- Konu Başlıkları

- A Technological Step in the Shoe Industry…

- What is 3D Shoe Printing?

- Advantages of 3D Shoe Printing

- 1. Rapid Prototyping and Design Changes

- 2. Customization and Custom Production

- 3. Less Waste and Environmentally Friendly Production

- 4. Less Storage and Stock Cost

- 5. Production of Complex Designs

- Parts That Can Be Produced with 3D Printing in the Shoe Industry

- Is 3D Shoe Printing Costly?

- You Can Have 3D Shoe Printing for Your Company and Brand!

A Technological Step in the Shoe Industry…

With the rapid advancement of technology, production processes in industries are also undergoing a major transformation. 3D shoe printing technology has also pioneered this transformation in the shoe industry. The shoe printing process with a 3D printer offers many advantages compared to traditional production methods. It provides great convenience and efficiency for shoe manufacturers at every stage from design to production.

[widget-131]

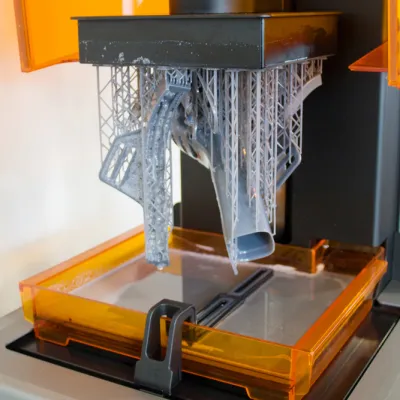

What is 3D Shoe Printing?

3D shoe printing is a production method that carries out the entire production process of a shoe from its design to its final form in a digital environment. Shoe printing with a 3D printer is the physicalization of digitally created designs through 3D printers. 3D printing in the shoe industry process can be done using different materials from plastic to metal. 3D shoe production offers a fast, flexible and customizable production process, so both small batches and special designs can be easily produced.

Advantages of 3D Shoe Printing

3D shoe printing provides many advantages in the shoe industry. Companies that make 3D printing for the shoe industry gain speed, flexibility, customization and cost advantages in their production processes. Here are some of these advantages:

1. Rapid Prototyping and Design Changes

3D printing shoe printing speeds up design processes. In traditional production methods, every change to the design requires making new molds. However, this problem is eliminated with 3D shoe production. Digital designs can be quickly converted to print, which provides flexibility in the design process. At the same time, rapid production of prototypes allows designers to test their ideas faster.

2. Customization and Custom Production

3D printing shoe production makes it possible to make personalized designs. The size, shape, colors and material of the shoe can be customized according to individual needs. Customers can personalize their shoes according to their own wishes, and manufacturers can respond quickly to this demand. This feature provides manufacturers with a great competitive advantage thanks to 3D shoe production.

3. Less Waste and Environmentally Friendly Production

3d printing in the shoe industry is much more environmentally friendly than traditional production processes. Large amounts of material waste occur during processes such as mold production and machining. However, shoe printing with a 3D printer minimizes material waste. Only the necessary material is used and no excess waste is produced. This creates an environmentally friendly production process.

4. Less Storage and Stock Cost

Shoe production with 3D printing makes it possible to produce on demand. With traditional methods, companies have to keep a large amount of stock. However, 3D shoe printing technology saves on large storage areas and stock costs by producing only for need. This offers manufacturers a significant cost advantage.

5. Production of Complex Designs

Shoe printing with a 3D printer enables the production of complex designs that are difficult or impossible with traditional production methods. Details on the outer surface of the shoe, supports in the inner structure or special shapes can be easily produced with 3D shoe printing. Shoe printing with 3d printer technology offers design freedom, allowing creative and innovative shoes to be produced.

Parts That Can Be Produced with 3D Printing in the Shoe Industry

3D printing shoe production can be used for many different parts of the shoe. Here are these parts:

Sole and Cushioning Systems: The sole and internal cushioning systems of the shoe can be produced with the shoe printing process with a 3D printer. This allows for both comfortable and aesthetically original sole designs.

Uppers: The upper part of the shoe can be designed with various materials using 3D shoe printing technology. Original uppers can be obtained with special patterns and different color combinations.

Outer Surface Details: Accessories and details on the outer surface of the shoe can be easily produced with 3D shoe printing technology. Special stitches, labels and other decorations can be created quickly and flexibly in 3d printing in the shoe industry.

Internal Structure and Supports: Support systems and structural elements in the internal structure of the shoe can be produced using 3D printing shoe production. This increases the durability of the shoe and provides comfortable use.

Is 3D Shoe Printing Costly?

At first glance, the process of printing shoes with a 3D printer may seem more costly than traditional production methods. However, in the long run, 3D shoe production provides many cost advantages. Especially in small batch production and customized designs, mold and labor costs are significantly reduced. In addition, minimizing material waste and on-demand production with 3D printing technology in the shoe industry also reduces companies' inventory costs.

In larger-scale production, although shoe production with 3D printing requires high initial investment, these investments can be returned in the short term with high efficiency and low-cost production. Manufacturers can minimize costs by making their production processes more efficient thanks to 3d printing in the shoe industry technology.

[widget-136]

You Can Have 3D Shoe Printing for Your Company and Brand!

3D shoe printing is a technology that has revolutionized the shoe industry. The shoe printing process with a 3D printer offers manufacturers design flexibility, cost savings, fast production and environmentally friendly solutions. 3D shoe production can be used in a wide range of applications, from the production of complex designs to the production of personalized shoes. If you are looking for innovative solutions in the shoe industry, you can transform your production processes with 3D shoe printing technology. By contacting us, you can get professional support on shoe printing with 3D printers and 3D shoe production. We offer high quality and efficient production services for solutions specific to your needs!