- Konu Başlıkları

- 3D printing manufacturers in aviation: The technology that will shape the future of aviation

- The power of 3D printing in aviation

- Aircraft interior design

- Advantages of 3D printing in the aviation sector

- Lightweight and durable - 3d printing manufacturers in aviation

- Environmental benefits - 3d printing manufacturers in aviation

- Custom designs - 3d printing manufacturers in aviation

- Flexibility in production processes

- Less logistics effort - 3d printing manufacturers in aviation

- Reliability and increased performance - 3d printing aviation companies

- Global production networks - 3d printing aviation companies

- The use of 3D printers in aviation and future expectations

3D printing manufacturers in aviation: The technology that will shape the future of aviation

In recent years, 3D printing companies in the aviation industry have seen a significant increase due to technological revolutions. The use of 3D printing, especially in the aviation sector, has both changed production processes in the sector and significantly reduced costs. The production of complex and delicate parts in the aviation sector has been a time-consuming and costly task for many years, but thanks to 3D production in the aviation sector, these difficulties are gradually being overcome.

[widget-131]

The power of 3D printing in aviation

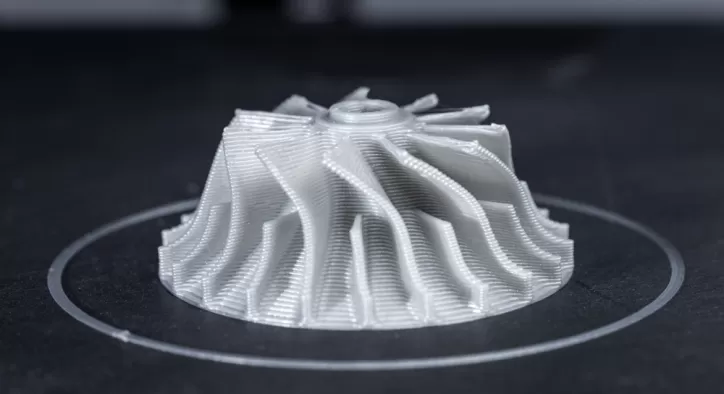

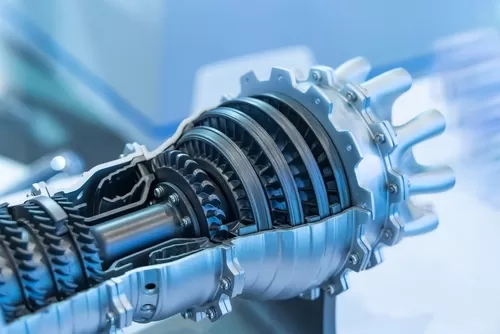

3D printing manufacturers in the aviation sector have made a big difference, especially in engine components and cabin interiors. Parts that would take months to manufacture with traditional production methods can be completed in a few days with 3D printers. 3D printing in aviation industry for example, turbine blades used in aircraft engines become both lighter and more durable with 3D printing technology. This saves fuel and reduces CO2 emissions.

The most common areas where 3D printing aviation companies

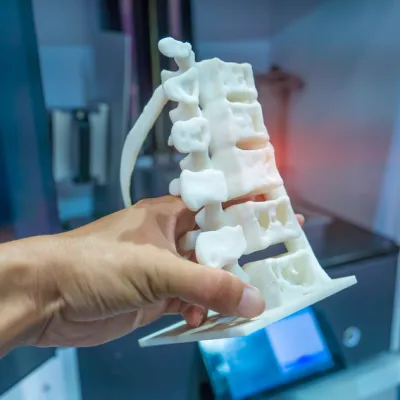

3D printing in aviation is primarily used in aircraft engine components and interior designs. Especially in the production of parts with complex geometries, 3D printing manufacturers in aviation offer more advantageous solutions compared to traditional methods. 3D printing is also at the forefront in spare part production. Airlines can reduce logistics costs by producing aircraft parts on-site using 3D printers on demand.

