- Konu Başlıkları

- 3D Architectural Printing: A Revolution in Future Building Design

- What is 3D Architectural Printing?

- 3D Architectural Printing Service: From Design to Reality

- 3D Architectural Drawing: The Basic Step of Design

- 3D Architectural Modeling: 10 Steps in Digital Design!

- 1. Determining Project Goals

- 2. Preparing the Digital Design of the Structure

- 3. Creating a Detailed Model of the Structure

- 4. Material and Texture Selection

- 5. Lighting and Shading Applications

- 6. Physical and Structural Testing of the Structure

- 7. Client or Investor Presentations

- 8. Revision and Finalization of the 3D Architectural Model

- 9. Production of the Physical Model

- 10. Realized Project

- 3D Architectural Printer: The Power of Technology

- 3D Architectural Model Creation: Infinite Possibilities for Creative Designs

- Shape the Future with 3D Architectural Printing

- Show Your Difference with 3D Architectural Printing

3D Architectural Printing: A Revolution in Future Building Design

With the rapid advancement of technology, there is a major transformation in the world of architectural design. Construction projects of the future now include not only imagination but also advanced technologies. One of these technologies is 3D architectural printing. So, what is 3D architectural printing and why has it become so important? In this article, we will examine in detail what 3D architectural printing is, how it works and how it revolutionizes the construction industry.

[widget-131]

What is 3D Architectural Printing?

