- Konu Başlıkları

- Understanding the Cost Drivers in 3D Printer Manufacturing

- Strategy 1: Design for Manufacturability (DfM) and Value Engineering

- Strategy 2: Supply Chain Optimization and Strategic Sourcing

- Strategy 3: Automation and Process Efficiency

- Strategy 4: Quality Management and Defect Reduction

- Balancing Cost and Quality: The Erlas Global Approach

- Conclusion: Smart Savings for a Competitive Edge

- Frequently Asked Questions About 3D Printer Production Cost Optimization

In the competitive landscape of additive manufacturing, managing production costs is paramount for profitability and market leadership. For CFOs, procurement managers, startups, and established manufacturers alike, the challenge is clear: how do you reduce expenses in 3D printer production without sacrificing the quality, performance, or reliability that customers demand? This isn't just about cutting corners; it's about smart, strategic cost optimization 3D printer production through efficient processes, intelligent sourcing, and advanced manufacturing techniques. Let’s explore actionable strategies to maximize your manufacturing budget and achieve sustainable savings.

[widget-131]

Understanding the Cost Drivers in 3D Printer Manufacturing

Before optimizing, it's crucial to understand where the costs in 3D printer production typically originate. The primary cost drivers include:

- Material Costs: Raw materials for components (metals, plastics, electronics, optics) often constitute a significant portion.

- Labor Costs: Skilled labor for assembly, calibration, and quality control.

- Research & Development (R&D): Investment in design, prototyping, and innovation for new models or improvements.

- Manufacturing Overhead: Factory utilities, equipment maintenance, depreciation, and facility costs.

- Quality Control & Testing: Rigorous testing procedures to ensure product reliability and performance.

- Logistics & Supply Chain: Transportation, warehousing, and inventory management.

Each of these areas presents opportunities for strategic optimization, impacting the overall financial efficiency of your operations.

Strategy 1: Design for Manufacturability (DfM) and Value Engineering

Cost optimization begins at the design stage. Integrating Design for Manufacturability (DfM) and value engineering principles can significantly reduce production expenses before manufacturing even begins.

- Simplify Designs: Reduce part count by integrating multiple functions into single components. Simpler designs require fewer manufacturing steps and less assembly time.

- Standardize Components: Utilize readily available, standard off-the-shelf components wherever possible instead of custom-fabricated ones. This reduces sourcing complexity and leverages economies of scale.

- Material Optimization: Select materials that meet performance requirements but are also cost-effective and easy to process. For instance, choosing appropriate plastics over more expensive metals when feasible.

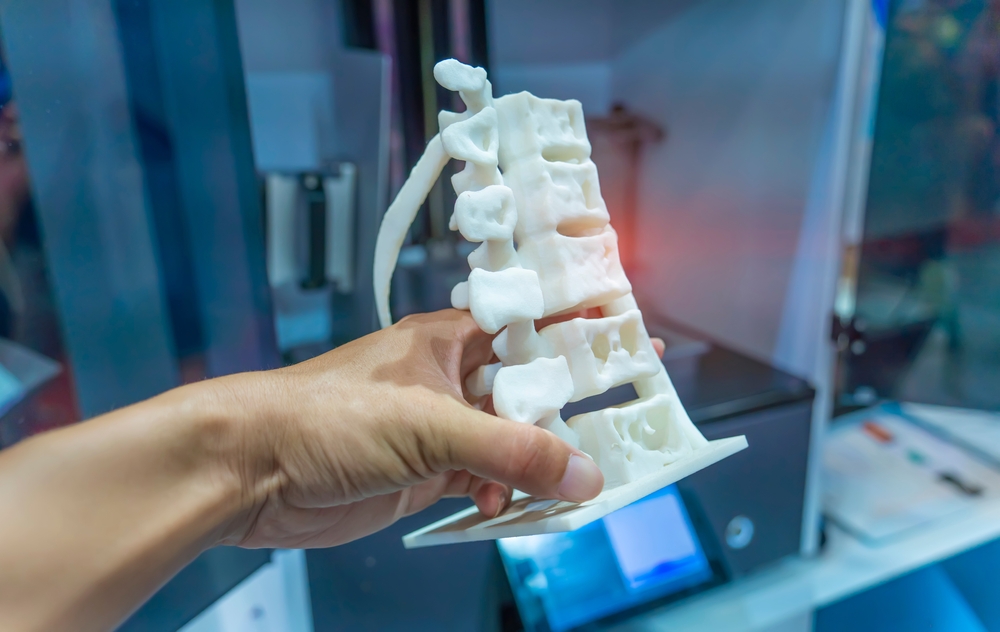

- Optimize for Manufacturing Processes: Design parts specifically for the chosen production methods (e.g., injection molding, CNC machining, or even order custom 3D printer prototypes for rapid, cost-effective iterations), minimizing waste and processing time.

