- Konu Başlıkları

- 3D Prototype in Defense Industry: Areas of Use and Technological Solutions

- 3D Prototyping Method in Defense Industry

- Areas of Use of 3D Prototypes in the Defense Industry

- 1. Weapon Systems: Faster and Precise Production

- 2. Military Vehicle Parts: Ideal Solution for Complex Designs

- 3. Aviation and Space Technologies: Innovative and Reliable Solutions

- 4. Drone and Unmanned Systems: Support for Future Technology

- 5. Electronic Systems and Sensors: Precision Production and Testing

- 4 Prominent Advantages of 3D Prototyping in the Defense Industry

- 1. Production in Shorter Times with Rapid Prototyping

- 2. More Economical Solutions with Cost Savings

- 3. Creative Solutions with Design Flexibility

- 4. Lightweight and Durable Parts

- 3D Prototype Solutions in the Defense Industry with Erlas

3D Prototype in Defense Industry: Areas of Use and Technological Solutions

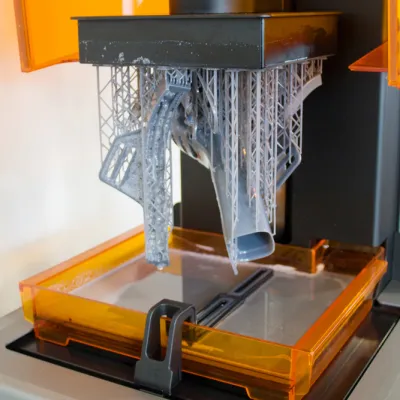

3D prototype in defense industry stands out as a production method that is born from the combination of modern technologies and brings revolutionary innovations to the sector. Offering speed, cost effectiveness and design flexibility compared to traditional production methods, this technology provides unique solutions especially in critical areas such as the defense industry. 3d prototyping in defense industry in the defense industry offers an ideal option for rapid prototype production, realization of complex designs and low-volume production.

[widget-131]

3D Prototyping Method in Defense Industry

3D prototype in defense industry refers to the conversion of digital designs into physical models via three-dimensional printers. This process provides a wide range of advantages from producing prototypes of complex parts used in defense projects to testing and optimizing production processes.

Prominent features of 3D prototyping in the defense industry:

Rapid prototype production.

Implementation of detailed and complex designs.

Cost savings compared to traditional production processes.

Areas of Use of 3D Prototypes in the Defense Industry

3D prototype in defense industry provide a wide range of innovative solutions and provide fast and effective responses to critical needs in the sector. In the defense industry, 3D prototyping is used in many areas, from the implementation of detailed designs to testing and optimizing production processes. Here are the prominent areas of use of 3D prototyping in defense industry technology:

1. Weapon Systems: Faster and Precise Production

In the defense industry, the use of 3D prototypes allows the rapid production of prototypes of weapon systems. This technology plays a major role in the design, testing and development stages of parts used in weapon systems.

Precise Prototypes: Weapon parts with complex geometries can be produced with high precision with 3D prototype production.

Rapid Testing and Improvement: Produced prototypes can be tested quickly and design processes can be optimized.

Low-Cost Production: 3D prototyping in the defense industry requires less material and labor compared to traditional methods.

2. Military Vehicle Parts: Ideal Solution for Complex Designs

3D prototype in defense industry technology is used to produce special parts for tanks, armored vehicles and other military vehicles. In particular, the complex components of these vehicles can be easily designed and produced.

Production of Complex Parts: Detailed parts that are difficult to produce with traditional methods become possible with 3D prototype production.

Customized Solutions: It is possible to easily design special parts for different vehicles.

Lightweight and Durable Materials: Lightweight and durable parts that will increase vehicle performance can be produced.

3. Aviation and Space Technologies: Innovative and Reliable Solutions

In the defense industry, 3D prototyping is widely used in the production of critical components in aviation and space projects. Both prototype and final parts for aircraft and space vehicles are produced with high precision with this technology.

Lightweight and Durable Parts: Production of lightweight but strong parts for use in aviation.

Aerodynamic Designs: Easy modeling of complex aerodynamic structures.

Rapid Prototyping: Provides early testing opportunity in aircraft and space vehicle projects.

4. Drone and Unmanned Systems: Support for Future Technology

In modern defense systems such as drones and unmanned vehicles, 3D prototype production in the defense industry offers rapid development and testing processes. Special components for these vehicles and the use of 3D printers in the defense industry can be easily produced.

Detailed Part Production: Complex components used in drones and unmanned systems can be produced with 3d printer in defense industry.

Rapid Prototype Development: New designs can be tested and improved quickly.

Cost Efficiency: The use of 3D printers in the defense industry offers economical solutions with low production costs.

5. Electronic Systems and Sensors: Precision Production and Testing

The use of 3d prototype production in the defense industry also provides a great advantage in the production of electronic circuits and sensors. Prototypes of electronic systems can be produced quickly and subjected to performance and durability tests.

Precision Components: Detailed production of electronic circuits and sensors.

Efficiency in Testing Processes: 3D prototyping in the defense industry can be prepared quickly for performance testing.

Customization: Project-specific electronic components can be produced.

The use of 3D prototypes in the defense industry provides effective, fast and innovative solutions to meet critical needs in the sector. 3D prototype production technology has an important place in the future of the defense industry with its features such as cost advantages, design flexibility and speed.

4 Prominent Advantages of 3D Prototyping in the Defense Industry

The use of 3D prototypes in the defense industry provides many advantages to the sector. This technology, which stands out with its speed, flexibility and cost savings compared to traditional production methods, offers innovative solutions.

1. Production in Shorter Times with Rapid Prototyping

3D prototyping in the defense industry allows the design to be quickly converted into a physical model. This prevents loss of time in critical projects and allows rapid results.

Time Saving: 3D prototype in defense industry processes that may take weeks can be completed in hours.

Early Testing Opportunity: Thanks to 3D printers in the defense industry, designs can be tested quickly and necessary adjustments can be made.

Efficiency in Project Management: More prototype production in a shorter time.

2. More Economical Solutions with Cost Savings

The use of 3D prototypes in the defense industry significantly reduces production costs by saving material and labor.

Low Material Waste: Only the required material is used.

Reduction of Mold Expenses: Production in one go eliminates the need for expensive mold processes.

Optimized Production Processes: More 3D prototype production opportunity with fewer resources.

3. Creative Solutions with Design Flexibility

3D printer technology in the defense industry allows complex and original designs to be easily produced.

Production of Complex Parts: Challenging geometries and details are easily realized.

Customized Solutions: Rapid production of prototypes specific to projects is possible.

Innovative Designs: 3D prototype production Solutions that are not possible with traditional methods can be produced.

4. Lightweight and Durable Parts

3D prototype in defense industry production enables production with lightweight but durable materials used in defense projects. This offers ease of transportation and long-lasting use.

Increased Performance: Lighter parts positively affect performance.

Long-Lasting Use: 3D prototype usage in defense industry system extends the life of projects with durable materials.

[widget-136]

3D Prototype Solutions in the Defense Industry with Erlas

3D prototypes will become more widespread in the defense industry in the future and will play a critical role in innovative projects. With more sustainable material options and advanced production methods, this 3d printer in defense industry technology will radically change the dynamics of the defense industry.

As Erlas, we add speed, flexibility and efficiency to your projects with our 3D prototype solutions in the defense industry. With our high-precision printers and expert team, we make a difference in the sector by meeting the needs of your projects in the best way. As your solution partner in modern defense technologies, let's build the projects of the future together!