- Konu Başlıkları

- Investing in the Future with High Precision and Personalized Designs

- Working Principle of 3D Printing Technology in Jewelry

- What are the advantages of 3D printing for the jewelry sector?

- 1. High Precision and Detailed Designs

- 2. Personalized Product Design

- 3. Rapid Prototyping and Production Process

- 4. Low-Cost Production

- 5. Innovative Designs and Creativity

- 3D Printing Application Areas in Jewelry

- Provide a Competitive Advantage with 3D Printing in Jewelry

Investing in the Future with High Precision and Personalized Designs

The rapid development of technology is reshaping the production processes of every sector. 3D printing in jewelry is a technology that transforms production methods in the sector and enables brands to be more creative, fast and efficient. In addition to traditional jewelry techniques, 3D printing offers great opportunities for the jewelry sector. Jewelry production with 3D printers is becoming increasingly popular in order to meet customers' personalized product demands, test designs with faster prototypes and make production processes more efficient.

Now, let's take a look at how 3D printing technology works in jewelry, the advantages it provides to the sector, its application areas and the opportunities it offers to jewelers. If you are operating in the jewelry sector and want to learn more about jewelry applications with 3D printers and take your business a step further, this article is for you!

[widget-131]

Working Principle of 3D Printing Technology in Jewelry

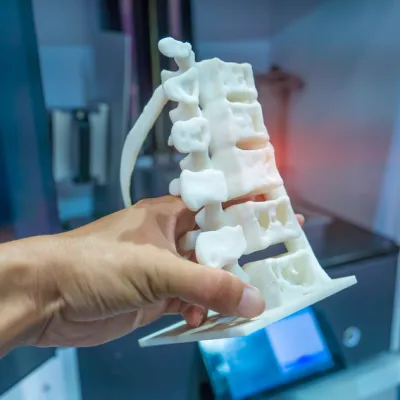

3D printing has created a great revolution for the jewelry sector. While handcrafting and mold use are common in traditional jewelry production, jewelry production with 3D printers accelerates this process in a digital environment. Jewelry applications with 3D printers enable your digital designs to be transformed into real objects.

3D printing technology in jewelry creates objects by adding materials layer by layer. Materials such as liquid resins, metal powders and plastics are generally used in jewelry. These materials allow jewelry designs to be produced with high precision. Designers create their designs using 3D modeling software in a computer environment and these digital models are sent to the 3D printer. The printer produces the details, shapes and metals of the jewelry with high precision by transforming the design into reality in layers.

What are the advantages of 3D printing for the jewelry sector?

Companies that make jewelry applications with 3D printers work on jewelry and jewelry projects. The advantages of 3D printing in jewelry are as follows:

1. High Precision and Detailed Designs

One of the biggest advantages of 3D printing in the jewelry sector is that designs are produced with very high precision. While some details can be difficult with traditional methods, even details that require fine workmanship can be processed flawlessly thanks to jewelry production with a 3D printer. 3D printing jewelry production allows the perfect design of especially fine lines, small stones and complex geometric shapes. Thus, jewelry that requires very fine workmanship can be produced without any loss in your designs.

2. Personalized Product Design

3D printing technology in jewelry allows you to produce personalized designs according to customers' requests. Jewelry applications with 3D printers allow you to create unique products such as special collections, personal gifts and named jewelry. Producing original jewelry designed like a work of art in line with customers' requests will add value to your brand.

For example, when designing a couple's engagement rings, you can add special details for both people and offer a completely personalized product. The 3D printing jewelry sector provides great flexibility to both the designer and the customer. This helps brands gain a competitive advantage.

3. Rapid Prototyping and Production Process

3D printing in jewelry also offers great advantages in terms of speed. In traditional jewelry production methods, handcrafting, mold making and long production times are required for each design. However, thanks to jewelry applications with 3D printers, designs can be prototyped and tested very quickly. Designs are created quickly in a digital environment and jewelry production is carried out quickly with 3D printing.

In this way, jewelers can offer new designs to their customers in a shorter time and shorten production times. In addition, changes that may occur in jewelry designs can be easily made. This allows jewelers to do their jobs more efficiently and effectively.

4. Low-Cost Production

3D printing jewelry sector offers low-cost production opportunity. In traditional production methods, mold production, raw material usage and labor costs are quite high. However, jewelry applications with 3D printers reduce these costs to a great extent. Jewelry production with 3D printing is more economical, especially for small-scale production. Jewelers can produce jewelry in small batches and increase product variety according to their demands.

5. Innovative Designs and Creativity

3D printing in jewelry allows designers to use their imagination more freely. Jewelry applications with 3D printers make it possible to produce complex designs that were previously difficult to make. The design freedom, which is limited in traditional jewelry techniques, is spread over a wider range with 3D printing.

Highly customized designs, geometric shapes, minimalist lines and abstract designs can be designed for many different styles of jewelry. With the 3D printing jewelry sector, jewelers can feel like artists and develop more creative designs.

3D Printing Application Areas in Jewelry

3D printing jewelry applications can be used in many different areas. Jewelry such as rings, bracelets, necklaces and earrings can be produced with high precision with 3D printing jewelry technology. Designs are shaped in a digital environment and can be printed quickly.

Prototype Production: Producing prototypes for new designs becomes much faster and more efficient with the 3D printing jewelry sector. In this way, information about the final state of the design can be obtained and tests can be made before production.

Personal and Special Designs: Customer-specific designs can be easily produced with 3D printing jewelry applications. Products such as rings with names, jewelry with dates and personalized patterns can be created.

Complex Structures: Complex designs jewelry production with 3d printer are difficult to produce with traditional methods can be easily made with 3D printing technology in jewelry. Especially fine details and sharp lines can be processed more precisely.

[widget-136]

Provide a Competitive Advantage with 3D Printing in Jewelry

3D printing in jewelry is an excellent opportunity to modernize production processes in the sector and provide great advantages to brands. The 3D printing jewelry sector offers personalized, fast and low-cost production opportunities. Jewelry applications with 3D printers provide jewelers with more innovative, creative and efficient production processes, allowing faster and more accurate responses to customer demands.

If you are operating in the jewelry sector, you can carry your business to the future with jewelry production with 3D printing and increase your competitive advantage in the sector. By investing in new technologies, you can offer unique designs to your customers and make yourself different in the sector. We are here to offer you special solutions in the 3D printing jewelry sector!