- Konu Başlıkları

- Why Certifications Matter in 3D Printer Manufacturing

- Key Certifications for 3D Printer Production

- 1. ISO Standards

- 2. CE Marking (Conformité Européenne)

- 3. FCC Certification (Federal Communications Commission – USA)

- 4. UL Certification (Underwriters Laboratories)

- Regional and Market-Specific Certifications

- How Certification Affects Production Costs and Planning

- Erla’s Global Approach to Certified Production

- Frequently Asked Questions

- What is the most important certification for entering the EU market?

- Do I need both FCC and CE certifications?

- How long does the certification process usually take?

- Are certifications one-time processes?

- Can startups afford full certification?

- Certification: The Gateway to Global-Ready 3D Printing

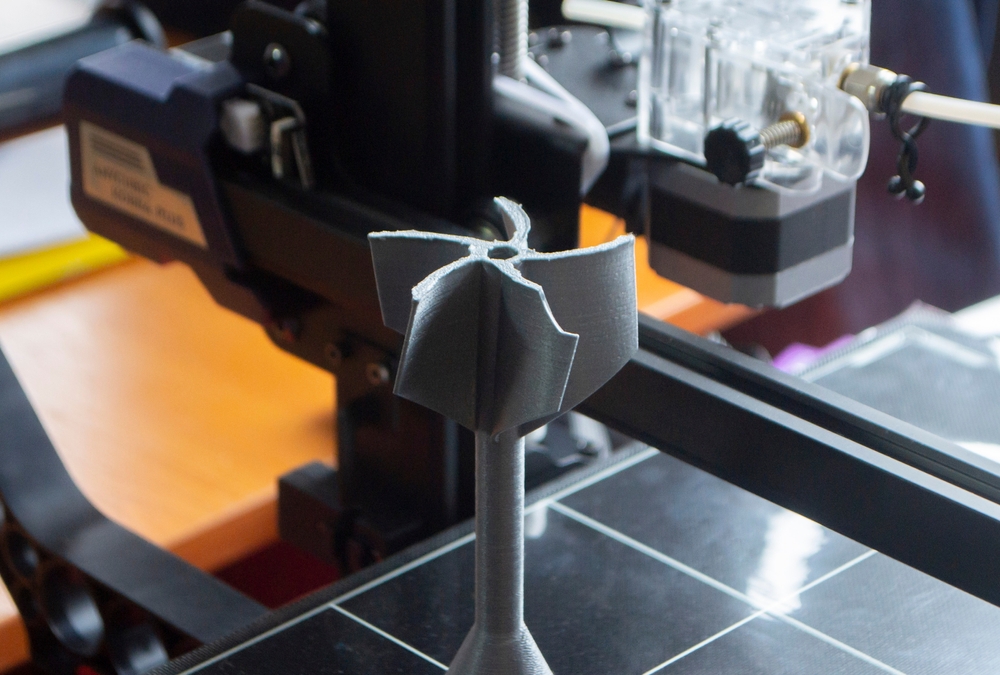

The rapid growth of additive manufacturing technologies has made 3D printer production a global priority, particularly for companies aiming to scale operations in regulated markets. As the demand for customized, fast, and precise 3D printing grows, so does the importance of adhering to strict certification standards. Manufacturers, compliance officers, and legal teams must ensure their equipment and processes align with international regulations to guarantee market readiness, customer trust, and legal protection.

This guide covers the most critical certifications required for 3D printer production, including ISO, CE, FCC, and other regional requirements. It also highlights how regulatory compliance influences product quality, international expansion, and brand reputation.

[widget-131]

Why Certifications Matter in 3D Printer Manufacturing

Certifications are more than just checkboxes—they are assurances of safety, consistency, and compliance. Regulatory bodies around the world require that manufacturers meet industry standards to ensure that equipment is:

- Safe for operators and end-users

- Consistent in performance and output

- Compliant with environmental and electromagnetic regulations

- Ready for international shipping and use

Failure to obtain the proper certifications may result in import bans, legal consequences, or product recalls. It can also damage the credibility of your brand in the eyes of clients and investors.

Key Certifications for 3D Printer Production

Let’s explore the major certifications that are typically required or expected in 3D printer production across different markets.

1. ISO Standards

The International Organization for Standardization (ISO) sets global benchmarks for quality, safety, and efficiency. For 3D printer production, the following ISO standards are highly relevant:

- ISO 9001: Quality Management Systems – proves that a company can consistently deliver quality products and services.

- ISO 14001: Environmental Management Systems – focuses on minimizing environmental impact in production.

- ISO/ASTM 52901: Additive Manufacturing – outlines general principles for design and manufacturing using 3D printing technologies.

