- Konu Başlıkları

- Why Sustainability Matters in 3D Printing

- Reducing Carbon Footprint

- Minimizing Waste

- Enhancing Brand Reputation

- Strategies for a Sustainable 3D Printer Factory

- Adopting Eco-Friendly Materials

- Optimizing Energy Efficiency

- Implementing Waste Management Systems

- Leveraging Automation for Efficiency

- Case Study: A Green 3D Printer Factory

- Steps to Implement Sustainable Practices

- Common Pitfalls and How to Avoid Them

- Frequently Asked Questions (FAQs)

- What are the most effective sustainable practices for a 3D printer factory?

- How can I reduce energy consumption in my 3D printer factory?

- Are sustainable materials viable for high-volume 3D printing?

- Building a Greener Future with Erlas Global

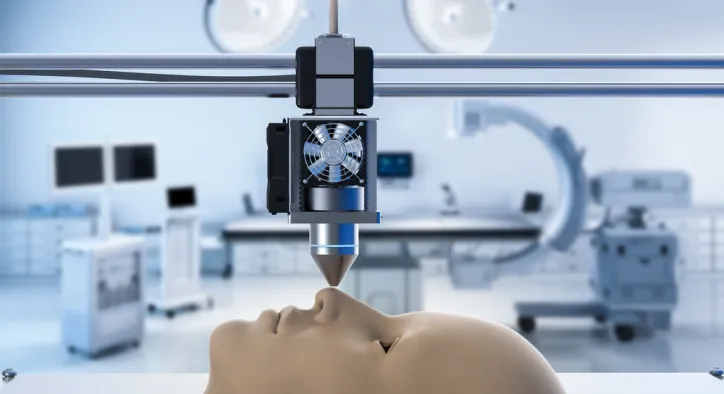

Sustainability is no longer optional for modern manufacturing; it’s a necessity driven by environmental responsibility and market demands. Creating a sustainable 3D printer factory involves integrating eco-friendly practices that reduce waste, conserve energy, and align with global sustainability goals. This comprehensive guide offers factory managers, environmental officers, and eco-conscious businesses practical strategies to transform their 3D printing operations into green, efficient, and responsible facilities.

Why Sustainability Matters in 3D Printing

3D printing, or additive manufacturing, is often praised for its efficiency compared to traditional manufacturing, but it still generates waste and consumes significant energy. Adopting green 3D printing practices reduces environmental impact, lowers operational costs, and enhances brand reputation. This section explores the key drivers of sustainability in 3D printer factories and their benefits.

[widget-131]

Reducing Carbon Footprint

3D printing factories can significantly lower their carbon footprint by optimizing energy use and adopting renewable energy sources. Energy-intensive processes like material extrusion and laser sintering require strategic interventions to minimize emissions.

Learn more about efficient manufacturing techniques that support sustainable production.

Minimizing Waste

3D printing waste reduction is critical for sustainability. Excess filament, failed prints, and packaging materials contribute to waste. Implementing closed-loop recycling systems and using biodegradable materials can mitigate these issues.

Enhancing Brand Reputation

Eco-friendly practices resonate with environmentally conscious consumers and regulators. Factories that achieve certifications like ISO 14001 or LEED gain a competitive edge in markets prioritizing sustainability.

