- Konu Başlıkları

- 3D Printing in the Space and Aviation Sector: Break the Boundaries in Technology!

- Use of 3D Printing in the Space and Aviation Sector

- Advantages of 3D Printing in Space and Aviation

- Areas of Use of 3D Printing in the Space and Aviation Sector

- 3D Printing in Spacecraft: Lightweight and Durable Structures

- 3D Printing in Aircraft Parts: Customized and Complex Solutions

- Using 3D Printers in Prototype Production: Fast and Precise Solutions

- 3D Printing for Spare Parts: Emergency Production Solutions

- 3D Printing in the Space and Aviation Sector: Technology Advantages That Shape the Future

- 3D Printing Advantages in Aerospace and Aviation with Erlas!

3D Printing in the Space and Aviation Sector: Break the Boundaries in Technology!

Today, 3D printing in the space and aviation sector offers revolutionary solutions at the point where technology and innovation meet. 3D printer usage in space and aviation, which has a wide range of uses from space vehicles to aircraft components, makes a difference in the sector by significantly reducing both costs and production times. The advantages of 3D printing in space and aviation allow complex parts that are difficult to produce with traditional methods to be easily produced, while also increasing the design freedom of engineers.

[widget-131]

Use of 3D Printing in the Space and Aviation Sector

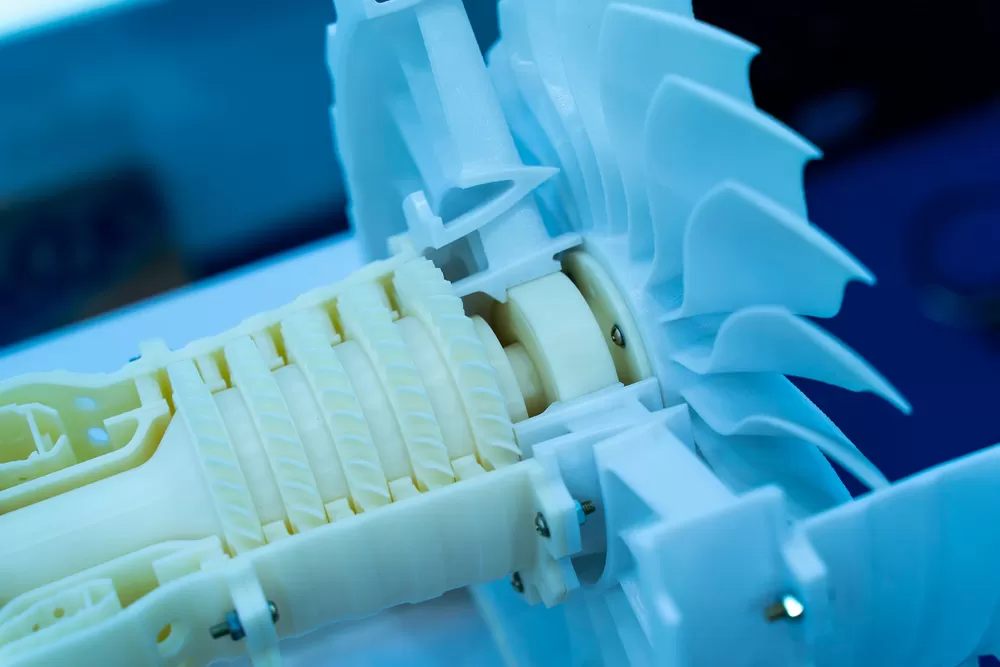

3D printing in the space and aviation sector is a production process that converts digital designs into physical parts with additive manufacturing technology. This technology increases the performance of space vehicles and aircraft by enabling the creation of lightweight, durable and complex structures. The use of 3D printers in space and aviation offers unique advantages in design and production processes. 3D printing advantages in space and aviation:

Fast production of complex and lightweight parts.

Lower costs compared to traditional methods.

The use of 3D printers in space and aviation offers innovative material options that increase part performance.

