- Konu Başlıkları

- Why Choose Small Batch Production for Your 3D Printer Project?

- Our Flexible Manufacturing Solutions for 3D Printers

- Agile Production Workflows

- Advanced Prototyping Capabilities

- State-of-the-Art Precision Manufacturing

- Component Sourcing Expertise

- Scalable Pathways for Future Growth

- Who Benefits Most from Flexible Small Batch 3D Printer Production?

- Maintaining Quality and Consistency in Small Batch Runs

- Partner with Erlas Global for Your Small Batch 3D Printer Needs

- Conclusion: The Future of Niche Additive Manufacturing

- Frequently Asked Questions About Small Batch 3D Printer Production

In the dynamic world of additive manufacturing, not every project requires mass production. Startups launching innovative new models, companies developing specialized equipment for niche markets, or custom machinery builders often require lower volumes of high-quality 3D printers or their components. This is where small batch 3D printer production becomes the strategic answer. It offers the flexibility and agility needed to bring unique visions to life without the prohibitive costs and complexities of large-scale manufacturing. We understand the distinct needs of low-volume projects and provide flexible manufacturing solutions designed to support your innovation, from rapid prototyping to pilot runs and specialized equipment.

[widget-131]

Why Choose Small Batch Production for Your 3D Printer Project?

Small batch manufacturing offers distinct advantages over traditional mass production, especially for specific business models and product development cycles in the 3D printing industry.

- Reduced Upfront Investment: Avoid the massive capital outlay required for large-scale tooling and minimum order quantities (MOQs). This is ideal for startups and projects with limited initial funding, helping to control the overall cost of 3D printer production.

- Rapid Time-to-Market: Get your innovative 3D printer or specialized components to market faster. Small batches allow for quicker production cycles and faster deployment, seizing market opportunities ahead of competitors.

- Design Flexibility and Iteration: Small runs facilitate iterative design improvements. You can produce a batch, gather feedback, refine the design, and quickly produce an improved version, significantly accelerating product development. This is crucial for innovative products.

- Risk Mitigation: Test market demand, refine product features, or validate complex designs with lower risk. If adjustments are needed, they are less costly and time-consuming to implement in a small batch.

- Niche Market Specialization: Perfectly cater to highly specific, underserved markets that don't warrant mass production volumes. This allows for tailored features and higher perceived value.

- Quality Control Focus: With smaller volumes, it's often easier to maintain stringent quality control over each unit, ensuring exceptional precision and reliability.

For custom machinery builders and niche market players, small batch production is not just a viable alternative; it's a strategic competitive advantage that fosters innovation and market responsiveness.

Our Flexible Manufacturing Solutions for 3D Printers

Delivering high-quality small batch 3D printer production requires a manufacturing approach built on agility, adaptability, and precision. Our solutions are designed to support your unique project needs:

Agile Production Workflows

We implement agile manufacturing principles, allowing us to quickly reconfigure production lines, adapt to design changes, and manage diverse material requirements. This flexibility ensures that your project moves forward efficiently, even with evolving specifications. Our streamlined processes are optimized for dynamic requirements.