Strategies for a Sustainable 3D Printer Factory

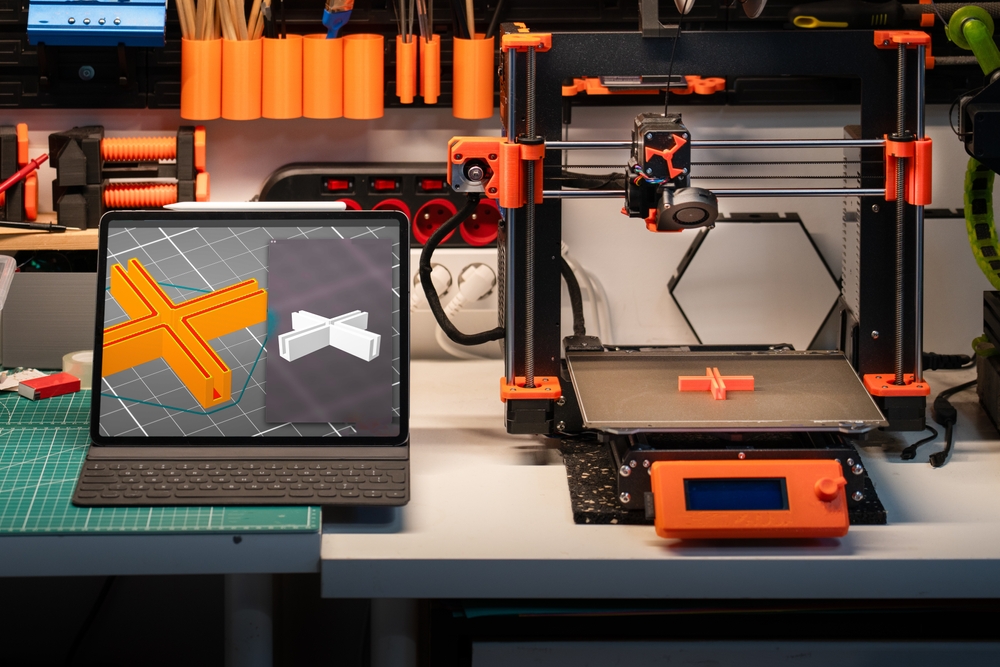

Implementing sustainable practices requires a holistic approach, from material selection to energy management. These strategies offer actionable steps for greener operations.

Adopting Eco-Friendly Materials

Eco-friendly 3D printer production starts with sustainable materials like biodegradable PLA, recycled ABS, and bio-based resins. These materials reduce environmental impact while maintaining performance. For example, PLA, derived from corn starch, is ideal for prototyping and decomposes naturally.

Testing custom prototypes with sustainable materials can validate their performance.

Optimizing Energy Efficiency

Energy-efficient 3D printing reduces operational costs and emissions. Conducting energy audits, upgrading to energy-efficient printers, and integrating renewable energy sources like solar panels are effective measures. A case study of a 3D printer factory showed that switching to LED lighting and energy-efficient motors reduced energy consumption by 25%.

Energy efficiency also impacts budgets, as explored in this guide on production costs.

Implementing Waste Management Systems

Closed-loop recycling systems collect and repurpose failed prints and excess filament. Partnering with recycling facilities ensures materials like ABS and PETG are reused. Additionally, minimizing packaging waste through sustainable alternatives like biodegradable wraps reduces landfill contributions.

Leveraging Automation for Efficiency

Sustainable additive manufacturing benefits from automation. Automated print farms optimize material usage, while AI-driven systems monitor energy consumption and reduce waste. For instance, predictive maintenance algorithms can prevent equipment failures, saving resources.

Case Study: A Green 3D Printer Factory

A mid-sized 3D printer factory implemented sustainable practices by adopting recycled PLA, installing solar panels, and using automated quality control. These changes reduced their carbon footprint by 30% and cut material waste by 40%. Achieving ISO 14001 certification boosted their market appeal, leading to a 20% increase in eco-conscious client contracts.

Steps to Implement Sustainable Practices

Follow these steps to transform your 3D printer factory into a sustainable operation:

- Conduct an Energy Audit: Identify high-consumption areas and prioritize upgrades.

- Adopt Sustainable Materials: Use biodegradable or recycled filaments.

- Implement Recycling Systems: Establish closed-loop processes for material reuse.

- Integrate Renewable Energy: Install solar or wind power systems.

- Pursue Certifications: Aim for ISO 14001 or LEED to validate sustainability efforts.

Common Pitfalls and How to Avoid Them

Sustainability initiatives can face challenges. Here are common pitfalls and solutions:

- High Initial Costs: Start with low-cost measures like LED lighting before scaling to solar panels.

- Material Limitations: Test eco-friendly materials to ensure performance meets standards.

- Lack of Expertise: Partner with environmental consultants to guide implementation.

Frequently Asked Questions (FAQs)

What are the most effective sustainable practices for a 3D printer factory?

The most effective practices include using biodegradable materials like PLA, implementing closed-loop recycling systems, and optimizing energy use through audits and renewable sources. Automation, such as AI-driven quality control, minimizes waste, while certifications like ISO 14001 validate your efforts and enhance credibility.

How can I reduce energy consumption in my 3D printer factory?

Start with an energy audit to identify inefficiencies, then upgrade to energy-efficient printers and LED lighting. Integrating renewable energy sources like solar panels and using smart sensors to monitor consumption can reduce energy use by up to 30%, as demonstrated in industry case studies.

Are sustainable materials viable for high-volume 3D printing?

Sustainable materials like recycled ABS and biodegradable PLA are viable for high-volume production, provided they meet performance requirements. Testing through prototyping ensures durability and quality. These materials lower environmental impact while maintaining cost-effectiveness for large-scale operations.

Building a Greener Future with Erlas Global

Implementing sustainable practices in your 3D printer factory is a strategic move that reduces environmental impact, lowers costs, and strengthens brand reputation. By adopting eco-friendly materials, optimizing energy use, and implementing robust waste management systems, factories can achieve measurable sustainability goals. Industry leaders like Erlas Global demonstrate how integrating ISO 14001 standards and renewable energy can drive eco-friendly production. Ready to make your factory greener? Start with these actionable strategies to build a sustainable, future-ready operation.