Advantages of 3D Printing in Space and Aviation

The advantages of 3D printing in space and aviation offer innovative solutions while optimizing production processes. Thanks to 3D printing in aviation, production time is shortened, costs are reduced and performance is increased. 3D printing advantages in space and aviation:

1. Lightweight and Durable Parts

3D printing in the space and aviation sector allows the production of parts that provide high durability with lightweight materials. Fuel savings are achieved and performance is increased by reducing the weight of aircraft and space vehicles.

2. Cost Savings

The advantages of 3D printing in space and aviation significantly reduce the high costs of traditional methods. Printing parts in a single pass reduces waste in assembly and material use.

3. Production of Complex Designs

The use of 3D printers in space and aviation allows complex geometries to be easily produced. This makes it possible to realize more aerodynamic designs and innovative structures.

4. Low Production Time

3D printing and aviation significantly shorten part production times. This enables faster completion of projects and reduced time to market.

5. Sustainability

3D printing technology offers an environmentally friendly production process by using only the materials needed. Preventing waste and saving energy make this technology more sustainable.

Areas of Use of 3D Printing in the Space and Aviation Sector

In the space and aviation sector, 3D printing offers a wide range of applications in production processes. This technology provides innovative solutions in many areas from spacecraft to aircraft parts. Here are the main areas of use of this technology:

3D Printing in Spacecraft: Lightweight and Durable Structures

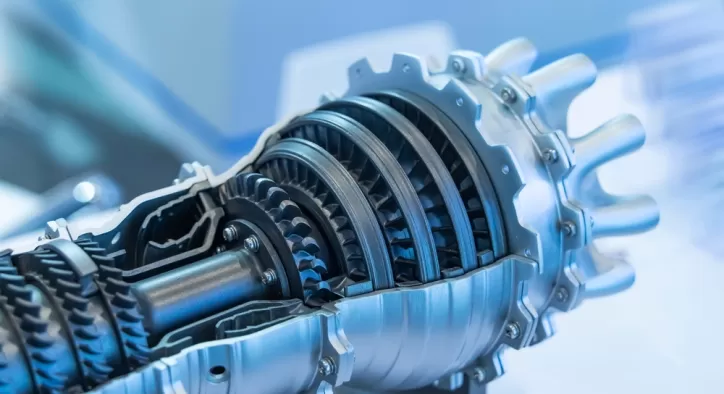

In the space and aviation sector, 3D printing is used to produce lightweight and durable structures, especially for rocket engine parts, satellite components and other spacecraft. This technology is an ideal solution for reducing the weight of spacecraft, providing fuel economy and increasing performance.

Rocket Engines: Thanks to 3D printing, complex and high-temperature resistant parts can be produced for rocket engines.

Satellite Components: Lightweight but durable components increase the reliability of space missions.

Space Missions: 3D printing and aviation meet the need for spare parts in long-term missions by offering on-site production.