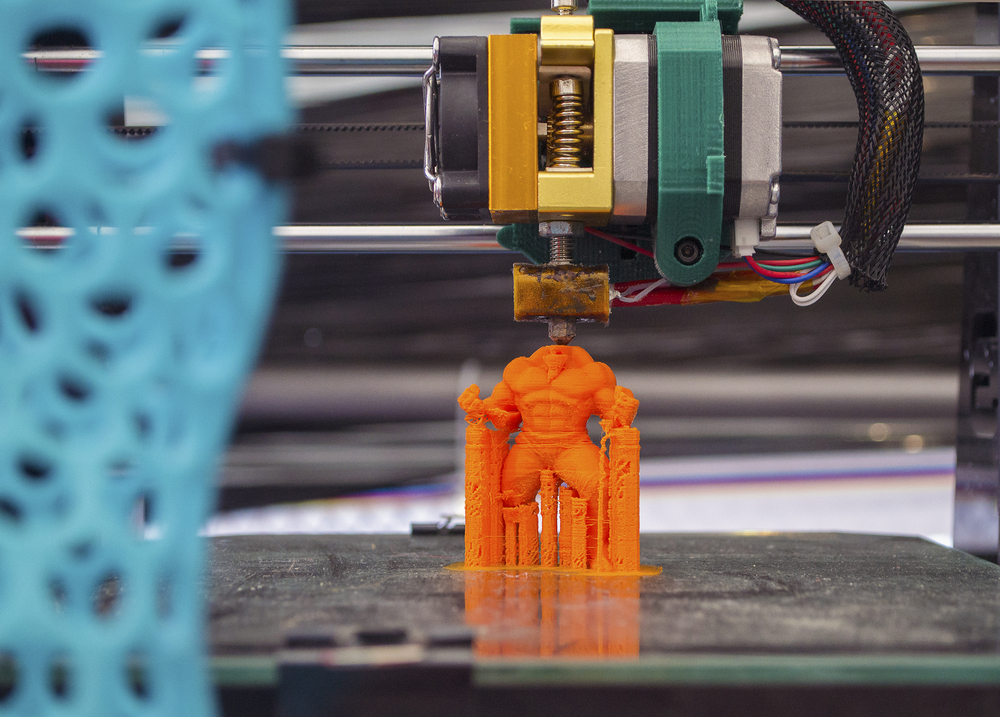

Advanced Prototyping Capabilities

Leveraging our expertise in rapid prototyping, we can quickly produce and test initial versions of your custom 3D printer or its components. This capability minimizes development cycles and ensures that the final design is robust and market-ready. Our ability to [order custom 3D printer prototypes](https://erlasglobal.com/order-custom-3d-printer-prototypes) is integral to our small batch offering.

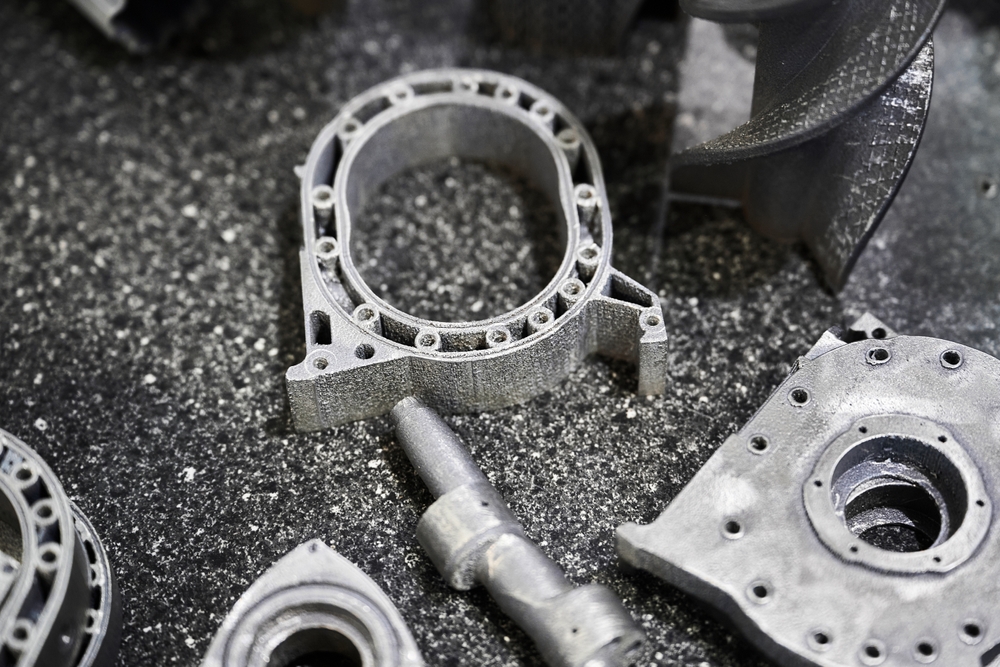

State-of-the-Art Precision Manufacturing

Despite lower volumes, we never compromise on quality. Our facilities utilize advanced CNC machining, precision assembly techniques, and automated quality control systems to ensure every unit meets the highest industry standards for accuracy and reliability. This maintains the integrity of your brand and product.

Component Sourcing Expertise

We have established a robust network of suppliers, allowing us to source specialized components efficiently for small batches. Our procurement team excels at finding high-quality materials and parts, even for unique or custom 3D printer designs, ensuring a seamless supply chain regardless of volume.

Scalable Pathways for Future Growth

Our small batch solutions are designed with future scalability in mind. As your market demand grows, we can seamlessly transition your production to larger volumes, leveraging our existing understanding of your product and streamlined processes. This provides a clear growth path without the need to switch manufacturers.

Who Benefits Most from Flexible Small Batch 3D Printer Production?

Our flexible manufacturing solutions are ideally suited for a range of clients and scenarios:

- Startups: Launching an innovative 3D printer or a new accessory requires controlled production runs to test market viability and gather early user feedback before committing to large-scale investment.

- Niche Market Innovators: Businesses targeting very specific industrial, medical, or artistic applications for which standard 3D printers are unsuitable. Small batch allows for highly specialized, custom-tailored solutions.

