- Konu Başlıkları

- How Do Industrial 3D Printing Machines Work?

- What are the Advantages of Industrial SLA Printers?

- Where Are Industrial SLA Printers Used?

- Important

- Limitations of Industrial SLA Machines

- Erlas Global for Industrial Stereolithography SLA 3D Printer Printing Products!

How Do Industrial 3D Printing Machines Work?

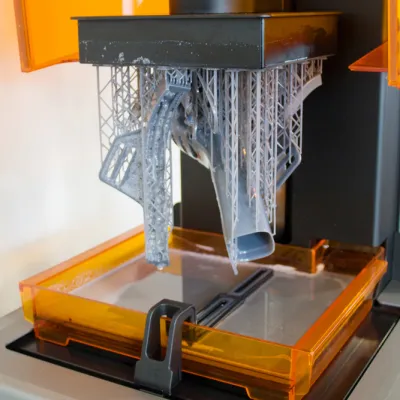

Industrial SLA machines, or industrial SLA printers, are machines that use stereolithography printing technologies to produce high-precision, finely detailed industrial parts. An industrial SLA printer works by curing a liquid photopolymer resin layer by layer with laser light, resulting in durable, high-quality industrial 3D printing. Industrial 3D printers can serve different sectors with SLA printers.

[widget-130]

What are the Advantages of Industrial SLA Printers?

Industrial SLA printers are called state-of-the-art 3D printing methods used in large-scale part production. Since industrial SLA machines produce thinner layers compared to other 3D printing methods, they process parts with fine details in the best way. Therefore, a wide variety of productions can be made in different sectors with the industrial SLA 3D printer.

Industrial SLA printer machines make smoother productions compared to other printing methods that require sanding. Industrial 3D printing machines are used if there is no need for surface treatments and better results are desired in a shorter time. Industrial SLA 3D printer machines give near-perfect results in hollow structures, thin walls and small details. Even the most precisely produced dental prostheses are made by industrial SLA machines. Industrial 3D printers also allow for material diversity; industrial SLA printers that can work with photopolymer resins with different properties can perform rapid prototyping and shorten the product development cycle.

Where Are Industrial SLA Printers Used?

Industrial SLA printers are used in the automotive industry to produce electronic enclosures, interior design prototypes, air ducts and engine components; in medicine and dentistry to produce precision prosthetics, dental molds, anatomical models and customized products; in the aerospace industry for rapid prototyping of aircraft and satellite components; in the architecture and design industry to produce models of buildings, city plans and structures; in the electronics and manufacturing industry with circuit boards, buttons and mechanical parts.

Industrial SLA 3D printer machines test small electronic components, speed up production phases and produce high-resolution models and prototypes. It enables the concretization and visualization of designs with 3D printing. It can produce small volumes at low cost, prototyping of complex and small components is done quickly and precisely. Components that require durability and heat resistance can be produced with SLA.

Important

SLA printers can typically produce layers as thin as 25-100 microns.

Limitations of Industrial SLA Machines

Parts produced with an industrial SLA 3D printer may be less durable than parts produced with FDM or SLS technologies. Resin-based materials may break under mechanical stress. Production speeds vary depending on the complexity of the part and the material used, but industrial SLA printer machines can be slower than technologies such as FDM. Industrial 3D printers may need post-process cleaning or surface smoothing.

[widget-137]

Erlas Global for Industrial Stereolithography SLA 3D Printer Printing Products!

As Erlas Global, we make fast, precise and efficient production with industrial SLA printers in a wide range of fields from automotive to aviation, from aerospace industry to wood design, from consumer accessories to energy sector. With our expert technical staff, we make the necessary measurements, plans and projects; then we make industrial 3D printing in accordance with your requirements and expectations. You can contact Erlas Global for your small or large-scale productions with precise details. Make detailed prototyping and quality production with an industrial SLA 3D printer.