- Konu Başlıkları

- Understanding the Vulnerabilities: Common Supply Chain Disruptions

- Proactive Strategies for Building Supply Chain Resilience

- 1. Diversification of Suppliers and Geographic Sourcing

- 2. Enhanced Supply Chain Visibility and Transparency

- 3. Strategic Inventory Management

- 4. Modular Design and Component Standardization

- 5. Local and Regional Manufacturing Hubs

- Reactive Measures: Mitigating the Impact of Disruptions

- Building a Culture of Resilience: Beyond Tools and Tactics

- Erlas Global's Expertise in Supply Chain Resilience for 3D Printer Production

- Conclusion: Building a Future of Uninterrupted Innovation

- Frequently Asked Questions About 3D Printer Supply Chain Disruptions

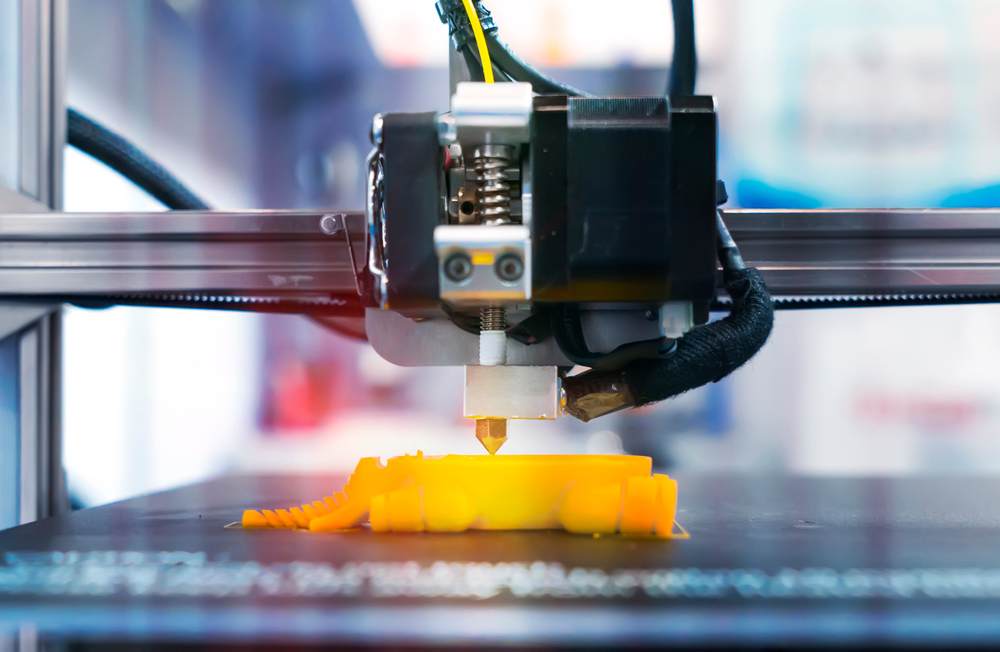

In the intricate world of modern manufacturing, even the most robust production lines can grind to a halt due to unforeseen challenges in the supply chain. For the specialized and often globally sourced components required for 3D printer production, these disruptions can be particularly devastating. From geopolitical tensions and natural disasters to raw material shortages and logistics bottlenecks, maintaining continuity in 3D printer manufacturing demands a proactive and resilient approach. Supply chain managers, business continuity planners, and risk management teams must understand not just the threats, but also the strategic solutions available to safeguard their operations and ensure a steady output of innovative additive manufacturing equipment.

[widget-131]

Understanding the Vulnerabilities: Common Supply Chain Disruptions

The first step in addressing supply chain disruptions is to identify their common sources and understand their potential impact on 3D printer manufacturing.

- Geopolitical and Trade Tensions: Tariffs, trade wars, and political instability in key manufacturing regions can restrict the flow of critical components like microchips, specialized alloys, or optical systems.

- Natural Disasters and Climate Events: Earthquakes, floods, and extreme weather can directly impact manufacturing facilities, transportation routes, and raw material extraction sites.