- Research & Development Labs: Academic or corporate R&D teams needing unique, custom-built 3D printing systems for experimental purposes or highly specific scientific applications.

- Custom Machinery Builders: Companies that integrate 3D printing technology into larger, bespoke industrial machines or automated systems, requiring specific, low-volume 3D printer modules.

- Pilot Programs: Organizations looking to test a new 3D printer concept or application in a controlled environment before full commercial rollout. Small batches provide ideal testing grounds.

- Exclusive or Limited Edition Products: Manufacturers creating high-value, limited-edition 3D printers or collector's items where exclusivity and craftsmanship are key.

If your project fits these descriptions, partnering with a manufacturer experienced in flexible, small batch 3D printer production can unlock significant value and accelerate your path to success.

Maintaining Quality and Consistency in Small Batch Runs

A common misconception is that small batch production compromises quality. On the contrary, our flexible manufacturing process is designed to maintain stringent quality standards for every single unit produced. This focus on individual excellence is a key differentiator, and it also informs our overall approach to providing a reliable [3D printing service](https://erlasglobal.com/3d-printing/3d-printing) to our clients.

- Dedicated Quality Checks: Each unit in a small batch often receives more individualized attention and rigorous inspection compared to a high-volume, fully automated line.

- Experienced Technicians: Our highly skilled technicians oversee critical assembly points and conduct comprehensive functional tests, ensuring precision is maintained across all units.

- Feedback Integration: The agile nature of small batch allows for immediate integration of feedback from testing or early users, leading to continuous improvement and higher quality for subsequent units within the same batch.

- Advanced Measurement & Calibration: We use sophisticated metrology tools to ensure dimensional accuracy and optimal performance of every component and the final assembled printer.

Our commitment to quality in small batch production means you receive reliable, high-performance 3D printers, regardless of the volume.

Partner with Erlas Global for Your Small Batch 3D Printer Needs

At Erlas Global, we pride ourselves on being more than just a manufacturer; we are your strategic partner in bringing innovative 3D printing solutions to life. Our expertise in small batch 3D printer production is underpinned by a commitment to agility, quality, and client support.

We understand the challenges and opportunities that come with specialized, low-volume manufacturing. Our flexible MOQs (Minimum Order Quantities), robust rapid prototyping capabilities, and lean manufacturing practices are designed to provide the ideal environment for your unique projects. We ensure your product maintains exceptional quality while keeping production costs optimized for your specific scale. Our extensive project portfolio and client testimonials reflect our ability to deliver tailored, high-performance solutions for diverse market needs.

Don't let volume constraints limit your innovation. Contact us today to discuss your project requirements and discover how our flexible manufacturing solutions can help you successfully launch your next groundbreaking 3D printer or specialized equipment. We are ready to support your vision with precision and agility.

Conclusion: The Future of Niche Additive Manufacturing

Small batch 3D printer production represents a vital segment of the additive manufacturing industry, enabling innovation and catering to specialized market demands that mass production cannot efficiently serve. Its inherent flexibility, cost-effectiveness for lower volumes, and rapid iteration capabilities make it an indispensable solution for startups, researchers, and niche market players.

By choosing a manufacturing partner with proven expertise in agile processes, advanced quality control, and scalable solutions, businesses can confidently bring their unique 3D printer concepts to fruition. Erlas Global stands ready to be that partner, transforming your innovative ideas into high-quality, market-ready products with precision and support, regardless of the batch size.

Frequently Asked Questions About Small Batch 3D Printer Production

- What is a typical Minimum Order Quantity (MOQ) for small batch 3D printer production?

MOQs for small batch production are significantly lower than mass production, often ranging from a single custom prototype to a few dozen or a few hundred units, depending on complexity. We offer flexible MOQs tailored to project needs. - How does small batch production affect per-unit cost?

While the total cost might be lower than mass production, the per-unit cost for small batches is generally higher due to less economies of scale in materials and setup times. However, it offers significant benefits in terms of flexibility, risk reduction, and time-to-market. - Can I scale up from small batch production to mass production later?

Yes, our small batch production processes are designed with scalability in mind. Once your product proves successful in a small batch, we can smoothly transition to larger volumes, leveraging established designs and supply chains. - Is small batch production only for custom 3D printers?

No, it's also ideal for pilot runs of standard models, specialized accessories, or components for existing 3D printers. It serves any need where high volume isn't necessary or desirable. - How long do small batch 3D printer production runs typically take?

Timelines vary based on complexity and volume, but small batches are significantly faster than mass production. They can range from a few weeks for simpler projects to a few months for highly complex custom systems.