- Konu Başlıkları

- Three-Dimensional Prototyping for Fast and Efficient Solutions

- What is Prototype Production with a 3D Printer?

- Advantages of Rapid 3D Prototyping

- Customized Products and Fast Response to Customer Requests

- More Complex Designs and Detailed Models

- In Which Sectors Can Prototype Production with 3D Printers Be Used?

- Why Should You Have Prototype Production with a 3D Printer?

Three-Dimensional Prototyping for Fast and Efficient Solutions

With the rapid development of technology, product development processes have also experienced a major transformation. The time-consuming and costly nature of traditional prototype production methods has led to the emergence of technologies such as prototype production with new generation 3D printers. Now, businesses can quickly turn their ideas into concrete, test their designs and manage their production processes more efficiently. Three-dimensional prototype production offers revolutionary solutions in many sectors, especially in terms of speed, cost and flexibility.

Now, let's examine the prototype production process with 3D printers in detail and explain how this technology provides an advantage for businesses. With rapid 3D prototype production, you can launch your products faster, detect design errors at an early stage, and reach the final product at a lower cost. In addition, thanks to the opportunities offered by three-dimensional prototyping technology to businesses, you can make your production processes more flexible and respond to customer demands faster.

[widget-131]

What is Prototype Production with a 3D Printer?

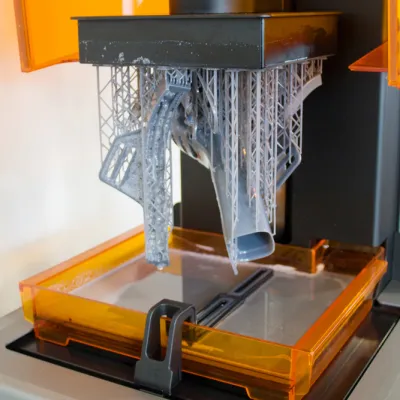

Prototype production with a 3D printer is the process of creating a physical model by printing digital designs in three-dimensional layers. This technology offers a much faster and more flexible production process compared to traditional production methods. Three-dimensional prototype production refers to this technology used to create the first example of any product or design. Designers, engineers, and manufacturers can make their ideas tangible, test their designs, and make changes if necessary, thanks to rapid prototype production with 3D printers.

Traditional prototype production methods are often time-consuming and costly. Casting, molding, and hand-made production techniques can lead to high costs and long production times. However, rapid 3D prototype production is radically changing this process. Prototyping with 3D printers allows you to complete all stages of the product from design to finalization in shorter periods of time and at lower costs.

Advantages of Rapid 3D Prototyping

Rapid 3D prototyping is much faster than traditional methods. After the design is created in a digital environment, the prototype production process with a 3D printer can take only a few hours or a few days. This allows designers to perform tests and receive feedback after the prototype is physically produced. Thanks to three-dimensional prototype production, you can notice design errors at an early stage and make your corrections quickly.

Rapid prototype production with 3D printers is much more cost-effective than traditional production methods. This process, which requires less labor and materials compared to molds, castings or other manual production processes, significantly reduces the production costs of businesses. This helps especially small and medium-sized businesses to work more efficiently. In addition, thanks to low-cost prototyping, more prototypes can be produced and different designs can be tested.

Prototyping with a 3D printer provides great flexibility for changes to be made in the design. With traditional manufacturing methods, when a design change is made, a new mold or changes to the production line are often required. However, with rapid 3D prototyping, small changes to the digital design can be reflected directly in the printer. This flexibility offers more freedom in the design process and allows for faster correction of errors.

Customized Products and Fast Response to Customer Requests

Three-dimensional prototype production offers the opportunity to respond to customer requests and needs more quickly and flexibly. Changes or customizations requested by customers can be easily made during the prototype phase. This is a perfect solution especially for personalized products or limited production series. Rapid prototype production with 3D printers allows manufacturers to offer more customized products in a shorter time.

More Complex Designs and Detailed Models

Prototype production with 3D printers enables the production of complex and detailed designs. Prototypes with details that are too fine to be produced with traditional methods can be produced with rapid prototype production with 3D printers. This provides a great advantage especially in products that require aerodynamic designs, organic shapes and fine details. No matter how complex your designs are, the three-dimensional prototype production process reflects these details in the finest way and enables realistic and functional models to be obtained.

In Which Sectors Can Prototype Production with 3D Printers Be Used?

Prototype production with 3D printers is a technology that can be used in almost all industries. Rapid prototyping with 3D printers accelerates product development processes in every field, especially in the automotive, aviation, medical, electronics, consumer products and many other sectors. Since this technology makes the design process faster, more efficient and flexible, it encourages innovation and helps companies bring products to the market faster.

Especially in the automotive sector, three-dimensional prototype production allows vehicle parts to be produced and tested quickly. While prototype production is carried out for implants, prosthetics and medical devices in the medical sector, the electronics sector can develop more functional and high-quality products thanks to prototype production with 3D printers.

[widget-136]

Why Should You Have Prototype Production with a 3D Printer?

If you want to develop a product or turn your design into reality, prototype production with a 3D printer may be the ideal solution for you. Offering a fast, low-cost, flexible and efficient production process, this technology offers great opportunities for businesses of all sizes. Rapid prototype production allows you to detect errors in the design process early and increases the quality of the final product.

With three-dimensional prototype production, your designs can move from the idea stage to the production stage more quickly. In addition, with this technology, you can respond to customer demands faster, produce customized products and develop more innovative designs. Thanks to prototyping with 3D printers, you can increase the efficiency of your production processes and reduce your costs. If you want to take your work a step further with rapid 3D prototyping with 3D printers, you can contact us and get detailed information about special solutions for you!