- Raw Material Shortages: Increased demand, mining limitations, or geopolitical controls can lead to scarcity and price volatility for essential materials such as rare earth metals, specific polymers, or specialized ceramics.

- Logistics and Transportation Issues: Port congestion, shipping container shortages, rising fuel costs, or labor disputes can delay the movement of goods globally.

- Cyberattacks and Data Breaches: Disruptions to IT systems within the supply chain, affecting ordering, tracking, or production scheduling.

- Supplier Bankruptcy or Failure: The unexpected collapse of a key supplier can leave manufacturers without crucial components.

Each of these vulnerabilities poses a unique threat, potentially leading to increased costs, production delays, and ultimately, a loss of market share. This highlights why effective 3D printer production relies heavily on a resilient supply chain.

Proactive Strategies for Building Supply Chain Resilience

Building a resilient supply chain for 3D printer production isn't about reacting to crises; it's about embedding preventative measures and agility into your operational framework.

1. Diversification of Suppliers and Geographic Sourcing

Relying on a single source or region for critical components is a major vulnerability. Diversifying your supplier base across different geographical regions reduces dependency and spreads risk. This means identifying alternative suppliers and qualifying them proactively, even if they aren't your primary source. This strategy provides fallback options during regional disruptions.

2. Enhanced Supply Chain Visibility and Transparency

Understanding every tier of your supply chain, not just direct suppliers, is crucial. Leveraging technologies like blockchain, IoT sensors, and advanced analytics can provide real-time data on component movement, inventory levels, and potential bottlenecks. This heightened visibility allows for earlier detection of issues and more informed decision-making, helping to manage the overall cost of 3D printer production by preventing costly delays.

3. Strategic Inventory Management

While Just-In-Time (JIT) minimizes carrying costs, a "just-in-case" approach with strategic buffer stocks for critical components can be vital during disruptions. Identifying essential parts and maintaining a sensible safety stock level can prevent production lines from halting completely during unforeseen shortages.

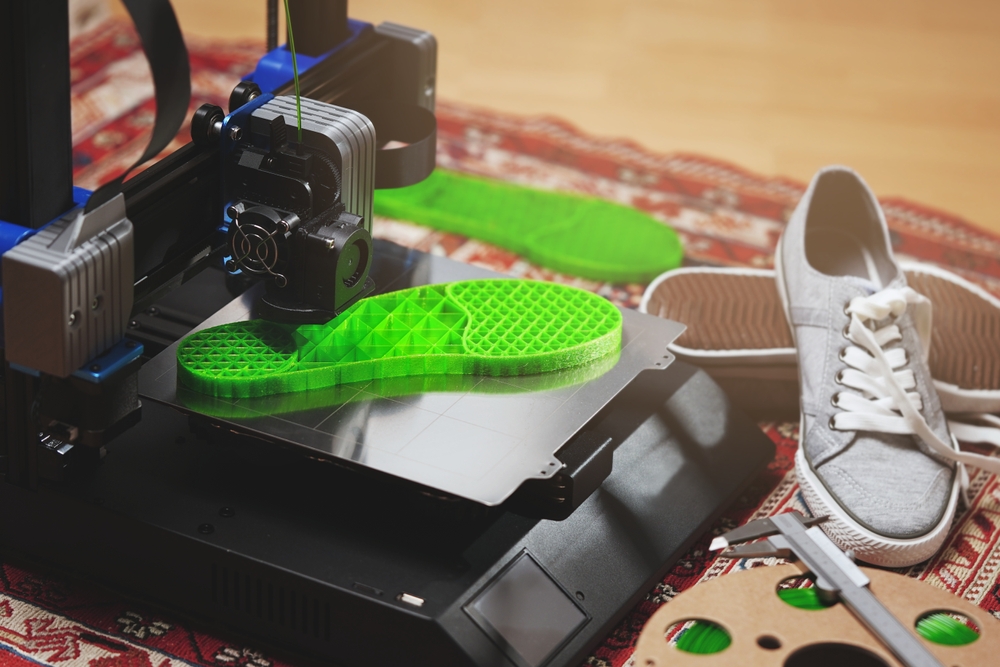

4. Modular Design and Component Standardization

Designing 3D printers with modular components allows for greater flexibility in sourcing and easier substitution of parts during a disruption. Standardizing certain non-proprietary components across different printer models also increases procurement flexibility and reduces reliance on highly specialized, single-source parts.