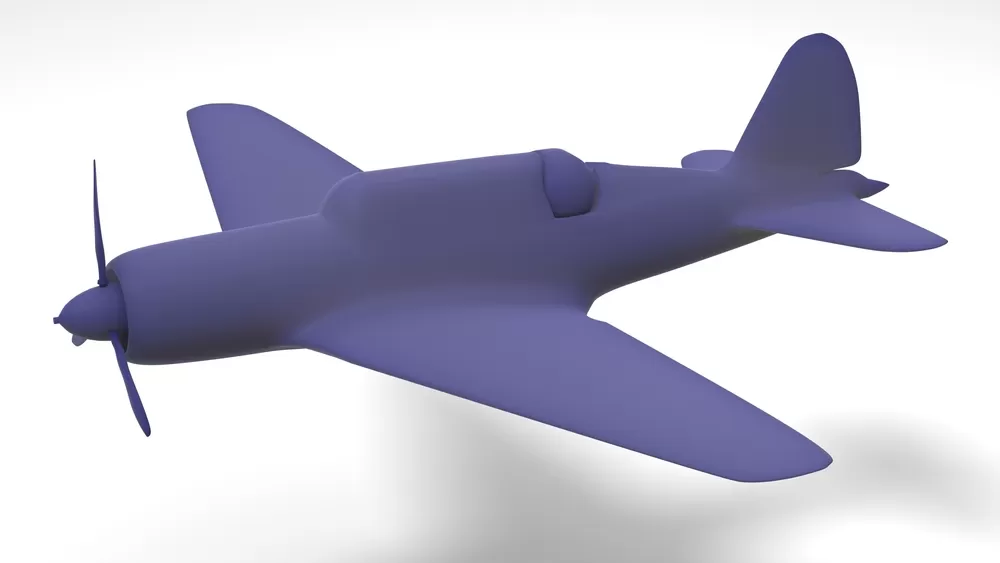

3D Printing in Aircraft Parts: Customized and Complex Solutions

Among the advantages of 3D printing in the space and aviation is the manufacturing of aircraft parts. 3D printing in space and aviation is frequently used in the production of critical parts such as aircraft fuselages, engine components and aerodynamic structures. Suitable for the production of complex and customized parts, this technology reduces production times and costs. 3D printing advantages in space and aviation:

Aerodynamic Parts: Aerodynamic designs that provide less resistance can be created.

Engine Components: Thanks to the advantages of 3D printing in space and aviation, parts that are resistant to high temperatures and pressures increase flight safety.

Mission Customization: Special components needed for aircraft can be produced quickly.

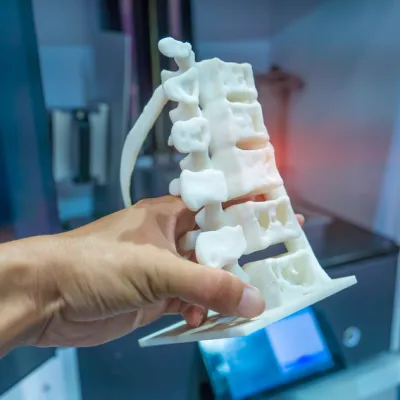

Using 3D Printers in Prototype Production: Fast and Precise Solutions

The use of 3D printers in the space and aviation enables rapid prototyping of new designs. This process allows engineers to test and optimize their designs in the early stages. This ensures production with fewer errors.

Rapid Prototyping: Designs can be converted into physical models in a short time and tested.

Design Optimization: Engineers can quickly make changes to their prototypes.

Cost Savings: Using 3D printers in space and aviation provides both time and cost advantages by preventing faulty production.

3D Printing for Spare Parts: Emergency Production Solutions

3D printing and aviation offer a fast and practical solution to meet spare part needs. Especially in situations that require on-site production, such as space missions, urgent needs can be met quickly thanks to 3D printers.

Production in Space Missions: Spare part needs can be met instantly with on-site printing.

Fast Production: Using 3D printers in space and aviation, parts required in emergency situations can be produced in minimum time.

Reducing Stocking Requirements: Printing can be done immediately

3D Printing in the Space and Aviation Sector: Technology Advantages That Shape the Future

The advantages of 3D printing in aerospace and aviation revolutionize production processes and provide great benefits in terms of both design and functionality. With the innovative 3D printing solutions offered by Erlas, you can accelerate your projects and achieve more effective results.

3D printing in the aerospace and aviation sector will have an even wider area of use in the future. Especially developments in sustainability and cost effectiveness will increase the importance of this technology in the sector. Thanks to 3D printer usage in space and aviation, it will be possible to produce lighter, more durable and more complex structures.

[widget-136]

3D Printing Advantages in Aerospace and Aviation with Erlas!

As Erlas, we offer pioneering solutions in 3D printing technology in the aerospace and aviation sector. We accelerate your projects and optimize costs with our 3D printing solutions tailored to your needs for lightweight, durable and innovative designs. We are ready to make a difference in modern aerospace and space projects with our high-precision production techniques that meet the requirements of the sector. Discover this technology that shapes the future with us and achieve your next big success with us.