- Konu Başlıkları

- Costs are Decreasing and Speed is Increasing in Industrial Production!

- What is an Industrial Prototype?

- The Role of 3D Printing in Industrial Prototype Production

- Advantages of Industrial Prototype Production

- Industrial Prototype Production in Different Sectors

- 1. Prototype in the Automotive Industry

- 2. Prototype in the Food Industry

- 3. Prototype in the Electrical Industry

- 4. Prototype in the Military Industry

- The Future of Industrial Prototype Production

- You Can Work with Erlas Global for Industrial Prototype Manufacturing

Costs are Decreasing and Speed is Increasing in Industrial Production!

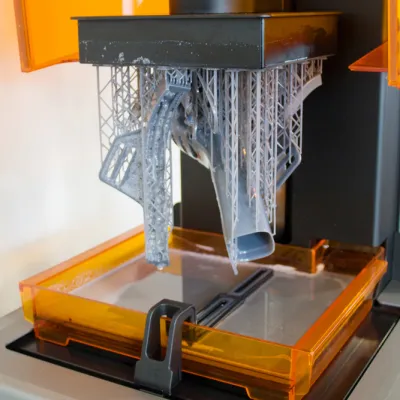

Industrial prototype manufacturing has become one of the cornerstones of modern production processes. Developing technologies and especially the use of 3D printing methods have made industrial prototype manufacturing faster, more flexible and cost-effective. 3D prototype manufacturing in the industry plays a critical role in accelerating the design and development stages in many sectors. So, what are the important points in industrial prototype manufacturing?

[widget-131]

What is an Industrial Prototype?

An industrial prototype is the first example of how a product will actually work and look during the design phase, before production. This prototype allows designers, engineers and manufacturers to test the functionality of the product, see design errors and optimize the production process. In the industry, 3D prototype production offers a faster and lower cost solution that replaces traditional mold and processing methods. 3d prototype in industry technology transforms industrial prototype production into real-time prototyping processes.

The Role of 3D Printing in Industrial Prototype Production

When it comes to industrial prototype production, 3D printing technology is of great importance. This technology allows prototypes to be produced quickly and at low cost. The use of 3D prototypes in the industry is much faster and more flexible than traditional methods. It does not require molds or special equipment to produce prototypes, only digital designs are sufficient. This allows changes to be made in the design to be quickly reflected in the prototype. Industrial prototype manufacturers can thus test their products in a short time, make improvements and move on to the final production process.

Advantages of Industrial Prototype Production

The industrial prototype manufacturing process is much faster than traditional methods. Thanks to 3D printers, designers and engineers can obtain prototypes of their products in days. This rapid prototyping process speeds up the product development phase and shortens the time to market. Other advantages of 3D prototyping in the industry are as follows:

Low Cost: Traditional production methods require expensive molds and machines for prototype production. However, 3D prototype production in the industry can be done with only design files and printers, which provides great cost savings. In addition, the production of prototypes only when needed significantly reduces inventory costs and production times.

Flexibility and Customization: Industrial prototype manufacturing allows changes to be made to the design to be implemented quickly. Every change in the design can be reflected immediately on the prototype. This helps designers to quickly test their ideas and develop the product. It is also possible to use different materials and geometric shapes, so customized prototypes can be produced for each sector.

Testing and Evaluation: Rapid production of prototypes allows the design to be tested functionally. The functionality, durability and ergonomics of the product can be tested, so that problems that may be encountered during the production phase can be detected in advance in industrial prototype manufacturing.

Industrial Prototype Production in Different Sectors

Industrial prototype manufacturing offers various advantages in different sectors. Below, we will examine industrial prototype manufacturing applications in some sectors:

1. Prototype in the Automotive Industry

3d prototype in industry accelerates the design and development processes of vehicles. Prototypes can be produced quickly for new model designs, aerodynamic tests and safety tests. In addition, industrial prototype manufacturing can be used for small-scale production for the production of automotive parts. This provides a great advantage, especially in terms of quickly changing prototypes and creating innovative designs.

2. Prototype in the Food Industry

Prototype production in the food industry can be applied in a wide range from product packaging designs to parts of machines used for production lines. Industrial prototype production can be used to test the aesthetic and functional properties of food packages. In addition, 3d prototype in industry for food processing machines can be produced and tested quickly to increase efficiency.

3. Prototype in the Electrical Industry

In the electrical industry, 3D prototype manufacturing is vital in the industry, especially for new electrical devices, motors, and electronic components. Industrial prototype manufacturing allows for rapid testing of complex components such as circuit boards, electric vehicles, and battery systems. In addition, testing prototypes for durability and functionality offers great advantages to manufacturers.

4. Prototype in the Military Industry

Prototype production in the military industry offers special solutions to the needs of the defense industry. Industrial prototype production enables the creation of fast and reliable prototypes for military vehicles, weapons, security systems and other critical equipment. In other words, thanks to industrial prototype production, security tests and functionality tests of military equipment can be performed faster, thus shortening the production time of high-performance equipment needed in wartime.

The Future of Industrial Prototype Production

Industrial prototype production is a rapidly evolving field. With the development of 3D printers and other production technologies, industrial prototype production will be even faster and will be carried out at lower costs. The integration of new materials and software will allow designers to create more creative and functional prototypes.

As technology advances, 3D prototype production in the industry will become even more widespread and will become an integral part of production processes in many sectors. It is expected that this technology will be used more widely, especially in the automotive, food, electrical and military industries.

[widget-136]

You Can Work with Erlas Global for Industrial Prototype Manufacturing

Industrial prototype manufacturing offers advantages such as fast production, low cost and high customization. 3D prototype manufacturing in the industry accelerates design processes while also making it possible to test the functionality and reliability of products. The use of this technology in the automotive, food, electrical and military sectors will be an important step that will shape the future of industries. If you want to step into the latest technologies in industrial prototype manufacturing, we can offer you special solutions with our professional 3D prototype manufacturing services.