Value engineering involves systematically analyzing product functions to achieve them at the lowest possible cost without compromising quality. This proactive approach saves substantial costs downstream in the production lifecycle.

Strategy 2: Supply Chain Optimization and Strategic Sourcing

The efficiency of your supply chain directly impacts manufacturing costs. A well-managed supply chain can unlock significant savings in component procurement and logistics for all aspects of 3D printer production.

- Bulk Purchasing & Volume Discounts: Consolidate orders and negotiate better pricing with suppliers for larger volumes of components.

- Strategic Supplier Relationships: Build long-term partnerships with trusted suppliers. This can lead to preferential pricing, faster lead times, and collaborative design improvements.

- Global Sourcing & Local Alternatives: Balance the cost benefits of global sourcing with the logistical advantages and risk reduction of local suppliers, especially for critical components.

- Inventory Management: Implement Just-In-Time (JIT) inventory systems to reduce carrying costs, warehousing expenses, and the risk of obsolescence. This minimizes capital tied up in inventory.

- Supplier Diversification: Avoid relying on a single supplier for critical parts. Having alternative sources can mitigate risks associated with supply chain disruptions and price fluctuations, which can inflate overall cost of 3D printer production.

A resilient and optimized supply chain isn't just about cost savings; it's about ensuring consistency and reliability, which indirectly reduces costs associated with delays and quality issues.

Strategy 3: Automation and Process Efficiency

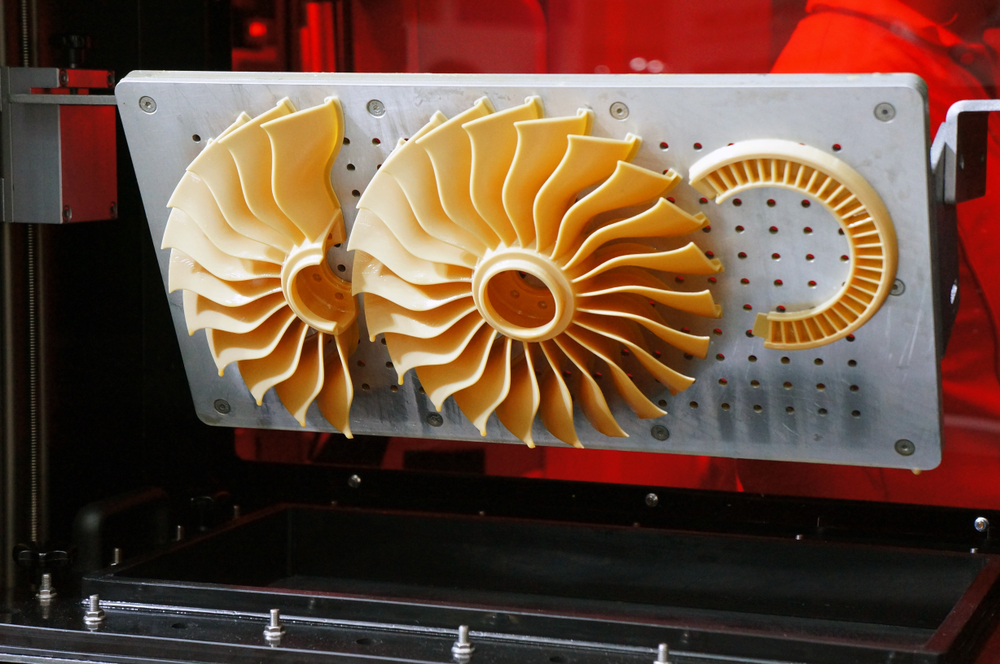

Investing in automation and continuously improving manufacturing processes are powerful levers for cost reduction in 3D printer factories.

- Automated Assembly: Deploy robotics and automated systems for repetitive assembly tasks. This reduces labor costs, increases production speed, and improves consistency, leading to fewer errors and less rework.

- Lean Manufacturing Principles: Implement lean methodologies to identify and eliminate waste across all production stages. This includes minimizing overproduction, waiting times, excessive motion, over-processing, excess inventory, defects, and unused talent.

