- Konu Başlıkları

- Key Challenges in Scaling 3D Printer Production

- Production Capacity Limitations

- Supply Chain Bottlenecks

- Quality Control at Scale

- Regulatory Compliance

- Strategies for Successful Scaling

- Leveraging Automation

- Optimizing Supply Chain Management

- Securing Financing for Growth

- Building a Scalable Workforce

- Case Study: Scaling Success in 3D Printing

- Common Pitfalls and How to Avoid Them

- Practical Tips for Scaling 3D Printer Production

- Frequently Asked Questions (FAQs)

- What are the first steps to scale 3D printer production?

- How can automation help in scaling production?

- What are the risks of scaling too quickly?

- Achieving Mass Market Success in 3D Printing

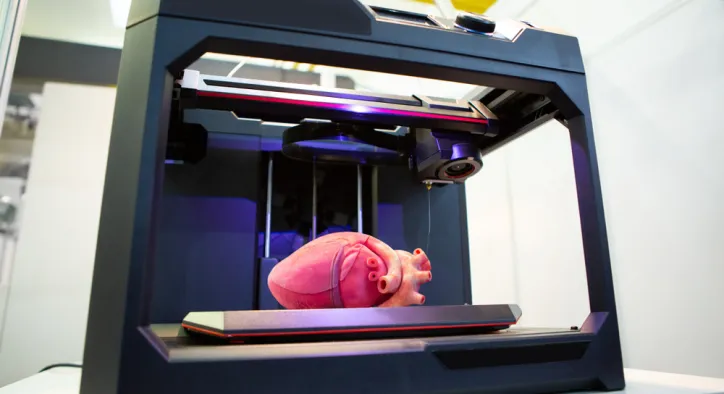

Transitioning from a prototype to mass production is a pivotal moment for startups and growing businesses in the 3D printing industry. Scaling 3D printer production requires strategic planning, robust infrastructure, and a deep understanding of market demands. This comprehensive guide provides actionable insights for entrepreneurs and investors aiming to expand their production capacity while avoiding common pitfalls. From optimizing manufacturing processes to securing financing, this resource equips you with the tools to achieve mass market success.

Key Challenges in Scaling 3D Printer Production

Scaling production introduces complexities that can derail unprepared businesses. Understanding these challenges is the first step toward a successful expansion.

[widget-131]

Production Capacity Limitations

3D printer mass production demands increased output without compromising quality. Small-scale setups often lack the equipment or expertise to handle high volumes. Upgrading to industrial-grade printers or integrating hybrid manufacturing (e.g., CNC machining) can address this.

Learn more about advanced manufacturing techniques to support your scaling efforts.

Supply Chain Bottlenecks

A robust supply chain is critical for sourcing materials and components at scale. Delays in filament supply or electronic parts can halt production. Just-in-time inventory systems and diversified supplier networks mitigate these risks.

Quality Control at Scale

Scaling additive manufacturing requires rigorous quality control to maintain consistency across thousands of units. Implementing ISO 9001 standards and automated inspection systems ensures reliability.

Quality control impacts budgets, as explored in this guide on production costs.

Regulatory Compliance

Mass production must comply with international standards like CE, RoHS, and FCC. Navigating these regulations requires expertise to avoid costly delays or fines.

Strategies for Successful Scaling

Effective scaling involves a combination of technology, processes, and financing. These strategies help businesses meet market demands efficiently.

Leveraging Automation

3D printing production expansion benefits from automation. Automated print farms, robotic assembly lines, and AI-driven quality checks reduce labor costs and improve throughput. For example, a print farm with 50 printers can produce thousands of components daily.

Testing automation on custom prototypes can validate scalability before full investment.

Optimizing Supply Chain Management

Scaling requires a resilient supply chain. Partnering with multiple suppliers, using predictive analytics for demand forecasting, and adopting just-in-time delivery minimize disruptions. A case study of a 3D printer startup showed that diversifying suppliers reduced lead times by 30%.

Securing Financing for Growth

3D printer production growth demands significant capital for equipment, facilities, and workforce expansion. Options include venture capital, bank loans, or government grants for advanced manufacturing. A clear business plan with ROI projections is essential to attract investors.

Building a Scalable Workforce

A skilled team is vital for managing increased production. Training programs for 3D printing technicians and hiring supply chain experts ensure operational efficiency. Cross-functional teams can address bottlenecks proactively.

Case Study: Scaling Success in 3D Printing

A startup specializing in desktop 3D printers scaled from 100 to 10,000 units annually within two years. By investing in automated print farms, diversifying suppliers, and securing $5M in venture capital, they achieved a 40% cost reduction per unit. Compliance with CE standards enabled entry into European markets, boosting revenue by 60%.

Common Pitfalls and How to Avoid Them

Scaling introduces risks that can undermine growth. Here are common pitfalls and mitigation strategies:

- Overestimating Demand: Conduct market research to validate demand forecasts.

- Underfunding Expansion: Secure sufficient capital to cover equipment and operational costs.

- Neglecting Quality: Implement automated quality checks to maintain standards.

- Ignoring Compliance: Partner with regulatory experts to ensure adherence.

Practical Tips for Scaling 3D Printer Production

These actionable tips help businesses scale effectively:

- Start Small: Test scaling processes with a pilot production run.

- Invest in Technology: Adopt automation to boost efficiency.

- Build Partnerships: Collaborate with reliable suppliers and distributors.

- Monitor Metrics: Track production KPIs like yield rates and lead times.

- Plan for Growth: Develop a roadmap for future expansion phases.

Frequently Asked Questions (FAQs)

What are the first steps to scale 3D printer production?

Begin by validating market demand through research and pilot production runs. Invest in scalable technologies like automated print farms and optimize your supply chain with diversified suppliers. Secure financing to cover equipment and operational costs.

How can automation help in scaling production?

Automation, such as robotic assembly and AI-driven quality control, increases throughput, reduces labor costs, and ensures consistency. Automated print farms can produce thousands of units daily, enabling businesses to meet mass market demands efficiently.

What are the risks of scaling too quickly?

Scaling too quickly can lead to supply chain disruptions, quality issues, and financial strain. Overestimating demand or underfunding expansion can result in excess inventory or production delays. Mitigate these risks with thorough planning and incremental scaling.

Achieving Mass Market Success in 3D Printing

Scaling 3D printer production from prototype to mass market is a complex but rewarding journey. By leveraging automation, optimizing supply chains, securing financing, and addressing regulatory requirements, businesses can meet growing demand while maintaining quality. With strategic planning and a focus on risk mitigation, startups and growing companies can achieve sustainable growth and thrive in the competitive 3D printing industry. Ready to scale your production? Use these insights to chart your path to mass market success.