibility during the testing and development of designs, while making it possible to offer a better product to the end user.

[widget-136]

Why Should You Choose 3D Printing for Prototyping and Production?

If you want to speed up your production processes and make them more efficient, 3D printing for prototyping and production is the ideal solution for you. Be one step ahead of the competition by bringing your designs to life in a short time.

You can take your projects to the next level by getting to know Erlas' 3D solutions right away. Take action today and benefit from the advantages offered by modern production!