- Konu Başlıkları

- Innovative Solutions with 3D Printing Technology in the Aerospace Industry

- Areas of Use of 3D Printing Technology in the Aviation and Space Industry

- Advantages of 3D Printing in the Aerospace Sector

- Why Should You Have It Made with 3D Printing?

Innovative Solutions with 3D Printing Technology in the Aerospace Industry

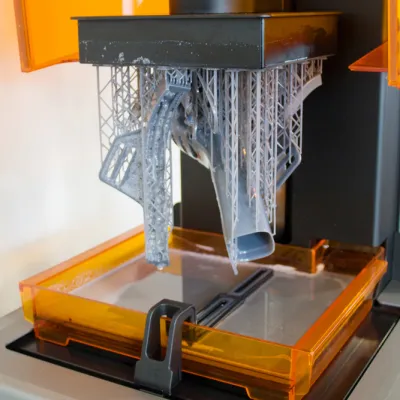

The aviation and space sector is an industry that requires high precision, where safety and durability are at the forefront. These sectors are areas where costs are high, time is of critical importance and each component must be designed and manufactured perfectly. However, in recent years, 3D printing has revolutionized the aviation and space industry and offers the innovative solutions these sectors need. 3D printing for space and aviation reduces costs by accelerating production processes, increases performance by providing design flexibility and ensures flight safety.

Now; We will touch on how 3D printing in space and aviation, rapid prototyping, unquestionably durable and cost-effective solutions make significant contributions to the sector. If you are also looking for innovative solutions in the aviation and space sector, be sure to continue reading our article to learn how you can improve your production processes by getting to know our 3D printing aviation and services…

[widget-131]

Areas of Use of 3D Printing Technology in the Aviation and Space Industry

3D printing technology for space and aviation finds application in a wider range than ever before. The use of 3D printing in the aviation and space industry provides great convenience, especially in the production of aircraft components and space vehicles. The ability to produce custom parts on-demand with 3D printing is paving the way for innovative designs and cost-effective solutions in both space exploration and aviation. 3D printing use in space and aviation offer effective solutions in many areas from rapid prototyping to mass production.

1. Production of Light and Durable Parts

One of the biggest advantages of 3D printing aviation technology is the lighter and more durable production of parts used in aircraft and space vehicles. Compared to traditional production methods, design optimization can be made in parts with 3D printing. In this way, aircraft and space vehicles become more efficient and fuel consumption decreases. In addition, lighter parts increase the performance of the vehicle while reducing transportation and assembly costs.

The use of 3D printing in space and aviation allows various geometric shapes to be easily produced depending on the complexity of the parts. Such complex designs can be much more difficult and costly to make with traditional manufacturing techniques.

2. Rapid Prototyping and Testing Processes

3D printing in the aviation and aerospace industry is an excellent solution for rapid prototyping. The rapid production of prototypes allows engineers to quickly make changes and improvements to the design. Prototyping with traditional methods can be time-consuming and expensive. However, thanks to 3D printing for space and aviation, designs can become physical in a few hours.

This rapid prototyping process allows designs to be tested and the performance of developed components to be evaluated at earlier stages. 3D printing applications, especially in aviation, accelerate test processes, thus shortening project duration and reducing costs.

3. Spare Part Production and Low Volume Production

In the aviation and space sectors, spare part production can be quite costly and complex. However, with 3D printing aviation technology, spare parts that are rarely used or have difficult production processes can be produced quickly and at low cost. Especially in aircraft maintenance, producing only necessary parts instead of defective parts saves time and reduces operational costs.

3D printing for space and aviation optimizes the production process and makes spare part production more flexible. In addition, the ability to produce only parts according to need also significantly reduces warehouse costs for large-scale production.

4. Custom Designs and Customized Components

3D printing for space and aviation enables the production of customized designs and parts. This allows the design of parts that are perfectly suited for each of the vehicles used in the industry. At the same time, customized components and parts can be produced for specific tasks. 3D printing applications in aviation allow the creation of special components for each aircraft, rocket or spacecraft.

Advantages of 3D Printing in the Aerospace Sector

The costs of the aviation and space industry have always been a major concern. The use of 3D printing in aerospace provides significant cost savings compared to traditional production methods. 3D printing in the aviation and space industry offers an excellent solution for producing high-quality parts with lower production costs, less labor and less raw materials.

3D printing use in space and aviation has opened new horizons for manufacturing complex and customized parts. In addition, 3D printing aviation technology also provides savings in maintenance and part replacement processes in the long term. Producing spare parts only when needed significantly reduces stocking and transportation costs. In addition, the use of 3D printing in aerospace provides the following advantages:

1. Design Flexibility and Advanced Technology

3D printing for aerospace allows designers to create highly complex and unique parts. 3D printing applications in aviation allow parts to be optimized not only functionally but also aesthetically. Such unique designs, which cannot be made with traditional production techniques, are made possible by 3D printing. This flexibility allows for the rapid development of innovative projects in the aviation and aerospace sector.

2. Time Saving and Rapid Production

Thanks to 3D printing for space and aviation, the design process is accelerated and production times are shortened. With traditional production methods, the production of a component can take weeks or even months. However, with rapid prototyping and 3D printing, this period can be completed in a few days. This allows projects to be completed faster and adapts to the dynamic nature of the sector.

3. Targeted Performance

In the aviation and aerospace industry, 3D printing ensures that the parts to be produced are designed according to targeted performance requirements. This is especially important for critical components. 3D printing provides full control over the durability, lightness and functionality of each part used in aviation, aircraft and space vehicles.

[widget-136]

Why Should You Have It Made with 3D Printing?

If you decide to use 3D printing in the aviation and aerospace industry, you can benefit from the latest innovations in the sector, produce your designs more flexibly and quickly, and significantly reduce your costs. 3D printing use in space and aviation is an excellent technology for both prototype production and production of small quantities of special parts.

Our company specializes in high-quality prints for the 3D printing aviation and space sector. We have the power to produce any part you need with 3D printing and support you at every stage of your projects. By offering the most suitable solutions for you, we enable your projects to be realized quickly, efficiently and economically.

The use of 3D printing in the aviation and space industry not only allows you to obtain high-quality products, but also allows these processes to be realized more quickly and economically. Contact us for innovative solutions in 3D printing for space and aviation and carry your projects into the future.