5. Local and Regional Manufacturing Hubs

While global supply chains offer cost benefits, establishing local or regional manufacturing and assembly hubs can significantly reduce lead times and exposure to international shipping disruptions. This strategy supports localized markets and builds a more robust, distributed production network.

Reactive Measures: Mitigating the Impact of Disruptions

Even with robust proactive strategies, disruptions can occur. Effective reactive measures are essential for minimizing their impact and maintaining business continuity.

- Rapid Risk Assessment and Communication: Quickly assess the scope and potential impact of the disruption. Transparent and timely communication with internal teams, suppliers, and customers is paramount to managing expectations and coordinating responses.

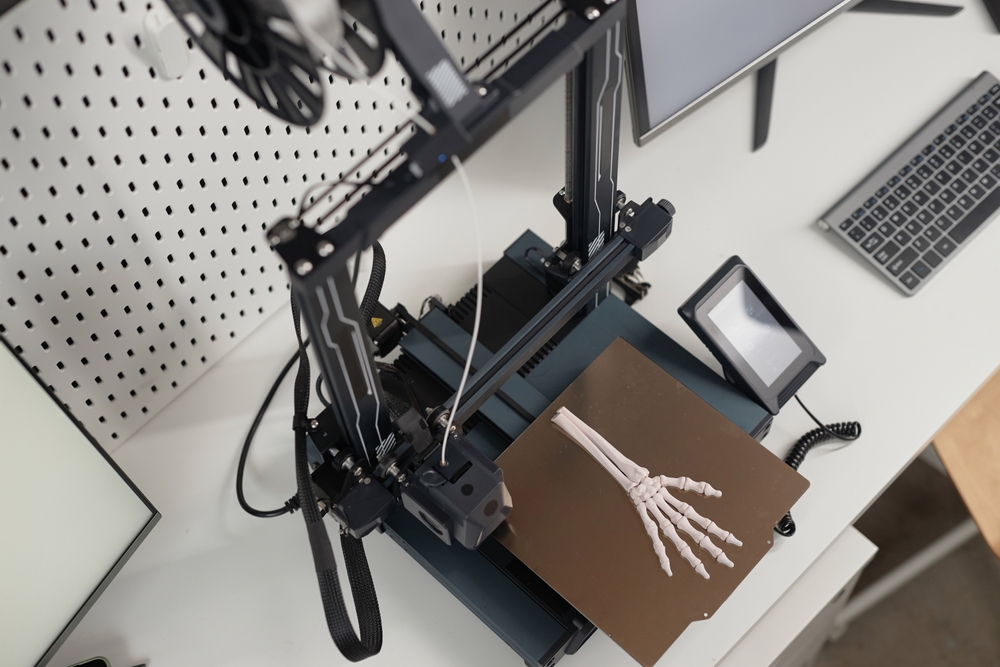

- Expedited Sourcing and Logistics: Activate pre-vetted alternative suppliers and utilize expedited shipping methods for critical components. This may involve paying premiums, but it often outweighs the cost of lost production or market opportunities. Our expertise in order custom 3D printer prototypes and rapid manufacturing can be leveraged here for quick, essential part fabrication.

- Production Line Flexibility: Adapt production schedules and prioritize critical product lines. Cross-training staff and having flexible manufacturing equipment can enable quick shifts in output.

- Contingency Planning and Crisis Management Teams: Establish clear contingency plans for various disruption scenarios. Dedicated crisis management teams can execute these plans efficiently, minimizing downtime and coordinating recovery efforts.

- Leveraging Digital Twin Technology: A digital twin of your supply chain can simulate the impact of a disruption in real-time, allowing for rapid testing of mitigation strategies before implementation.

The ability to pivot swiftly and decisively in the face of disruption differentiates resilient manufacturers from those who succumb to supply chain pressures.

