- Konu Başlıkları

- The Role of 3D Printing in Modern Prototyping

- Why 3D Printer Production Is Ideal for Prototyping

- Speed and Agility

- Cost-Effectiveness

- Complex Geometry

- Material Diversity

- Real-World Applications of 3D Printer Production for Prototyping

- The Prototyping Process with Erlas Global

- When to Use 3D Printer Production for Your Prototype

- Advantages for Startups and Product Innovators

- The Future of 3D Prototyping with Erlas Global

- Conclusion

- Frequently Asked Questions

In today’s fast-paced product development landscape, the ability to quickly turn concepts into physical models can significantly shorten design cycles, reduce costs, and accelerate innovation. This is where 3D printer production for prototyping emerges as a transformative force. With the evolution of additive manufacturing technologies, engineers and designers now enjoy unparalleled freedom to experiment, test, and validate their ideas without the constraints of traditional fabrication methods.

This article delves deep into how 3D printer production supports the prototyping process, how businesses leverage it for speed and precision, and how Erlas Global delivers cutting-edge solutions for innovators worldwide.

[widget-131]

The Role of 3D Printing in Modern Prototyping

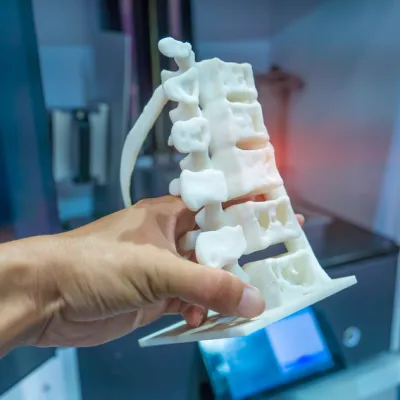

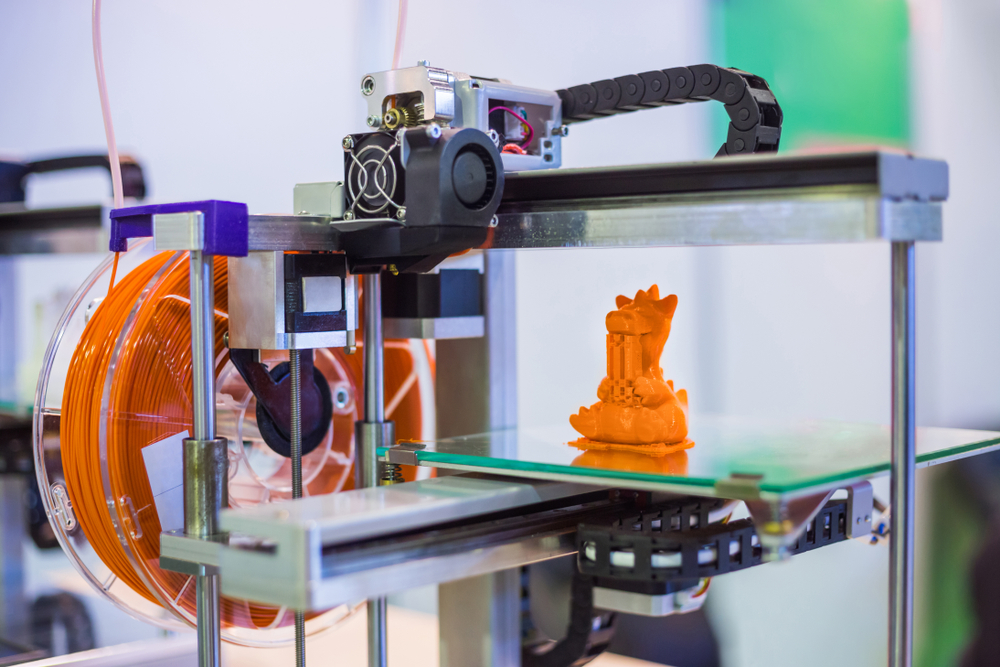

Prototyping is an essential stage in product development. It enables creators to visualize, test, and refine concepts before moving to full-scale production. 3D printing offers a flexible, fast, and cost-efficient method to produce these prototypes using various materials like plastics, resins, or even metal powders.

Unlike subtractive methods such as CNC machining, which remove material to shape a product, 3D printer production builds prototypes layer by layer. This technique opens up design possibilities that were previously impossible due to tooling limitations or material constraints.

Why 3D Printer Production Is Ideal for Prototyping

Here are key reasons why businesses are increasingly turning to 3D printer production for prototyping:

Speed and Agility

One of the most critical advantages is rapid iteration. Engineers can go from CAD model to physical prototype in a matter of hours, enabling same-day testing and feedback.

