- Konu Başlıkları

- Rapid Prototyping Cost: Pricing in Modern Design Processes

- How are Rapid Prototyping Costs Determined?

- Factors Affecting Rapid Prototyping Cost

- Technology Selection: Differences Between SLA, SLS and FDM

- Material Type: Differences Between Plastic, Resin and Metal

- Production Volume: Economy of Scale in Costs

- Prototype Complexity: The Impact of Design

- How Much Does Rapid Prototyping Cost?

- Ways to Reduce Rapid Prototyping Cost

Rapid Prototyping Cost: Pricing in Modern Design Processes

Rapid prototyping cost has become an important factor in modern product development processes. This technology, which is used at every stage from product design to production, provides both time savings and cost efficiency. However, costs in the rapid prototyping process may vary depending on the technology used, material type and production volume. In this article, we discuss the factors affecting rapid prototype cost and pricing in detail.

[widget-131]

How are Rapid Prototyping Costs Determined?

Rapid prototyping is a production technology that allows designs to be converted into physical models in a short time. The rapid prototyping cost used in this process is shaped by various factors. In particular, the type of material, the selected printing technology and the complexity of the prototype directly affect the cost.

Factors Affecting Rapid Prototyping Cost

Rapid prototype cost is affected by many factors and these factors play an important role in determining the total budget of the project. Here are the factors that have the most impact on cost:

Technology Selection: Differences Between SLA, SLS and FDM

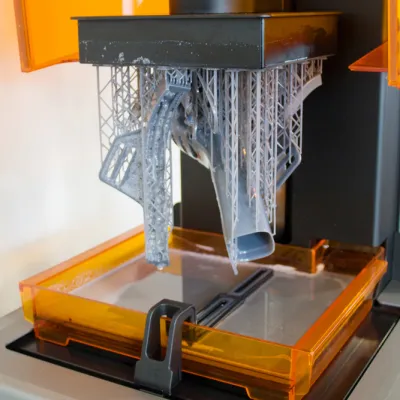

Rapid prototyping costs vary greatly depending on the printing technology used. Technologies such as SLA (Stereolithography), SLS (Selective Laser Sintering) and FDM (Fused Deposition Modeling) offer different application areas and price ranges. For example, SLA technology is preferred in projects requiring high precision, while FDM offers a more economical solution. SLS is ideal for durable and complex prototypes, but its cost may be higher than other technologies.

SLA: Provides detailed and smooth surfaces, but it is costly in terms of material and production time.

FDM: An economical option and suitable for simple prototypes.

SLS: Provides an ideal solution for durable and functional prototypes, but its price is high.

For this reason, it is important to choose the technology that best suits the needs of the project when determining the rapid prototype cost.

Material Type: Differences Between Plastic, Resin and Metal

Rapid prototyping costs vary greatly depending on the material selected. Materials such as plastic, resin and metal affect the durability and functionality of the prototype as well as the costs. For example, plastic materials are generally more affordable and ideal for visual prototypes. Resin is preferred in projects that require high precision, while metal materials are used in applications that require durability and heat resistance.

Plastic: Suitable for economical and lightweight projects.

Resin: Used in projects that require complex details and visual precision.

Metal: Rapid prototype cost is high as it is preferred for functional and durable prototypes.

Choosing the right material provides balance in terms of rapid prototyping price and optimizes the budget of the project.

Production Volume: Economy of Scale in Costs

Production volume is a factor that directly affects the rapid prototyping fee. While the cost per unit may be higher in small-scale production, this cost decreases significantly in large-scale production. Since material and labor costs are distributed, significant savings can be achieved in unit costs, especially in mass production processes.

Low Volume Production: When the number of prototypes is low, the rapid prototype cost per unit increases.

High Volume Production: Rapid prototyping cost decreases when more prototypes are produced.

Determining a production volume that suits your project's requirements will help you find a suitable answer to the question of how much does rapid prototyping cost.

Prototype Complexity: The Impact of Design

The complexity of the prototype has a great impact on the cost of rapid prototyping. Designs with complex geometries require more printing time and materials. This increases energy and labor costs. Simpler designs, on the other hand, offer a more economical solution by reducing costs.

Complex Geometries: Designs with a lot of detail require longer printing times.

Simple Designs: Designs with fewer details minimize costs.

Optimizing complexity during the design phase can provide advantages in terms of both rapid prototyping price and production time.

How Much Does Rapid Prototyping Cost?

The question of how much does rapid prototyping cost? is frequently asked by many designers and manufacturers. This cost varies depending on the details of the project. The main factors taken into consideration when determining the rapid prototyping price are:

Print Time: Longer prints, energy and labor increase the rapid prototyping fee.

Additional Processes: Additional processes such as cleaning, assembly or painting can increase the cost.

[widget-136]

Ways to Reduce Rapid Prototyping Cost

In product development processes, cost is a factor that directly affects the success of the project. Rapid prototyping provides great advantages in terms of cost, on-time delivery, rapid product testing and rapid entry to the market. If you are looking for an economical and efficient solution for your projects, you should learn more about rapid prototyping costs and advantages. With the innovative rapid prototyping solutions offered by Erlas, you can optimize your projects and take your design processes to the next level.