- Optimized Production Flow: Streamline the factory layout and production sequence to reduce bottlenecks and ensure a smooth, continuous flow of products through the assembly line.

- Preventative Maintenance: Regular maintenance of manufacturing equipment prevents costly breakdowns and extends machine lifespan, reducing unexpected repair expenses and production downtime.

- Energy Efficiency: Optimize energy consumption in the manufacturing facility through efficient machinery, smart lighting, and energy management systems. Even small reductions in utility bills can add up.

Automation and lean practices don't just save money; they enhance overall production efficiency and product quality, contributing to a stronger competitive position.

Strategy 4: Quality Management and Defect Reduction

While often seen as an additional cost, robust quality management is a significant cost-saving strategy. Preventing defects is far cheaper than correcting them post-production or dealing with warranty claims and customer dissatisfaction.

- Early Defect Detection: Implement in-line quality control checks and automated inspection systems at various stages of production. Catching defects early, when components are cheaper and easier to replace, saves substantial rework costs.

- Statistical Process Control (SPC): Use data and statistical methods to monitor and control production processes, identifying variations that could lead to defects before they occur.

- Supplier Quality Management: Work closely with suppliers to ensure the quality of incoming components, reducing the likelihood of faulty parts disrupting your assembly line.

- Employee Training & Empowerment: Invest in training your workforce on quality standards and empower them to identify and address issues, fostering a culture of quality ownership.

By minimizing rework, reducing scrap, and enhancing product reliability, effective quality management directly contributes to lower overall production costs and higher customer satisfaction.

Balancing Cost and Quality: The Erlas Global Approach

At Erlas Global, we understand that cost optimization in 3D printer production is a delicate balance. Our expertise lies in implementing these strategies without ever compromising the precision, durability, and performance that define a superior 3D printer. We focus on:

- Integrated Value Engineering: Our design teams actively work to simplify and standardize, ensuring cost-effectiveness from the blueprint stage.

- Strategic Sourcing & Partnerships: We leverage our global network and long-standing supplier relationships to secure the best quality components at competitive prices.

- Advanced Automation & Lean Practices: Our state-of-the-art facilities utilize automation and lean principles to drive efficiency and reduce waste in assembly.

- Rigorous Quality Assurance: Our multi-layered QC system prevents costly defects, ensuring every unit meets stringent standards before it leaves our factory.

Our goal isn't just to produce 3D printers; it's to produce them in the most efficient and cost-effective way possible, passing those savings and efficiencies onto our clients without ever sacrificing the integrity of the product. This commitment makes us a reliable partner for companies aiming to optimize their manufacturing budgets.

Conclusion: Smart Savings for a Competitive Edge

Optimizing costs in 3D printer production is a multifaceted challenge, but one that yields significant returns. By strategically applying principles like Design for Manufacturability, optimizing your supply chain, embracing automation, and prioritizing robust quality management, manufacturers can achieve substantial savings without compromising product quality or market competitiveness.

These strategies not only improve your bottom line but also enhance overall operational efficiency and product reliability, building a stronger foundation for growth in the dynamic additive manufacturing industry. Partnering with an expert like Erlas Global, who understands these nuances, ensures your investment in 3D printer manufacturing is both efficient and exceptional. Start exploring how smart cost optimization can transform your production today.

Frequently Asked Questions About 3D Printer Production Cost Optimization

- What is Value Engineering in 3D printer production?

Value engineering involves a systematic process of analyzing the functions of a 3D printer and its components to achieve those functions at the lowest total cost while maintaining or improving quality and performance. - Can automation really reduce costs for smaller manufacturers?

Yes, even partial automation (e.g., robotic pick-and-place for specific assembly tasks, automated testing) can significantly reduce labor costs and improve consistency, making it viable for small and medium-sized manufacturers to optimize their operations. - How does supplier relationship management impact costs?

Strong supplier relationships lead to better negotiated prices, more favorable terms, improved communication, and often collaboration on component design, all of which contribute to direct and indirect cost savings over time. - Is it possible to cut costs without affecting quality?

Absolutely. Effective cost optimization focuses on improving efficiency, reducing waste, and making smarter design and sourcing choices. True optimization avoids compromising quality, as defects and rework ultimately increase costs. - What is the role of continuous improvement in cost optimization?

Continuous improvement (e.g., Kaizen, Lean principles) fosters a culture of ongoing efficiency gains. Regularly reviewing processes, identifying bottlenecks, and implementing small, incremental changes can lead to substantial long-term cost reductions.