Aircraft interior design

The interior parts of passenger aircraft are being significantly optimized with the use of 3D printing manufacturers in aviation. Cabin partitions, seat parts and decorative elements are both lighter and more durable thanks to 3D printing. This reduces the weight of the aircraft, saves fuel and provides flexibility in interior design. It is also possible to create interior designs specifically designed for customer needs. For example, individual designs such as ergonomic seat components that increase passenger comfort or larger storage areas are being implemented using 3D printing technology.

These examples show that the use of 3D printing in the aviation sector not only reduces production costs, but also offers innovative and sustainable solutions. 3D production in the aviation industry aims to speed up 3d production in aviation industry operations while reducing environmental impact.

Advantages of 3D printing in the aviation sector

The aviation sector is being shaped by innovative technologies every day, and 3D printing manufacturers in aviation are at the center of this change. 3D printing in aviation pushes the boundaries of traditional production methods, providing cost and time savings as well as an environmentally friendly production approach. The production of lighter, more durable and customizable parts increases aircraft performance and provides operational flexibility. In addition, 3D printing in the aviation sector creates a sustainable and efficient supply chain by reducing logistics efforts. This technology, which attracts attention with both economic and environmental benefits, continues to be one of the fundamental forces shaping the aviation sector of the future.

Lightweight and durable - 3d printing manufacturers in aviation

In the aerospace industry, 3D printing offers the opportunity to create parts from lightweight yet extremely durable materials. This reduces the overall weight of the aircraft and uses less fuel. Reducing fuel consumption significantly reduces both airline costs and CO2 emissions.

Environmental benefits - 3d printing manufacturers in aviation

3D printing offers an environmentally friendly method by minimizing material waste during the production process. The large amount of material waste that occurs in traditional manufacturing is significantly reduced with 3D printing in aviation. Most of the material used is converted directly into the product, meaning more sustainable production.

Custom designs - 3d printing manufacturers in aviation

The use of 3D printing in aviation enables the production of individual designs with complex geometries. This means that precision parts such as aircraft engines and interior decorative elements can be individually adapted to customer needs. Adaptive manufacturing opens the door to innovation in the aerospace industry.

Flexibility in production processes

3D manufacturing in the aerospace industry makes production processes more flexible. Traditional methods require expensive molds and tools to design a new part. However, 3D printing technology makes it possible to quickly transform a design from prototype to final product. This speeds up production processes and makes it easier to develop innovative solutions.

Less logistics effort - 3d printing manufacturers in aviation

3D printing in the aviation sector allows spare parts to be produced on-site. This reduces logistics costs and simplifies the spare parts supply chain. Especially in emergency situations, parts needed can be produced in a short time using 3D printing technology, speeding up operational processes.

Reliability and increased performance - 3d printing aviation companies

Parts produced with aviation 3D printing can have higher precision than parts made using traditional methods. This reduces maintenance costs thanks to long-lasting parts and increases the performance of the aircraft. High reliability is a decisive advantage in the aviation industry.

Global production networks - 3d printing aviation companies

Instead of limiting production to a specific region, aviation and aerospace 3D printing manufacturers can create distributed production networks around the world. This allows rapid response to local needs and increases flexibility in the aviation industry.

These benefits show that the use of 3D printers in aviation both increases production efficiency and takes a step towards a more sustainable and innovative future. 3D printing continues to transform the aviation industry by pushing the boundaries of technology.

[widget-136]

The use of 3D printers in aviation and future expectations

In the future, 3D production technology is expected to become even more widespread in the aviation sector. In particular, the production of equipment for space research by 3D printing manufacturers in aviation will give new momentum to the sector. In addition, on-site production allows for faster solutions.

3D printing aviation companies continue to revolutionize the aviation sector with the opportunities offered by technology. Especially in the 3d printing in aviation industry, 3D printing is shaping the aviation sector of the future with its cost advantages, lightness, longevity and environmentally friendly production options. These rapid developments in the sector point to a more sustainable future for both airlines and manufacturers. The use of 3D printing in aviation will already be one of the fundamental technologies of tomorrow.