Cost-Effectiveness

Traditional prototyping may require molds or complex setups. With 3D printer production, there’s no need for expensive tooling, especially during the early design phases.

Complex Geometry

Designs with intricate internal channels or organic shapes are now feasible. 3D printers can produce geometries that would be impossible or prohibitively expensive using traditional methods.

Material Diversity

Whether it’s thermoplastics, resin, or composite filaments, a wide range of materials are available depending on the prototype’s functional requirements.

Real-World Applications of 3D Printer Production for Prototyping

From aerospace components to medical devices, 3D printing has found its way into nearly every industry. Here are some examples:

- Automotive: Rapid testing of aerodynamic parts, interior design prototypes, and ergonomic components.

- Healthcare: Custom prosthetics, anatomical models, and surgical guides.

- Consumer Products: Housing for electronics, footwear designs, and wearable tech.

Erlas Global has contributed to numerous innovation journeys by offering tailored prototyping services. Startups, in particular, benefit greatly from the flexibility of 3D printer production, which allows them to pivot, test, and refine ideas at a fraction of the time and cost.

The Prototyping Process with Erlas Global

At Erlas Global, the prototyping process starts with understanding the client’s objectives and functional requirements. Using industrial-grade 3D printers and design expertise, the team supports clients through each phase—from modeling to material selection to final print optimization.

A recent project with a wearable tech startup illustrates the impact of 3D prototype production. The client required multiple iterations of a compact housing design that had to balance aesthetics, fit, and airflow. Through 3D printing, Erlas Global delivered successive prototypes within days, enabling rapid design adjustments based on user testing.

Such projects not only highlight Erlas’s technical expertise but also its responsiveness and commitment to innovation.

When to Use 3D Printer Production for Your Prototype

While 3D printing is highly versatile, it's particularly advantageous in certain scenarios:

- Early Concept Validation: Quickly test the look and feel of your product.

- Functional Testing: Verify mechanical performance before tooling.

- Marketing Samples: Create realistic mockups for presentations and investor pitches.

- User Experience Testing: Collect feedback on ergonomics and usability.

By working with a professional 3D printing service, developers ensure accurate builds, proper scaling, and material choices that align with their design intent.

Advantages for Startups and Product Innovators

For startups, where time and budget are critical, 3D printer production offers an incredible value proposition. It levels the playing field, giving small teams access to manufacturing capabilities that were once reserved for large corporations.

Here’s how 3D printing helps early-stage ventures:

- Speeds up investor-ready prototypes

- Enables market testing before mass production

- Reduces development risks with early testing

- Facilitates IP development by quickly turning concepts into tangible assets

Startups can iterate, learn, and grow their ideas with confidence—without the fear of sunk costs or long lead times.

The Future of 3D Prototyping with Erlas Global

As 3D printing technologies evolve, the line between prototyping and production continues to blur. With new materials, multi-material printers, and improved surface finishes, functional end-use parts are becoming more common.

Erlas Global stays ahead of the curve by continually upgrading its machinery, software, and design workflows. By combining technical knowledge with client-centric processes, Erlas ensures that every prototype delivers value, insight, and momentum.

Conclusion

3D printer production for prototyping is no longer a niche tool—it’s a core component of modern product development. From rapid iterations to functional testing, it empowers businesses to innovate with speed and precision. Whether you're a startup aiming to validate your next big idea or a company refining your product line, 3D printing offers unmatched flexibility and efficiency.

Erlas Global stands as a reliable partner in this journey, bringing ideas to life through expert consultation, high-quality prints, and fast turnaround. Don’t let your ideas stay on paper—prototype them with purpose.

[widget-136]

Frequently Asked Questions

What industries benefit most from 3D prototyping?

Industries like automotive, healthcare, aerospace, and consumer electronics frequently use 3D prototyping for design validation and testing.

How fast can a 3D prototype be created?

Depending on complexity and size, some prototypes can be produced in under 24 hours.

What materials are used in 3D printer production for prototypes?

Materials range from PLA and ABS to resins and high-performance polymers like nylon and PEEK.

Is 3D printing accurate enough for engineering prototypes?

Yes, especially with industrial-grade printers, accuracy can be within ±0.1mm or better, suitable for most engineering needs.

Can I create functional prototypes with moving parts?

Absolutely. Advanced printers and flexible materials make it possible to create assemblies with interlocking or moving parts.