- Konu Başlıkları

- SLA Use in the Automotive Sector

- What is SLA 3D Printing Technology?

- Automotive Sector 3D Printing Usage Areas

- Prototype Production

- Special Part Production

- Ergonomics and Design Tests

- Research and Development (R&D)

- What are the Advantages of SLA 3D Printing in the Automotive Sector?

- SLA 3D Printing Technology is Very Valuable in Automotive!

SLA Use in the Automotive Sector

The automotive sector has always been a pioneer of industrial development with its demand for innovative technologies and production methods. In this sector, SLA 3D printing technology has been used in various areas from design to prototyping, accelerating production processes and reducing costs. It has become an indispensable part of SLA 3D printing applications in the automotive sector, especially in the production of delicate and detailed parts. By leveraging SLA 3D printing in the automotive sector, manufacturers can produce prototypes and custom parts faster and more efficiently than ever before.

[widget-131]

What is SLA 3D Printing Technology?

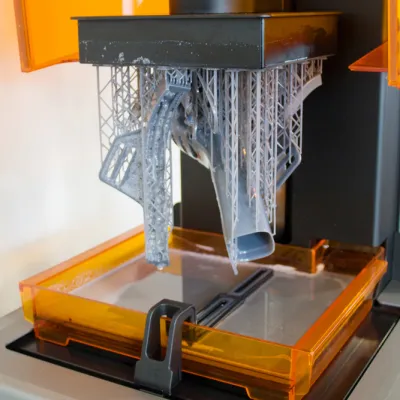

SLA (Stereo Lithography Apparatus) is a 3D printing technology that uses photopolymerization for shaping. This method works by hardening a liquid photopolymer material layer by layer with a laser. It can work with materials of different hardness and transparency. SLA use in the automotive sector has become indispensable for producing prototypes, custom parts, and intricate designs with unmatched precision. It offers smoother and more professional surfaces than traditional 3D printing methods. It can make precise prints down to millimetric details. These features create an ideal basis for the use of SLA in the automotive sector.

Automotive Sector 3D Printing Usage Areas

With developing material science and printing technologies, the use of SLA in the automotive sector is becoming increasingly widespread. The increase in demand for electric and autonomous vehicles in the automotive sector indicates that SLA 3D printing will be used more, especially in the production of special parts and sensor housings. Today, SLA 3D printing is actively used in the automotive sector in the following areas:

Prototype Production

In the automotive sector, SLA 3D printing is used intensively in the prototype creation phase for the design of a new vehicle. It allows detailed testing of both external parts and internal mechanisms.

For example: The "vent panel" prototype you use in vehicles is produced with SLA technology. This method offers the opportunity to foresee possible problems in the design of the panel and to make the necessary corrections quickly. So automotive sector 3d printing saves both time and money.

Special Part Production

SLA usage and 3D printing technology are frequently preferred in the automotive sector in the design and production of small-scale special parts. This method provides great convenience, especially in the production of retro or rare automobile parts.The growing SLA use in the automotive sector supports faster production cycles, reduces costs, and enhances the overall quality of vehicle components.

Ergonomics and Design Tests

3D printing SLA technology in the automotive sector offers a fast and effective solution for testing vehicle interior designs and ergonomic details. This technology is used in areas such as steering wheels, gear levers or seat components.

Research and Development (R&D)

R&D units of automotive companies make extensive use of 3D printing technologies in the automotive sector while developing innovative products.

What are the Advantages of SLA 3D Printing in the Automotive Sector?

SLA 3D printing in the automotive sector stands out especially in the production of parts that require precision. SLA technology allows designers and engineers to easily produce parts with complex geometry. The one-to-one creation of details in the interior and exterior designs of the vehicle is also one of the important advantages offered by SLA 3D printing technology in the automotive sector.

Of course, the advantages of using SLA in the automotive sector are not limited to this. 3D printing in the automotive sector significantly shortens the production time of prototypes and special production parts. A prototype that would take weeks with traditional production methods can be ready in days with SLA technology. Automotive sector 3d printing both saves time and accelerates the launch of new products.

Another advantage of SLA 3D printing in the automotive sector is cost. Using SLA in the automotive sector reduces mold costs and raw material waste. It offers a particularly economical solution for one-time production. Therefore, it is much more cost-effective for prototypes or special designs to be produced in small numbers. Parts with very complex geometries can be easily realized with SLA 3D printing technology. Designs that cannot be produced with traditional methods can be implemented without any problems thanks to this technology.

[widget-136]

SLA 3D Printing Technology is Very Valuable in Automotive!

3D printing in the automotive sector has created a significant revolution in the sector by offering both time, cost and quality advantages. Especially in the automotive sector, the use of SLA offers an indispensable solution for designers and engineers who care about details. You too can optimize your production processes and become a pioneer in the future production world by using SLA 3D printing technology in the automotive sector through Erlas Global. Remember; more durable, lightweight and environmentally friendly materials indicate that future applications of this technology will spread to much younger business areas. SLA 3D printing in the automotive sector not only reduces production costs but also accelerates the time-to-market for innovative vehicle designs.