- Konu Başlıkları

- 3D Prototype Production in Aviation: The Technology of the Future

- Basic Features of 3D Prototype Production in Aviation

- 3D Prototype Solutions for Modern Aviation Projects

- Lightweight and Durable Parts: Performance and Fuel Savings

- Rapid Prototyping: Fast Solutions from Design to Production

- Cost Savings: Less Material and Labor

- Design Flexibility: Complex and Innovative Solutions

- Environmentally Friendly Production: Sustainability and Efficiency

- Areas of Use of 3D Prototype Production in Aviation

- The Future of 3D Printing in the Aviation Sector

- 3D Prototype Production in Aviation with Erlas

3D Prototype Production in Aviation: The Technology of the Future

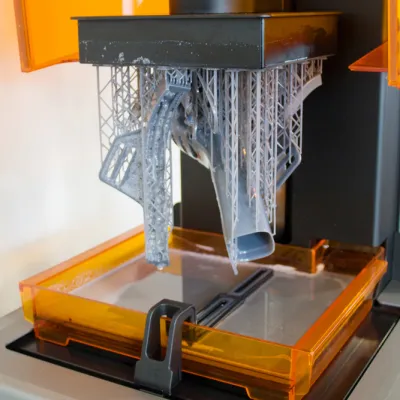

3D prototype production in aviation stands out as an innovative technology that radically changes design and manufacturing processes. 3D printers, which enable the rapid and low-cost production of complex and precise parts in the aviation industry, have created a major revolution in the sector. This technology offers a wide range of applications from the design of critical components such as aircraft fuselages, engine components and aerodynamic parts to the testing phase.

[widget-131]

Basic Features of 3D Prototype Production in Aviation

3D prototype production in aviation refers to the conversion of digital designs into physical parts with additive manufacturing technology. This process both shortens design time and significantly reduces costs. It increases aircraft performance and provides fuel savings, especially by enabling the use of complex geometries and lightweight materials.

Easy production of complex designs.

Production of lightweight but durable parts.

Lower costs compared to traditional methods.

3D Prototype Solutions for Modern Aviation Projects

3D prototype printing in the aviation sector offers many advantages over traditional methods by optimizing production processes. Innovative 3D printing technology allows projects to be completed in a shorter time by providing flexibility in design, fast production and cost savings. Advantages of 3D prototyping in the aviation industry:

Lightweight and Durable Parts: Performance and Fuel Savings

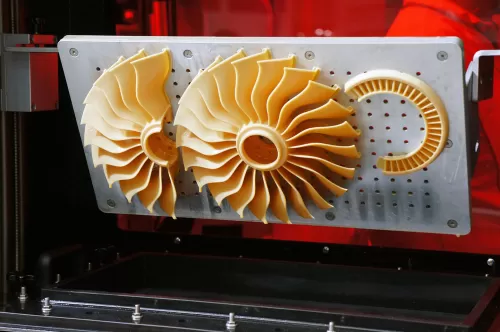

Aviation prototype production 3D printing technology is ideal for producing lightweight but durable parts. The use of lightweight materials reduces the weight of aircraft and spacecraft, which reduces fuel consumption and provides significant savings in operational costs. Durability increases safety and offers long-term use.

Fuel Savings: Aviation prototype production 3D printer, aircraft weight reduction, less fuel consumption.

Durability: Parts produced with 3D prototype production in aviation are resistant to harsh conditions.

Performance Increase: Aviation prototype production 3D printer, lightweight and aerodynamic designs increase aircraft performance.

Rapid Prototyping: Fast Solutions from Design to Production

3D prototype production in aviation allows designs to be converted into physical models in a short time. This rapid production process allows engineers to test their designs at an early stage and make necessary adjustments. This minimizes errors and allows projects to progress quickly.

Rapid Testing: Engineers can quickly test their designs by prototyping them.

Time Savings: Production times are significantly shortened compared to traditional methods.

Optimized Production: Aviation prototype production 3D printers detect errors early and ensure the perfection of the final product.

Cost Savings: Less Material and Labor

In the aviation industry, 3D prototype production reduces costs by optimizing assembly processes and material usage. Waste and high labor costs, which are frequently encountered in traditional production methods, are minimized with 3D printing.

Material Savings: Aviation prototype production 3D printers prevent waste by using only the required amount of material.

Ease of Assembly: Complex components are produced in one go, reducing the need for assembly.

Economic Solutions: 3D prototype printing in the aviation industry provides cost advantages due to lower labor and energy usage.

Design Flexibility: Complex and Innovative Solutions

3D printing in the aviation sector allows engineers to easily produce complex and innovative designs. Detailed geometries that are difficult to produce with traditional methods become possible thanks to 3D printers.

Complex Geometries: Detailed and special designs can be easily produced with 3D printing in the aviation sector.

Innovative Solutions: Aviation prototype production 3D printer technology allows the development of new technologies.

Project Customization: With 3D printing in the aviation sector, special components for different projects can be designed quickly.

Environmentally Friendly Production: Sustainability and Efficiency

3D prototype production in the aviation industry offers an environmentally friendly production process by using only the required material. This technology exhibits a sustainable approach thanks to the reduction of waste and energy savings.

Prevention of Material Waste: Less waste is generated with 3D printing in the aviation sector compared to traditional methods.

Energy Efficiency: Aviation prototype production 3D printer system reduces environmental impacts with less energy consumption.

Recyclable Materials: Sustainable manufacturing processes are supported with 3D prototyping in the aviation industry.

3D prototype production in aviation makes engineering and manufacturing processes more efficient, economical and environmentally friendly. These advantages ensure that 3D printing technology has an indispensable place in the future of the aviation industry.

Areas of Use of 3D Prototype Production in Aviation

Aviation prototype production 3D printing technology is used in many areas in the sector. Here are the main areas of use of this technology:

Aircraft Body and Parts: Aircraft body and aerodynamic parts can be easily designed and produced thanks to 3D prototype production in aviation.

Engine Components: 3D prototype printing in the aviation sector offers high precision and durable solutions for engine components.

Spare Part Production: Fast spare part production becomes possible thanks to 3D printing in the aviation sector. This provides a significant advantage especially in emergency situations.

Prototype Development: 3D prototype production in the aviation industry offers an effective solution for testing and developing new designs.

The Future of 3D Printing in the Aviation Sector

3D prototype production in aviation will become even more widespread in the future. With the development of new material technologies and innovative designs, this technology will continue to transform production processes in the aviation sector. In particular, developments in sustainability and cost efficiency will increase the importance of this technology.

[widget-136]

3D Prototype Production in Aviation with Erlas

As Erlas, we offer innovative solutions in 3D prototype production technology in aviation. We add value to your projects with our lightweight, durable and cost-effective solutions at every stage from the design process to production. With our high-precision 3D printers and expert team, we provide the best solutions for your projects in the aviation sector. Let's shape the future together!

3D prototyping in aviation makes engineering and manufacturing processes more efficient, economical and environmentally friendly. These advantages ensure that 3D printing technology has an indispensable place in the future of the aviation industry.