- ISO/IEC 17025: Testing and calibration laboratories – ensures that testing facilities used in product development meet international benchmarks.

These certifications are particularly important for manufacturers aiming to export products or partner with global clients.

2. CE Marking (Conformité Européenne)

If your company plans to sell 3D printers in the European Economic Area (EEA), CE certification is mandatory. It shows that your product meets European Union health, safety, and environmental standards.

Products bearing the CE mark have undergone conformity assessments covering areas such as:

- Mechanical safety

- Electromagnetic compatibility (EMC)

- Low voltage electrical safety

- RoHS (Restriction of Hazardous Substances)

CE compliance is particularly important when aiming to serve the highly regulated EU market, ensuring a smoother path through customs and distribution networks.

3D printer production systems intended for European clients must follow this pathway, and professional consultation is often advised during CE documentation.

3. FCC Certification (Federal Communications Commission – USA)

In the United States, FCC certification is required for any device that emits radiofrequency radiation, including many 3D printers that incorporate Wi-Fi, Bluetooth, or electromagnetic components.

FCC Part 15 covers:

- Interference with other electronic devices

- Safety limits for RF exposure

- Labeling requirements

FCC compliance ensures that your product can be sold legally in the U.S. without risk of seizure or penalty. It also communicates technical reliability and trustworthiness to buyers.

4. UL Certification (Underwriters Laboratories)

UL certification is a third-party safety certification especially important for electrical safety in consumer products. UL-listed 3D printers undergo rigorous testing for:

- Fire hazards

- Electrical faults

- Mechanical failure under load or extended use

This certification is often voluntary but strongly recommended for brand image, especially in North American markets.

Regional and Market-Specific Certifications

Aside from ISO, CE, FCC, and UL, different countries or regions may have their own unique regulatory requirements. For example:

- CSA (Canada): Similar to UL, it focuses on electrical and product safety.

- PSE (Japan): Required for electrical equipment sold in Japan.

- KC (South Korea): Ensures electromagnetic safety for consumer electronics.

- CCC (China Compulsory Certificate): Mandatory for electronics sold in China.

Manufacturers intending to operate globally should build compliance pathways for each target market. Failure to plan for localization can result in costly delays and reengineering.

How Certification Affects Production Costs and Planning

Obtaining certifications impacts not only documentation and approval cycles but also production budgets and timelines. For example, CE and FCC testing may require lab use, engineering reworks, and administrative overhead.

Understanding these costs early in your production planning phase will ensure smoother delivery schedules. Our cost of 3D printer production resource details how certification impacts financial projections and how to allocate budgets accordingly.

Additionally, certified equipment is more attractive to procurement departments, helping your products gain traction in competitive markets.

Erla’s Global Approach to Certified Production

At Erla’s Global, we understand the complexity of achieving full certification across multiple regions. Our engineering and compliance teams assist in:

- Aligning designs with ISO and CE requirements

- Preparing and managing documentation for regulatory audits

- Coordinating with authorized test laboratories

- Implementing Statistical Process Control (SPC) and traceability systems

When clients order custom 3D printer prototypes, we ensure that all steps—from material selection to final testing—meet global compliance standards. This integrated approach gives startups, scale-ups, and industrial partners the confidence to expand without legal setbacks.

Frequently Asked Questions

What is the most important certification for entering the EU market?

The CE marking is essential for entering the European Union. It indicates compliance with safety, health, and environmental protection directives and is legally required for electronics, including 3D printers.

Do I need both FCC and CE certifications?

Yes, if you plan to sell in both the U.S. and EU. FCC addresses radiofrequency compliance in the U.S., while CE covers broader safety and environmental factors in the EU.

How long does the certification process usually take?

Depending on the certification, it can take anywhere from 2 weeks (self-declaration CE) to 3–6 months (ISO, UL, FCC), especially if design changes or retesting are required.

Are certifications one-time processes?

No. Many certifications, such as ISO and UL, require annual audits or renewal applications. You must maintain documentation and ensure continuous compliance.

Can startups afford full certification?

Startups often struggle with certification costs, but starting with modular certification (e.g., for individual components) and outsourcing compliance steps can help manage budgets. Partnering with an experienced manufacturer like Erla’s Global can simplify the process.

Certification: The Gateway to Global-Ready 3D Printing

In the high-stakes world of additive manufacturing, certification is more than a requirement—it is a foundation for sustainable growth, safe user experiences, and international credibility. Whether you’re launching your first 3D printer or expanding to new regions, compliance with ISO, CE, FCC, and market-specific regulations ensures your products are future-proof and competitive.

Erla’s Global is here to guide you through every stage of certified production, from concept validation to final approval. With the right certifications in hand, your 3D printers won’t just work—they’ll win trust in every market they reach.