- Konu Başlıkları

- Why Precision Matters in 3D Printer Manufacturing

- Core Components That Impact Precision

- 1. Printer Calibration Systems

- 2. Material Control

- 3. Layer Height and Resolution

- 4. Environmental Conditions

- Erla’s Global: Engineering Precision Into Every Unit

- Technologies Driving Higher Precision in 3D Printing

- AI-Powered Error Detection

- Closed-Loop Feedback Systems

- Hybrid Manufacturing

- Quality Assurance Protocols We Follow

- Case Study: Precision Prototypes for High-Performance Optics

- Custom Orders Designed for Accuracy

- Precision as a Competitive Advantage

- Final Thoughts: Precision Builds Trust, Not Just Parts

- Frequently Asked Questions

- Precision as the Cornerstone of Quality 3D Printing

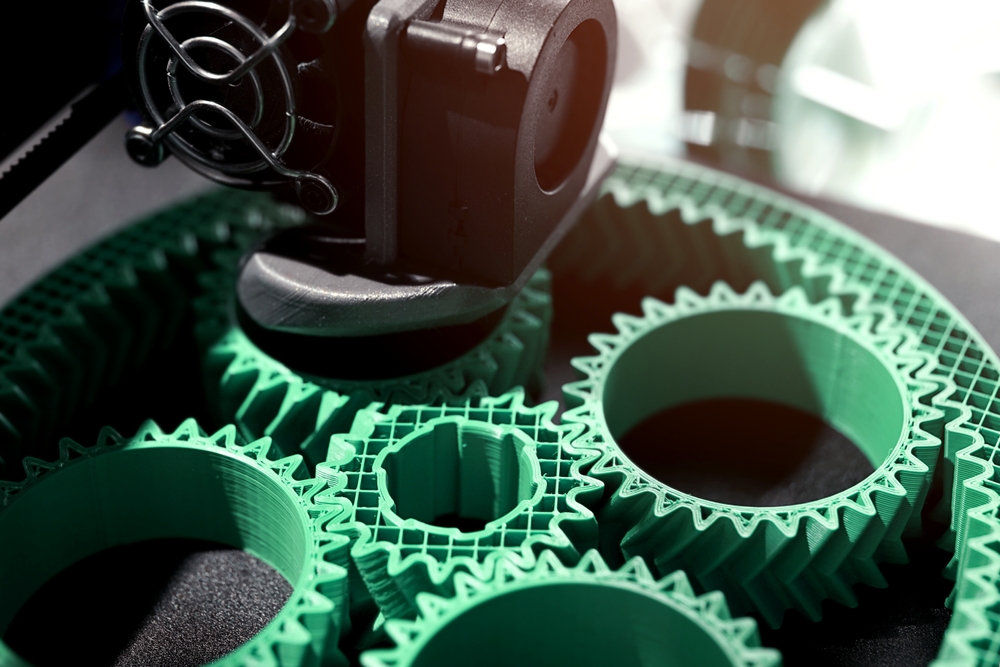

Precision is not just a technical aspiration in 3D printer production—it’s the very standard that defines quality, functionality, and market readiness. As additive manufacturing grows more sophisticated, manufacturers and engineers alike are turning their focus to pinpoint accuracy in every phase of the production pipeline. Whether you’re designing aerospace components, medical devices, or customized tools, achieving micron-level precision is essential to meet industry demands and client expectations.

At Erla’s Global, we believe that precision is more than tolerance control—it's a culture embedded in our processes, technologies, and project execution. This article explores what precision in 3D printer production entails, which technologies ensure accuracy, and how our production standards are helping clients build better products.

[widget-131]

Why Precision Matters in 3D Printer Manufacturing

In traditional manufacturing, errors are often corrected downstream. In additive manufacturing, especially during rapid prototyping or final part production, the precision of the printer defines the final quality. With intricate geometries and performance-critical applications, even minor misalignments can lead to product failure or non-compliance with industry standards.

High precision leads to:

- Enhanced product functionality

- Better material efficiency

- Reduced post-processing

- Greater repeatability across production batches

- Improved customer satisfaction and trust

Core Components That Impact Precision

1. Printer Calibration Systems

Proper calibration ensures that each axis of the printer behaves exactly as programmed. Advanced machines use auto-calibration systems, which rely on sensors and feedback loops to adjust nozzle position, bed alignment, and extrusion settings in real time.

2. Material Control

Material consistency is critical. Filament diameter, resin purity, and powder particle size must meet strict standards to maintain dimensional accuracy throughout a job.