Building a Culture of Resilience: Beyond Tools and Tactics

Beyond specific strategies and tools, true supply chain resilience in 3D printer production requires a cultural shift within the organization. This involves:

- Collaboration Across Departments: Breaking down silos between R&D, procurement, production, and sales to foster a holistic understanding of supply chain dependencies and risks.

- Continuous Monitoring and Learning: Regularly reviewing supply chain performance, identifying emerging risks, and learning from past disruptions to continually refine strategies.

- Supplier Collaboration and Partnership: Treating suppliers not just as vendors but as strategic partners. This fosters trust, encourages shared risk management, and enables quicker responses during crises.

- Digital Transformation: Investing in digital tools for data analytics, predictive modeling, and automation to enhance visibility, efficiency, and responsiveness across the supply chain.

At Erlas Global, our approach integrates these principles into our core operations. Our risk assessment frameworks guide our decisions, and our alternative supplier strategies are continuously updated. We leverage logistics expert advice to ensure that our internal operations, and the solutions we provide to our clients, are robust against unforeseen challenges.

Erlas Global's Expertise in Supply Chain Resilience for 3D Printer Production

Navigating the complexities of the global supply chain for 3D printer manufacturing requires deep expertise and a commitment to strategic planning. At Erlas Global, we understand the critical importance of supply chain resilience for maintaining production continuity and delivering reliable 3D printing equipment.

We apply advanced risk assessment frameworks to identify potential vulnerabilities in our own supply chain and proactively develop alternative supplier strategies. Our long-standing relationships with a diverse global network of vetted component providers ensure reliable sourcing. Furthermore, we leverage logistics expert advice to optimize our distribution channels and minimize transit risks. Our focus on transparent processes and robust planning allows us to mitigate and resolve supply chain disruptions effectively, safeguarding our operations and ensuring the consistent quality of our 3D printer production.

When partnering with us for your 3D printer manufacturing needs, you benefit from a production process designed with resilience at its core, minimizing your exposure to the unpredictable nature of global supply chains. We don't just build 3D printers; we build trust through reliable delivery.

Conclusion: Building a Future of Uninterrupted Innovation

Supply chain disruptions are an inherent challenge in global manufacturing, especially for complex products like 3D printers. However, by adopting proactive strategies such as diversification, enhanced visibility, strategic inventory, and robust quality management, manufacturers can significantly bolster their resilience.

The journey towards an uninterrupted 3D printer production involves continuous monitoring, agile responses, and a collaborative ecosystem. By implementing these solutions, businesses can transform potential crises into opportunities for stronger, more efficient, and more reliable operations. Partnering with experts like Erlas Global, who prioritize supply chain resilience, ensures that your additive manufacturing endeavors remain on track, fostering innovation even in the face of global uncertainty.

Frequently Asked Questions About 3D Printer Supply Chain Disruptions

- What is supply chain resilience in 3D printer manufacturing?

Supply chain resilience refers to the ability of a 3D printer production supply chain to anticipate, withstand, adapt to, and recover from disruptions, ensuring minimal impact on operations and continuous delivery of products. - How can technology help mitigate supply chain risks?

Technologies like AI-driven analytics, IoT sensors, blockchain for traceability, and digital twins can provide real-time visibility, predictive insights, and automated decision-making, significantly enhancing a supply chain's ability to detect and respond to disruptions. - Is it better to source components locally or globally for 3D printer production?

There's a trade-off. Global sourcing often offers cost advantages and access to specialized components, but increases risk. Local sourcing can reduce lead times and logistics risks. A balanced strategy combining both (dual sourcing) is often the most resilient approach. - What is the role of risk management in 3D printer supply chains?

Risk management involves systematically identifying, assessing, and prioritizing potential risks within the supply chain, and then developing strategies to mitigate or avoid them. This ensures business continuity and protects against financial and reputational damage. - How do geopolitical events affect 3D printer production?

Geopolitical events can significantly affect production by disrupting trade routes, imposing tariffs, creating component shortages due to sanctions or export controls, and increasing the overall cost and complexity of global sourcing.