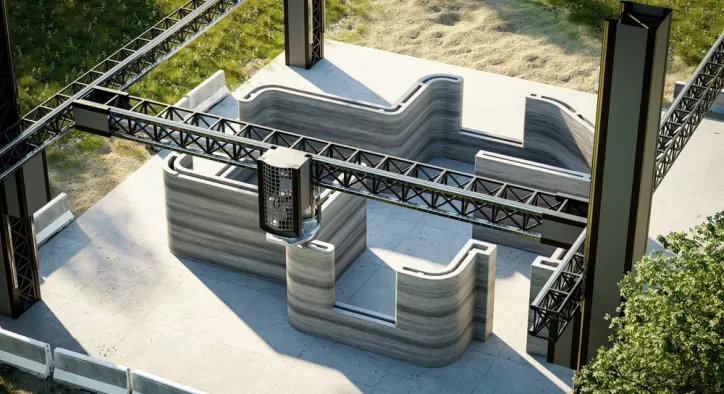

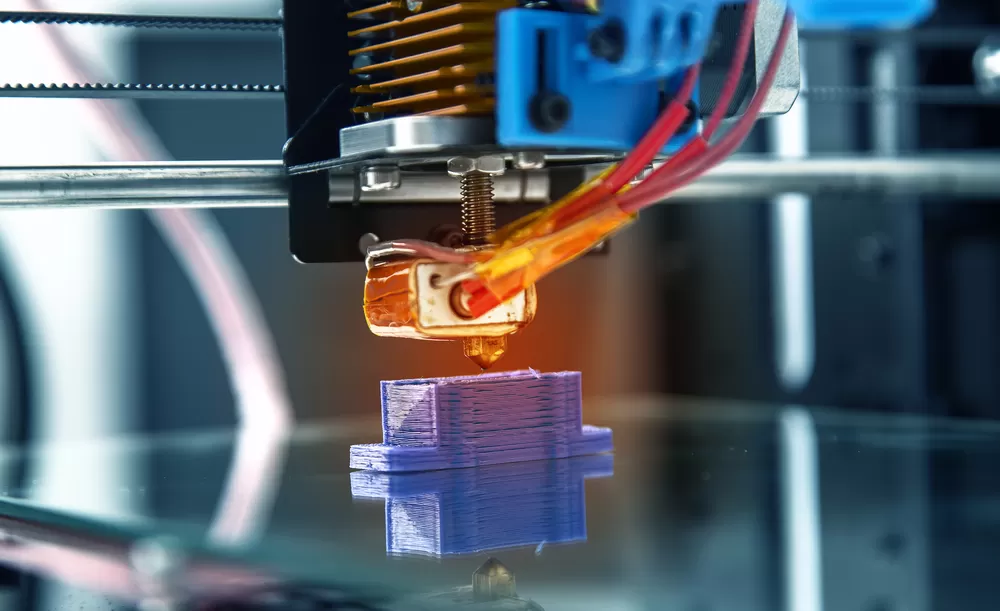

3D architectural printing is the physicalization of the digital design of a structure or model using a special 3D printer. This technology is used to transform 3D architectural modeling processes made with computer-aided design (CAD) software into a concrete structure. 3D architectural printers used in the construction industry allow the creation of structures built with various materials such as concrete, plastic and even metals.

3D Architectural Printing Service: From Design to Reality

3D architectural printing service offers an important opportunity not only for professional designers and engineers, but also for construction companies and investors. This service is a process where architectural drawings are produced accurately and every detail of the construction can be tested. With 3D architectural printing, changes made at every stage of the design can be applied quickly, time losses are prevented and projects can be completed more efficiently.

This service can be much faster and less costly than traditional construction methods. For example, the process of creating a 3D architectural model can be completed in a much shorter time than traditional construction methods, which allows projects to be implemented quickly.

3D Architectural Drawing: The Basic Step of Design

3D architectural drawing visually creates the basic design of a structure. These drawings are usually the first documents prepared when the project is started and help architects, engineers and builders understand what kind of structure they will build. 3D architectural printing technology makes these drawings three-dimensional and allows them to be used much more effectively at every stage of the projects.

3D Architectural Modeling: 10 Steps in Digital Design!

3D architectural modeling is the process of creating a structure or space in a digital environment. This process is usually carried out with computer-aided design software. 3D modeling helps architects and engineers visualize their designs in detail. In this way, every aspect of any structure can be examined before the construction process.

The biggest advantage of a 3D architectural printing service process is that design errors can be detected before the construction phase. In addition, the durability and functionality of the structure can be tested with simulations made on these models.

1. Determining Project Goals

Before starting the 3D architectural modeling process, all requirements and goals for the project are determined. This stage forms the basis of the modeling process and allows designers to understand which details will be at the forefront.

2. Preparing the Digital Design of the Structure

Architects and engineers collect all the necessary data about the structure and transfer this data to the 3D modeling software. This allows a digital "draft" version of the structure to emerge. At this stage, the first drawings and designs are created with 3D architectural modeling techniques.

3. Creating a Detailed Model of the Structure

The 3D architectural modeling process continues with the creation of every detail of the structure in a digital environment. This covers every aspect from interior arrangements to exterior design. Each layer, window, door and other architectural elements are added to the model with precision.

4. Material and Texture Selection

During the modeling stage, materials and textures are selected for the exterior surfaces, interiors and decoration elements of the structures. These selections make the structure look realistic and allow designers to better present their projects.

5. Lighting and Shading Applications

During the 3D architectural printing service process, the natural light and artificial lighting conditions of the structure are also taken into consideration. This stage makes the design more realistic and aesthetic. Details are emphasized on the model with light effects and shading techniques.

6. Physical and Structural Testing of the Structure

The 3D model is used to test the physical properties of the structure before it is built. This allows the durability, safety and structural integration of the structure to be simulated. Additionally, these digital models can be quickly updated when structural changes or improvements are required.

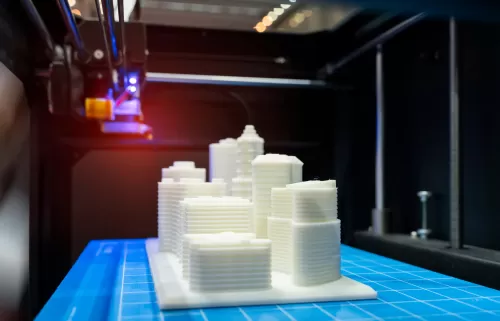

7. Client or Investor Presentations

The 3D architectural drawing process is very effective in presenting projects to clients or investors. Investors can visually examine all the details before the project is completed, thus increasing confidence in the project and possible changes can be made early.