3. Layer Height and Resolution

The thinner each printed layer is, the smoother and more accurate the final part becomes. Precision-focused applications often require layer heights below 50 microns, which can significantly affect production time but drastically improve quality.

4. Environmental Conditions

Even temperature and humidity in the print chamber can impact precision. Controlled enclosures and climate management systems ensure that every layer cures or hardens under optimal conditions.

Erla’s Global: Engineering Precision Into Every Unit

At Erla’s Global, precision starts at the design consultation phase. Our engineering team analyzes the client's requirements and recommends optimal printing methods and materials tailored to the end-use application.

We leverage high-end FDM, SLA, and SLS machines calibrated for industrial use. Our quality control team uses laser scanning and digital metrology tools to verify that every print meets tight tolerances.

As seen in our 3D printing service, our systems are designed for both complex prototype geometries and high-volume production with minimal deviation.

Technologies Driving Higher Precision in 3D Printing

AI-Powered Error Detection

Modern machines employ AI algorithms to detect potential printing issues before they happen. Predictive monitoring of layer adhesion, print head stability, and feed rate enables intervention without stopping the job.

Closed-Loop Feedback Systems

These systems use real-time sensor data to continuously adjust the printing process. Adjustments might include minor changes in temperature, print speed, or material flow, which ultimately enhance print accuracy.

Hybrid Manufacturing

Combining additive and subtractive methods, hybrid manufacturing allows for precision machining after printing. This is especially useful in medical and aerospace applications where absolute dimensional certainty is required.

Quality Assurance Protocols We Follow

At Erla’s Global, precision doesn’t end with the print. Every product goes through multi-stage QA checks:

- First Article Inspection (FAI)

- Dimensional Analysis with Coordinate Measuring Machines (CMM)

- Surface Roughness Measurement

- Fitment Testing (when applicable)

These processes align with standards like ISO 9001:2015, ensuring reliable results across all production batches.

To understand how precision impacts pricing, read our breakdown of the cost of 3D printer production and how various quality levels affect budget planning.

Case Study: Precision Prototypes for High-Performance Optics

A client in the optics industry approached us with a request for custom mounts with less than 0.05 mm deviation tolerance. Using SLA technology, coupled with post-process CNC trimming, we delivered components that not only met tolerance demands but also required zero secondary alignment.

This level of performance convinced the client to shift their full prototyping line to Erla’s Global—a testament to our high-precision capabilities.

Custom Orders Designed for Accuracy

Not all applications require the same level of precision. Our team helps clients define acceptable tolerance thresholds depending on the function, environment, and cost parameters. Whether you need a single highly detailed component or order custom 3D printer prototypes for a larger assembly, we tailor every job with measurable accuracy in mind.

Precision as a Competitive Advantage

In competitive markets, precision sets products apart. Inconsistent tolerances can damage a brand’s reputation, while precision-printed components elevate it. Our team integrates precision metrics into each order proposal, giving clients full clarity on what to expect and how we’ll achieve it.

Final Thoughts: Precision Builds Trust, Not Just Parts

Precision is the invisible foundation of great products. It ensures performance, drives client satisfaction, and minimizes downstream problems. At Erla’s Global, we combine engineering experience, advanced tools, and rigorous quality control to make precision a reliable outcome, not a lucky result.

Frequently Asked Questions

What tolerances are considered "high precision" in 3D printer production?

High precision typically refers to tolerances under ±0.1 mm. At Erla’s Global, we often achieve tolerances as tight as ±0.05 mm depending on the technology and material used.

How does Erla’s Global ensure consistent precision across large batch runs?

We use automated QA tools, digital calibration protocols, and machine learning systems that monitor variance in real time. Each part is measured and validated against our internal benchmarks.

Can I request a precision level based on my product's function?

Absolutely. During the consultation phase, our engineers will help define appropriate tolerance levels based on mechanical loads, assembly needs, and cost factors.

Does precision affect the cost of 3D printer production?

Yes. Higher precision requires advanced machines, slower print speeds, and more quality checks. For a full overview, review our guide on the cost of 3D printer production.

What industries benefit most from high-precision 3D printing?

Sectors such as aerospace, medical devices, optics, automotive, and R&D rely heavily on high-precision prints for their critical applications.

Precision as the Cornerstone of Quality 3D Printing

Precision in 3D printer production is no longer optional—it's the standard that drives differentiation and long-term success. From internal calibration protocols to laser-guided inspection systems, Erla’s Global ensures that every unit shipped reflects not just your design, but your brand’s integrity.