- Konu Başlıkları

- Architectural Model Printing with 3D SLA Machines: A New Era in Architecture

- Using Architectural Printing with 3D SLA Machines

- How to Print Architectural Models with 3D SLA Machines?

- Digital Modeling: Appropriate Design for 3D SLA Machines

- Printing Process: Layer-by-Layer Production with SLA Machines

- Final Process: Completion and Detailing of the Model

- Advantages of 3D SLA Architectural Model Printing

- The Importance of Architectural Model Printing Process with 3D SLA Machines

- Application Areas of 3D SLA Architectural Model Printing

- The Future of Architectural Model Printing with 3D SLA Machines

- Creativity and Precision: The Role of 3D SLA Printing in Architecture

Architectural Model Printing with 3D SLA Machines: A New Era in Architecture

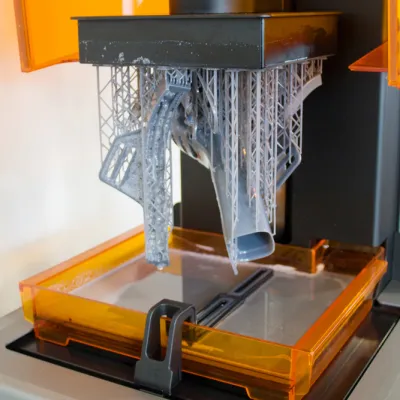

Today, the power of technology in the architecture sector is radically changing design processes. Architectural model printing with 3D SLA machines is an innovative method that allows designs to be converted into physical models quickly and in detail. With its precision, material flexibility and time-saving features, 3D SLA architectural model printing has become a prominent technology in modern architecture projects.

[widget-131]

Using Architectural Printing with 3D SLA Machines

Architectural model printing with 3D SLA machines is the process of creating designs in layers using Stereolithography (SLA) technology. SLA machines convert liquid resin into a solid model using laser technology that works with high precision. This method, which is used especially for complex and detailed designs, greatly accelerates 3D architectural printing processes in architecture.

Reasons why SLA machines are preferred in architecture projects:

It produces even small-scale details clearly by offering high resolution.

It allows even complex geometries to be easily modeled.

It creates different textures and appearances with various materials.

How to Print Architectural Models with 3D SLA Machines?

Architectural model printing with 3D SLA machines is a multi-stage process that allows the production of precise and detailed models. We can better understand this process by examining the details of each stage.

Digital Modeling: Appropriate Design for 3D SLA Machines

The first step in the 3D SLA architectural model printing process is to create a model in a digital environment. Architectural projects are designed in detail using CAD (Computer-Aided Design) software. These models are specially optimized for production on SLA machines.

Detailed Design: Complex geometries and details are meticulously created in CAD software.

Adaptation to SLA: The digital model is converted to a readable file format (e.g. STL format) by the SLA machine.

Error Control: Deficiencies and errors in the digital model are corrected to prevent printing errors.

Correct digital modeling for 3D architectural printing is the basis of a quality print.

Printing Process: Layer-by-Layer Production with SLA Machines

The most important step in the 3D SLA architectural model printing process is the physical production of the model by the SLA machine. In this process, the liquid resin is hardened layer by layer with the help of a laser.

Additive Production: SLA machines create each layer of the digital model by laser processing it onto the resin surface.

Precision and Smoothness: This technology provides smooth and high-resolution surfaces. This is a critical advantage especially in architectural model printing processes with 3D SLA machines.

Material Usage: In 3D architectural model printing, resin types are selected according to the needs of the model. For example, transparent resins or flexible materials can be used.

This step allows the 3D SLA architectural printing technology to offer impressive results with its precision.

Final Process: Completion and Detailing of the Model

After the printing process is completed, some final processes are performed on the model. The final process in the architectural model printing process with 3D SLA machines aims to improve the model in terms of aesthetics and functionality.

Cleaning: The model is cleaned by removing resin residues. This process allows the details to emerge more clearly.

Coating and Painting: If necessary, a protective coating is applied to the model or an aesthetic appearance is achieved by painting it.

Assembly: In larger projects, the assembly of multiple parts is completed.

These steps ensure that the 3D architectural model printing process is completed and the model is ready for presentation.

Advantages of 3D SLA Architectural Model Printing

3D SLA architectural model printing offers many advantages to both the design and production processes in architectural projects. Compared to traditional methods, 3D architectural model printing offers faster, more precise and cost-effective solutions.

Precision and Detail:

SLA machines make 3D SLA architectural model printing processes flawless with their ability to reflect even the smallest details. They are indispensable in the production of complex architectural details.

Time and Cost Savings:

Architectural model printing with 3D SLA machines offers fast production opportunities and shortens the delivery time of projects. This is a great advantage especially for projects with tight timelines.

Design Flexibility:

3D architectural printing provides aesthetics and functionality in projects by offering the flexibility to work with different materials. Various modeling options are possible with transparent, durable or flexible materials.

Sustainability:

3D SLA architectural model printing processes reduce waste, use only the material needed and provide an environmentally friendly production.

The Importance of Architectural Model Printing Process with 3D SLA Machines

Each step enables 3D SLA architectural model printing technology to provide precise, impressive and practical solutions in projects. Accurate digital modeling, precise printing process and detailed finishing ensure the creation of high-quality architectural models. This process contributes to the more effective implementation of architectural projects.

Application Areas of 3D SLA Architectural Model Printing

3D SLA architectural model printing offers creative solutions in different projects. This technology is frequently used in the following areas:

Architectural Model Production: Thanks to 3D architectural model printing, detailed models can be prepared quickly and flawlessly.

Building Elements: It is used to produce prototypes of components such as columns, beams and decorative elements.

Presentation Models: It allows impressive presentation of projects with 3D architectural model printing.

The Future of Architectural Model Printing with 3D SLA Machines

3D SLA architectural model printing plays an important role in the future of the architectural sector. The increasing use of sustainable materials and the production of more durable and lightweight models increase the potential of this technology. In the future, it is anticipated that 3D architectural printing methods will be used directly in construction projects.

[widget-136]

Creativity and Precision: The Role of 3D SLA Printing in Architecture

If you are looking for detail, speed and flexibility in your projects, architectural model printing with 3D SLA machines is the ideal solution for you. This technology we use stands out as a creative and practical tool in modern architectural projects. As Erlas, you can take your projects to the next level with the innovative 3D SLA solutions we offer.