8. Revision and Finalization of the 3D Architectural Model

Necessary changes are made to the design in line with the feedback made on the model. This process is one of the most important steps regarding 3D architectural printing service because each update allows the design to be perfected.

9. Production of the Physical Model

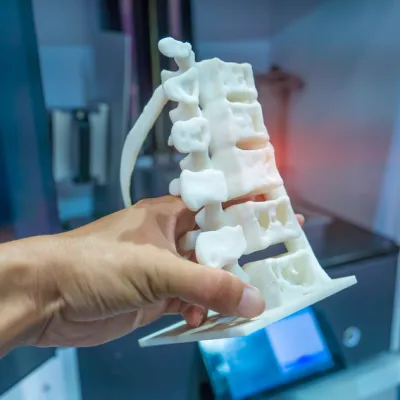

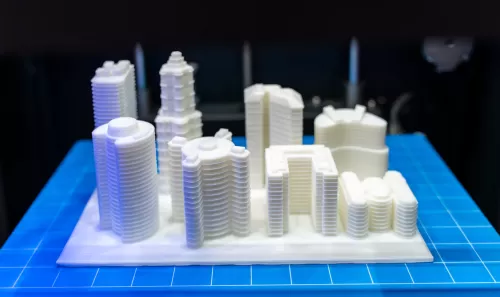

The 3D architectural drawing process sometimes ends with the production of the digital model as a physical model. Using 3D printers, the digital design is made physical and a more concrete version of the project is obtained. This is especially useful for complex designs.

10. Realized Project

After all these stages are completed, the design created with the 3D architectural printing service process turns into the construction process. The architectural project steps from the digital world to the physical world, and every detail is built based on the accuracy of this model.

3D Architectural Printer: The Power of Technology

3D architectural printers are machines that enable a digital model to become a physical structure, and these printers have the ability to work with various materials. Prints made with materials such as concrete, polymers and metal are much more environmentally friendly and faster than traditional construction methods. These printers also allow architects to create complex and original designs that were previously unimaginable.

Traditional construction methods are intensive and costly in terms of time and labor. However, 3D architectural printers not only provide fast production, but also enable projects to be realized at low cost. These printers have the capacity to produce not only architectural structures but also interior designs and prototypes.

3D Architectural Model Creation: Infinite Possibilities for Creative Designs

3D architectural model creation is one of the most critical stages of the design process. 3D printing technology offers architects a wide range of creativity at this stage. Complex geometric shapes, interior arrangements and different building styles can be easily modeled and printed. This process provides a great advantage especially for projects that require personalized designs.

In the process of creating a 3D architectural model, every detail of the model is designed in a digital environment and optimized for printing on a printer. This both saves time and enables the investment in the project to be used efficiently.

Shape the Future with 3D Architectural Printing

As a result, 3D architectural printing is a potential technology that will revolutionize the construction industry. This technology speeds up the design process, reduces costs and allows for environmentally friendly structures to be built. Thanks to 3D architectural printing, it is now much easier to turn your dream project into reality.

3D architectural printing service offers the best solution for those who want to use this revolutionary technology. You can design your designs in a digital environment with 3D architectural modeling and 3D architectural drawing techniques and turn them into reality quickly and efficiently using 3D architectural printers. Thanks to the opportunities offered by this technology, creating innovative projects in the construction world is now easier and more accessible.

[widget-136]

Show Your Difference with 3D Architectural Printing

If you also want to undertake the architectural projects of the future, you can bring your designs to life using 3D architectural printing technology with us. This technology not only provides speed and cost advantages, but also enables original and creative projects. With 3D architectural model creation, 3D architectural printers and other related technologies, you can make a difference in the architecture sector. As Erlas, you can pioneer innovations in the sector by using technology with our vision and foresight.